Faster than ever before

The Qpress 40 is a robust hot mounting press for exceptionally fast mounting processes. Thanks to its powerful heating/cooling technology and speed-optimized temperature control, the mounting time is significantly reduced. The robust bayonet closure, optional simple one-button operation, and clear parameter display on the 7″ industrial touchscreen ensure convenient and intuitive use. The connectable, patented extraction system sets new standards in occupational safety for the user.

Product Advantages

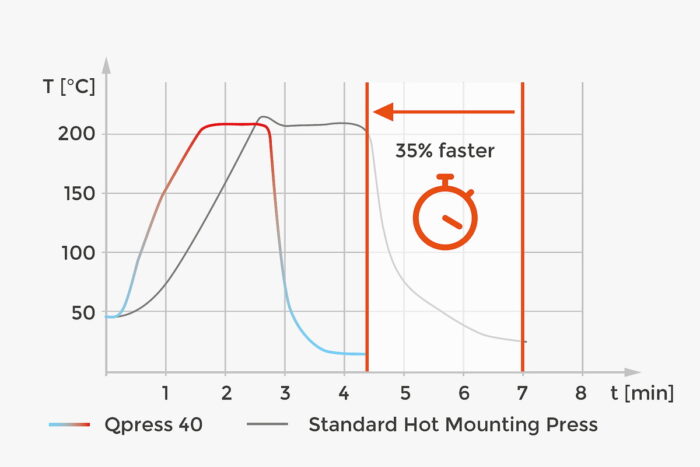

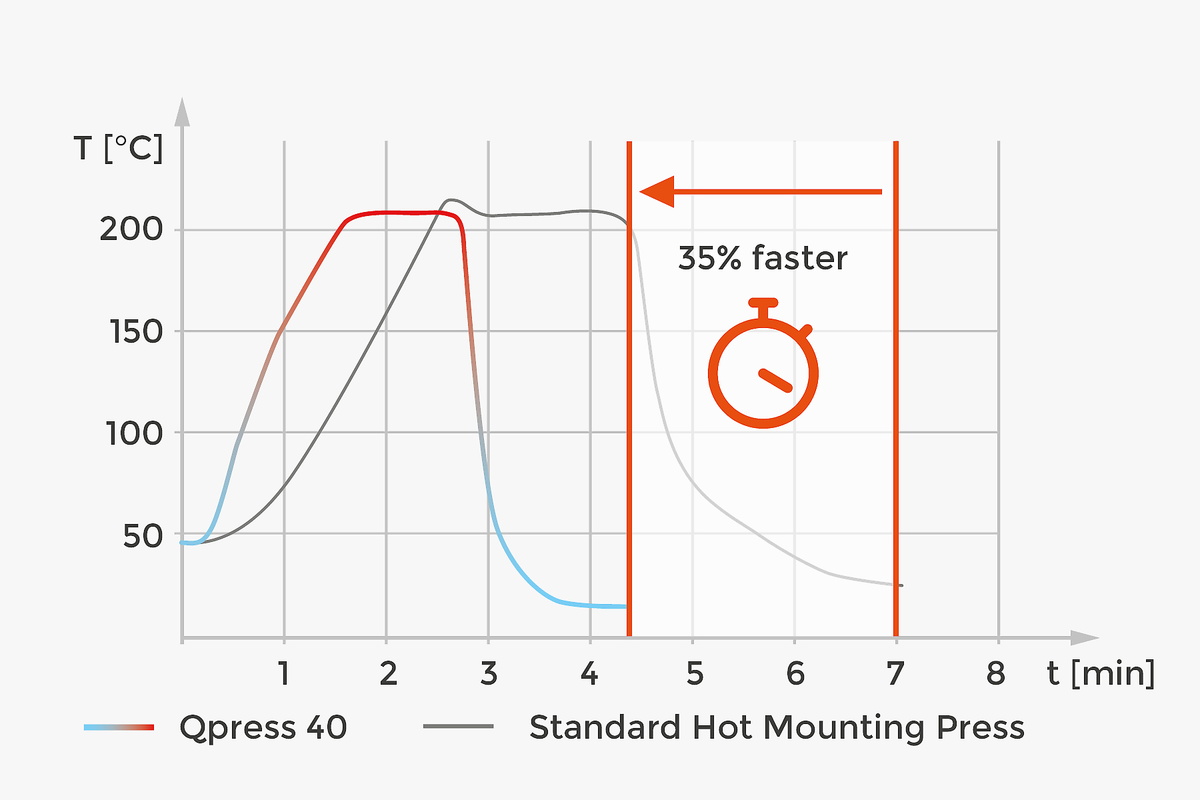

- Short mounting times (up to 35% time savings)

- Robust bayonet quick-release closure

- 7″ industrial touchscreen with innovative control software and optional one-button operation

- Dust Guard: extraction of granule dust during filling (patented)

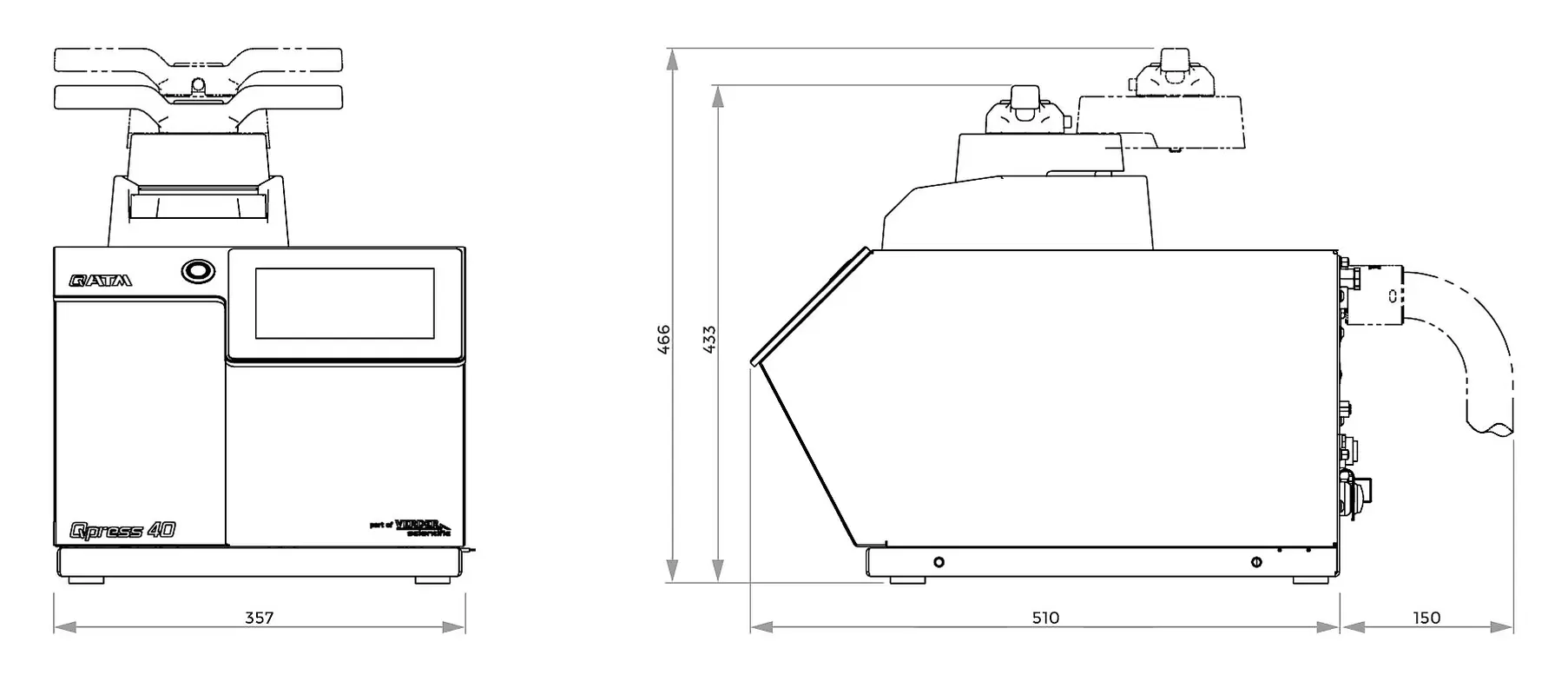

- Compact and high-quality design with powder-coated metal housing

- High sample throughput possible due to double mounting

Experience the 3D model in the real world!

Features

Speed-optimized heating and cooling technology

Shorter mounting times are achieved by:

- Optimized heat transfer between heating elements and mould

- Fast temperature control to precisely reach the target temperature

- Preheating function to shorten the heat-up time

The new technology can reduce the mounting time by up to 35%.

Simple one-button operation

The highest possible operating safety is achieved with the butler function. In just a few steps, the entire mounting process can be controlled by pressing the multifunction button. In addition, the PLUS software has a method database with pre-installed, consumable-specific mounting recipes and allows the storage of more than 128 user-defined mounting methods. This ensures the fastest possible operation with maximum process reliability.the mounting time by up to 35%.

Extraction of fine dust

The patented and optional integrable suction device (Dust Guard) protects the user from inhaling dust that can escape when the mounting resin is filled into the mould. This significantly enhances health protection in the workplace. In the PLUS software version, the extraction system is automatically controlled by the software.the mounting time by up to 35%.

Easy to clean

The suction nozzle attached to the back of the machine is removable, making cleaning very convenient. The mould and the two plungers can be removed for cleaning in just a few simple steps.

Tall press cylinder for double mounting

The tall press cylinder allows two samples to be mounted on top of each other simultaneously. This saves valuable mounting time and doubles sample throughput. Additionally, this mounting method is particularly time- and energy-efficient.

Robust bayonet closure

The robust and ergonomic bayonet closure fits comfortably in the hand and allows quick and easy opening and closing of the press cylinder.

Granulate compartment

The machine includes a granule compartment for easy pick-up and disposal of excess mounting granules.

Functional Principle

The new design of the Qpress 40 ensures the shortest possible heating and cooling times. The heating elements quickly melt the mounting resin thanks to optimized heat transfer and temperature control in the mould. During this process, the granules are compressed to the preset mould pressure. Once the set temperature is reached, the press mould is cooled as quickly as possible after a short holding time, allowing the hardened sample to be removed for further preparation. This not only saves time but also reduces energy requirements.

Mounting in a few steps

Software

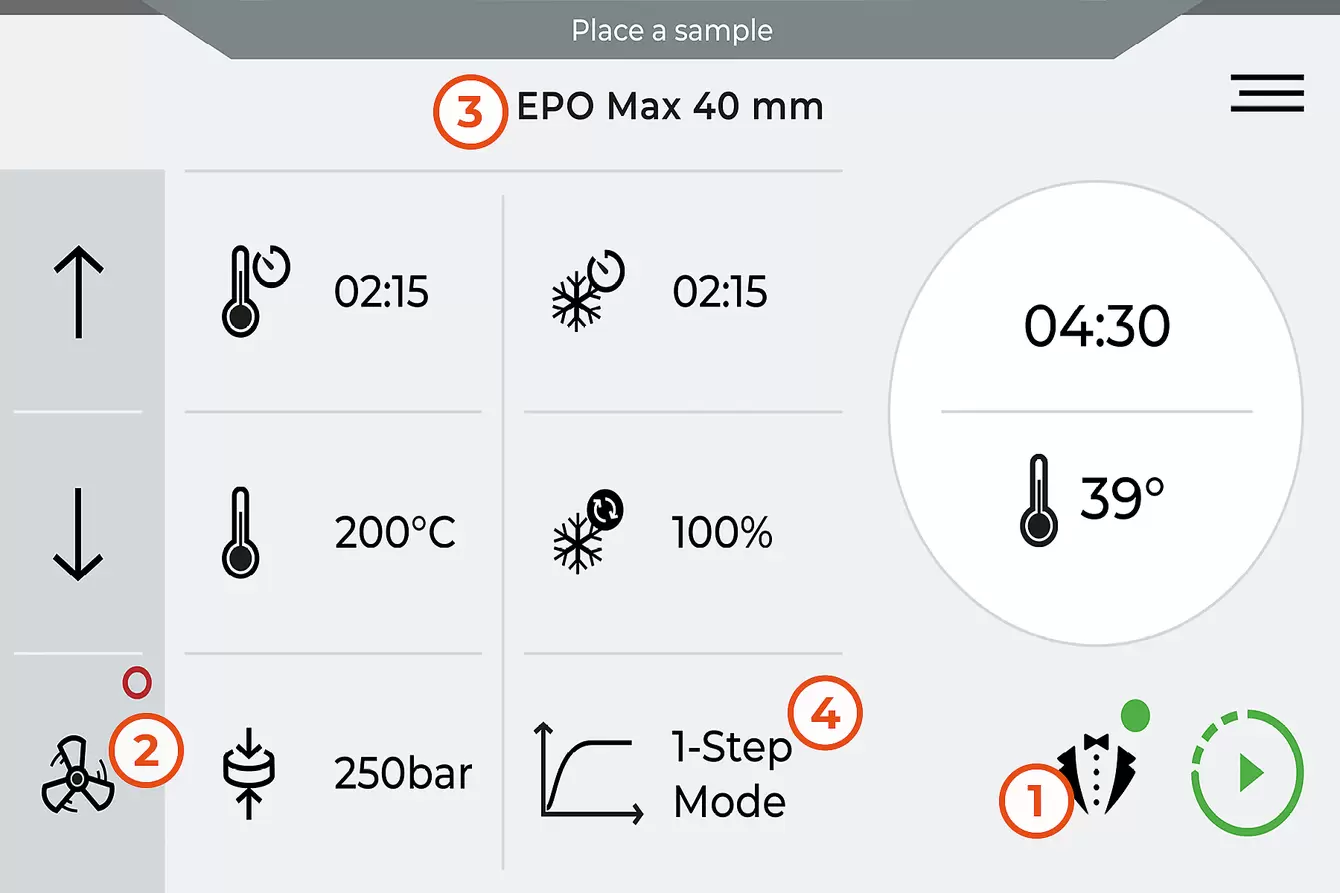

The Qpress 40 software is available in two variants. The standard Go software allows for quick setting of process parameters and starting of the mounting process.

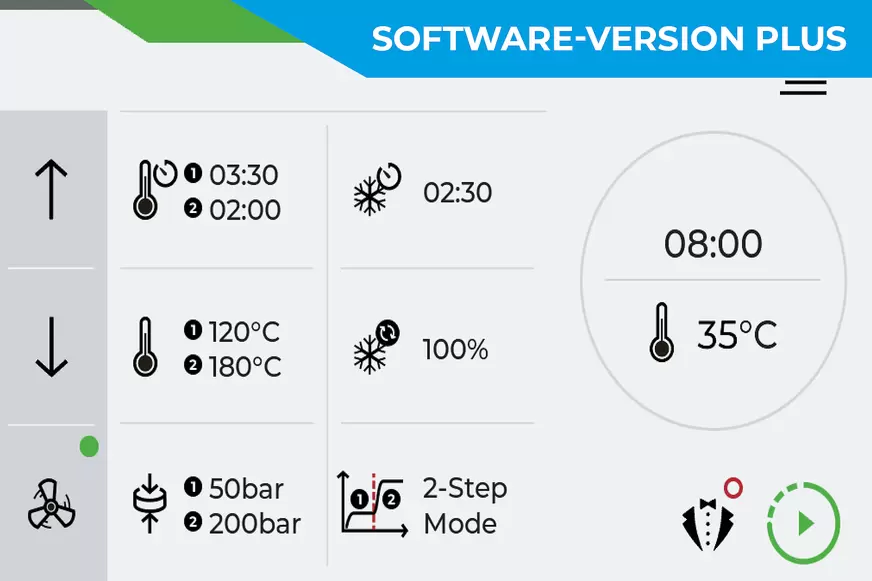

The Plus software variant offers additional features such as a method database, butler function, and automatic control of extraction.The Plus software also includes the 2-step mode for sensitive samples. You can upgrade to Advanced Software Plus at any time.

| GO (Standard Software) | PLUS (Advanced Software) | ||

| Setting of the mounting parameters via industrial touchscreen (heating/ cooling times, temperature, pressure) | ✔ | ✔ | |

| Speed-optimized temperature control | ✔ | ✔ | |

| Possibility of double mounting | ✔ | ✔ | |

| User account control | ✔ | ✔ | |

| Status bar | ✔ | ✔ | |

| Adjustable cooling capacity | ✔ | ✔ | |

| Automatic descaling function | ✔ | ✔ | |

| 1 | Butler function (simple one-button operation) | ✖ | ✔ |

| 2 | Dust Guard: Extraction of fine dust (controlled via software) | ✖ | ✔ |

| 3 | Method database (saving and loading programs) | ✖ | ✔ |

| 4 | 2-Step Mode (for sensitive samples) | ✖ | ✔ |

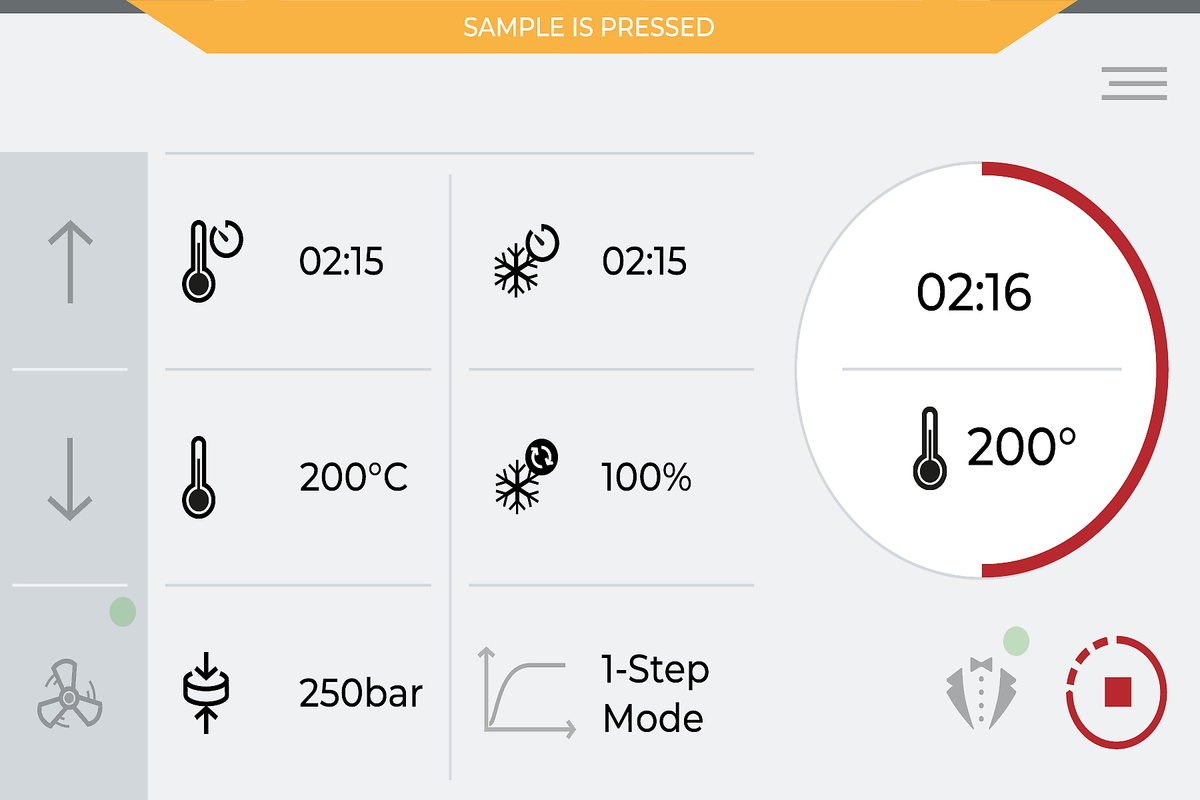

Clear software

The intuitive software with a modern interface displays all important mounting parameters on the robust 7″ industrial touchscreen. Here, you can set the heating and cooling times, desired cooling capacity, temperature, and press mould pressure. Additionally, the software displays the current status of the hot mounting press. User Account Control allows settings to be write-protected.

2-step print mode

For sensitive samples (sheets, thin-walled pipes, coated materials), a 2-step mode can be activated permitting independent control of temperature and pressure. For example, in the first stage, the mounting resin melts at low press chamber pressure. In the second stage, full pressure is applied for compaction, providing maximum protection for the sample.

Software-supported descaling function

The machine features an automatic descaling function. Simply insert a descaling tablet and select the software function to start the descaling process.

Innovative Features – Perfect Results

The new Qpress 40 hot mounting press has been developed to meet the increasing demands for precision, efficiency and user-friendliness. The Qpress 40 is characterized by innovative features that not only optimize work processes, but also improve the quality of the results.

1. Speed-optimized heating / cooling technology

2. Intuitive one-button operation

3. Tall press cylinder for double mounting

4. Robust quick closure

5. Extraction of fine dust

6. Clear process control

Accessories

Circulating cooling

- Powerful cooling

- Resource-saving circulation system instead of fresh water

- Low maintenance due to closed-circuit coolant circulation, reducing limescale deposits

- Can connect up to two hot mounting presses

Moulds

Easily interchangeable moulds are available with or without chamfer in these sizes: Ø 25 mm, Ø 30 mm, Ø 40 mm, Ø 1″, Ø 11/4″, Ø 11/2″.

Suction

The optional extraction device allows for direct dust extraction when filling the mounting resin. It also enables easy cleaning of the machine with a removable suction hose. The extraction system can connect to up to two mounting machines and is controlled via the Qpress 40 software. It includes a replaceable vacuum cleaner bag and an additional fine dust filter.

Perfect mounting – Consumables by QPREP

Mounting is more reliable, safer and more efficient when performed with the right equipment: Knowledge, exercising care and the right choice of consumables and equipment are crucial.