The world reference stability analyzer TURBISCAN LAB enables fast and sensitive identification of destabilization mechanisms (creaming, sedimentation, flocculation, coalescence, and more). A temperature-controlled measurement cell allows either stability monitoring at specific storage temperatures or acceleration of the destabilization process with a temperature increase up to 60°C.

The TURBISCAN LAB can be used in both R&D and QC labs for the development and routine control of raw materials and final product formulations. The TURBISCAN technology not only detects stability evolution at an early stage (up to 1,000 times faster compared to visual testing), but also quantifies global formula alteration with the Turbiscan Stability Index (TSI) scale.

* Image shows new product design – available starting April 2024

Stability Analyzer TURBISCAN LAB The World Leader in Stability Analysis

- Static Multiple Light Scattering (SMLS) technology

- 1 measurement position

- Temperature range from room temperature (RT) up to 60°C, to observe destabilizations in real usage and storage conditions

- Accelerated destabilization detection – up to 1,000 x faster than visual observation

- Real stability: sample stability analysis without the need for dilution or mechanical stress, in concentrations up to 95%

- Quantitative measurements of dispersion stability and shelf-life, migration velocity, particle size diameter, and other parameters

- One-click stability ranking with the Turbiscan Stability Index

- Barcode reader for easy sample management

- Convenient: Plug & Play, free license software on multiple computers, limited footprint …

Stability Analyzer TURBISCAN LAB Typical Applications

Whenever you are working with suspensions, emulsions, colloids, or foam, the TURBISCAN is your ideal characterization companion. The TURBISCAN series is used in various industries such as pharmaceuticals, cosmetics, food and beverage, paints and coatings, oil and gas, batteries, agrochemicals, chemistry, and much more.

emulsions

- Cosmetic creams and lotions

- Dairy products and beverages, flavor emulsions

- Pharmaceutical parenteral and topical forms

- Metalworking fluids

- Agrochemical: fertilizers, pesticides, …

- Petroleum emulsion

suspensions

- Paints, inks, and coatings

- Drug & vaccine suspension

- Make-up and sunscreen

- Chemical & polymer industry

- Ceramics and catalysts

- Battery slurries

- Electronic slurries

colloids & nanoparticles

- Drug delivery system: LNP, Liposomes, …

- Research on nanoparticles and nanoparticle suspension

- Polymer and biopolymer dispersion

… and many more!

Application examples

Fast Detection of Settling Particles Sedimentation

The TURBISCAN technology offers a significantly faster (up to 1,000 times) and more reliable detection of sedimentation compared to visual observation. Furthermore, naked-eye observation makes it difficult to calculate the migration rate and is prone to error and misinterpretation. In contrast, the TURBISCAN technology provides a fast and non-destructive way to detect and quantify sedimentation and particle size over time and can detect even small changes in highly concentrated samples without any dilution or mechanical stress. This makes it ideal for analyzing complex suspensions and formulations, and getting a quicker, reliable, and more accurate answer on sedimentation monitoring.

Fast Detection of Droplet Migration Creaming of Emulsions

When it comes to measuring droplet migration and creaming behavior in emulsion systems, the TURBISCAN technology has several advantages for formulators. On one hand, it provides a fast measurement (up to 1,000 times faster than visual observation) of native samples and a non-destructive way to detect and measure droplet migration. On the other hand, the migration rate can easily be determined and helps the formulator to compare formulas, making it ideal for analyzing complex emulsions with a wide range of droplet sizes and concentrations. Additionally, the TURBISCAN technology provides insights into the mechanisms driving droplet migration, which can be used to improve formulation and processing conditions. Overall, the use of TURBISCAN technology in emulsion analysis leads to faster, more accurate, and more reliable results compared to traditional methods.

Save Time to Measure Physical Stability Formulation: Stability Measurement and Shelf-Life Estimation

The TURBISCAN has been extensively used to measure the physical stability of formulations and colloidal systems. This technology helps the formulator to save time and precisely rank and quantify the samples’ stability in different trials or batches. It applies to native samples, even on very highly concentrated formulations. Not only saving time, the TURBISCAN also provides destabilization speed and metrics as well as robust analytics to make shelf-life predictions. The TURBISCAN technology follows ISO/TR 13097:2013’s recommendations and is ideal when it comes to quickly and accurately measuring stability. Stop the guesswork and make decisions based on facts!

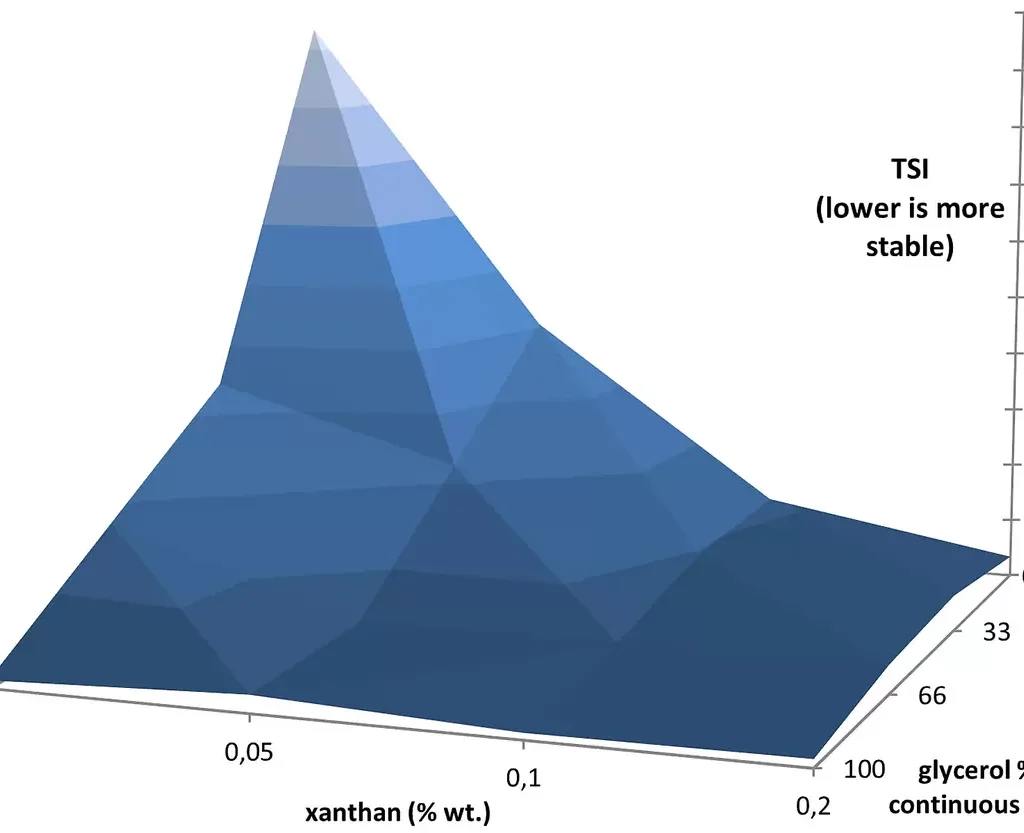

What Can Be Measured Can Also Be Improved Stability Mapping: Emulsions and Suspensions

Measuring the stability of emulsions and formulations is traditionally done by visual observations. In addition to being long and tedious, the visual inspection of emulsion destabilization usually ends up with a pass / fail answer. This is suboptimal for fine-tuning the ideal concentration of surfactants or stabilizers to be added to reach the desired shelf-life. The TURBISCAN is a great help in this regard; not only does it save a huge amount of time to detect the destabilization, but it also provides a value based on the instability and ranks different formulas as a function of their shelf-life. It hence produces objective and repeatable data to make a better, greener, and safer product.

Stable Products for Safer and More Efficient Pharmaceutical Suspensions Vaccine and Parenteral Dispersions

Stability and shelf-life testing are essential for pharmaceutical products and drugs. Destabilization or instabilities in vaccines, parenteral dispersions, or pharmaceutical products can have a major impact on product efficacy, and in some cases, on patient safety. While many techniques are available, the TURBISCAN offers in-situ, non-dilution, and non-destructive measurements to detect destabilization and save time therein. It provides a clear, precise, and objective stability measurement, essential to making fast and right decisions in R&D or quality control. The TURBISCAN has been intensively used to study the stability and redispersion capability of vaccines, as well as of parenteral and injectable dispersions and providing scientists with a deep insight into the dispersion state and its evolution.

Stability Analyzer TURBISCAN LAB Accessories and Options

Several options are available to sample and test the stability of your products. From standard, disposable 20 ml vials glass vials to small volumes (down to 2 ml) and to match your specific needs (syringe type, very high viscosity sample …). We got this covered!

Standard Vials (20 ml)

Cylindric glass vials have a recommended volume of approximately 20 ml. They are disposable to avoid chemical or bacterial contamination and decrease labor costs for washing and drying. The vials are closed thanks to a cap and a disposable PTFE seal to prevent evaporation in case of elevated temperature. These vials are meant to reproduce your visual stability test.

Small Volume (4 ml)

Small sample volume? No problem. Small-volume vials and the specific adapter are available. The measurement can be done with as few as 2 ml. Another good news: the sample can be fully recovered, and TURBISCAN measurement is non-contact / non-destructive.

On-Demand Adaptors (for Syringes, Pressurized Vials)

You have special needs, and we understand this! Our development team loves challenges: on-demand adapters can be offered (pre-filled syringes, pressurized vials, …). Perfect to study the stability in specific conditions (pressure) or for Quality Control.

Open-Bottom cells – For Viscous and Fragile Samples

There are samples that are either difficult to transfer or too fragile to be poured – the coring vials set helps to bypass this problem. The open base (which is manually closed with a stopper) allows a sticky sample or foam to be easily removed with the coring vials.

Calibration Standards

Each TURBISCAN comes with a set of standards to check instrument calibration. The TURBISCAN software, TURBISOFT, guides you step by step and once the procedure is finished, the software gives an “OK” signal. The test and results are saved, and the instrument checking procedure can be tracked.

Particle Size Distribution

The TURBISIZE software can measure the distribution of particle size (ISO13317) and the distribution of migration speed for any data obtained with a TURBISCAN, without any need to dilute, prepare, or modify the sample.