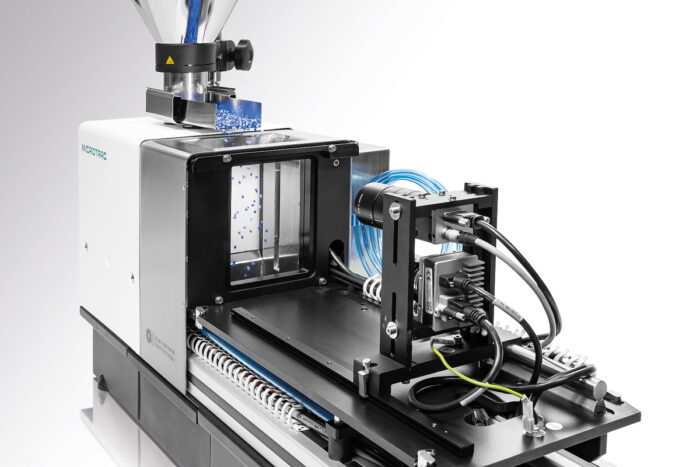

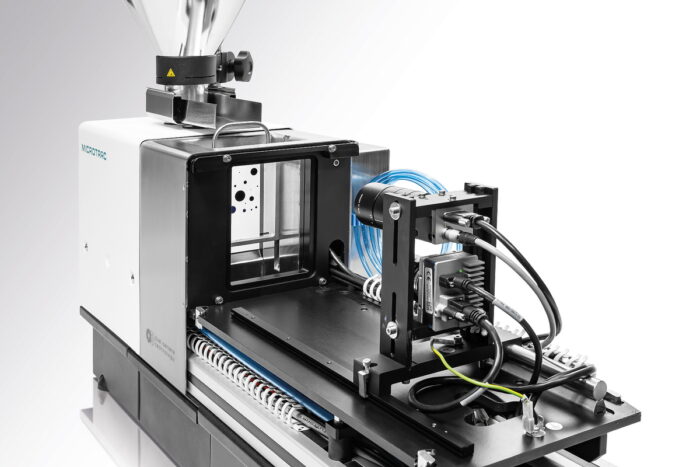

The CAMSIZER 3D particle analyzer combines all the advantages of dynamic image analysis (ISO 13322-2) in a completely redesigned measuring system, setting new standards in the characterization of bulk solids.

Unique 3D Analysis: Thanks to the extended field of view and long drop distance, each particle is analyzed up to 30 times and in different orientations, making the actual, three-dimensional particle morphology accessible for analysis. The evaluation of the “3D tracks” also provides much more meaningful shape analysis than ever before.

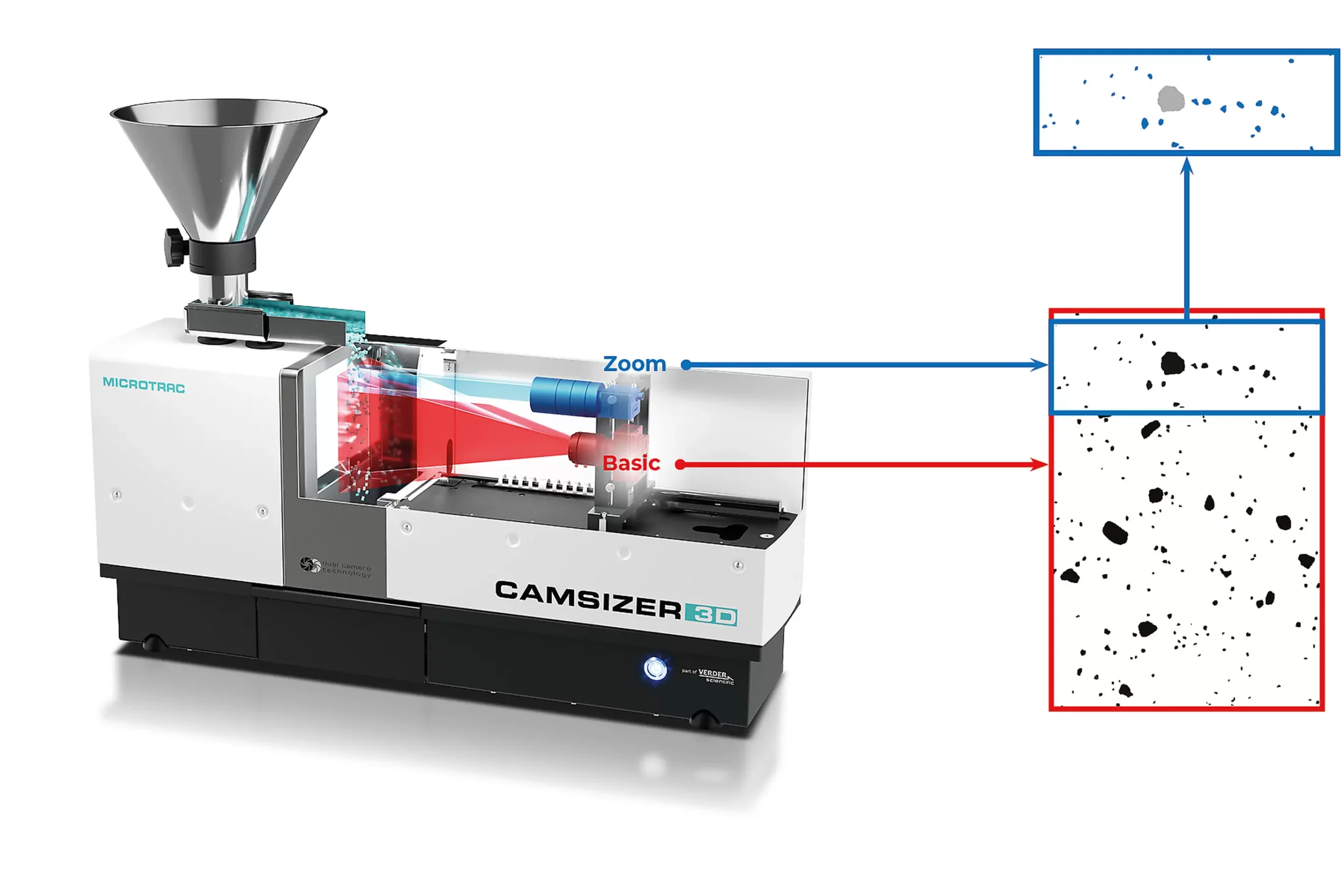

Proven 2-Camera System: The new ZOOM camera inside the CAMSIZER 3D (9 MPx) allows for the evaluation of fine particles with great accuracy. In combination with the BASIC camera (5 Mpx), this enables a wide measuring range from 20 µm to 30 mm. CAMSIZER 3D is the first choice for the analysis of dry, free-flowing bulk solids in both quality control and for research applications.

Particle Size and Shape Analyzer CAMSIZER 3D The Most Powerful Dynamic Image Analysis

- Patented 3D analysis with “Particle Tracking”

- Up to 30 images of every particle

- Particle size and shape analysis from 20 µm to 30 mm without hardware adjustment

- Short measuring time of 2 to 5 minutes

- High sample throughput

- 100% detection of oversize particles

- Excellent compatibility to sieve analysis

- Excellent reproducibility

- Evaluation of > 250 images / s in real time (in 3D mode)

- Powerful, long-life LED light source

- Maintenance-free

Unique & Patented 3D Particle Tracking Technology

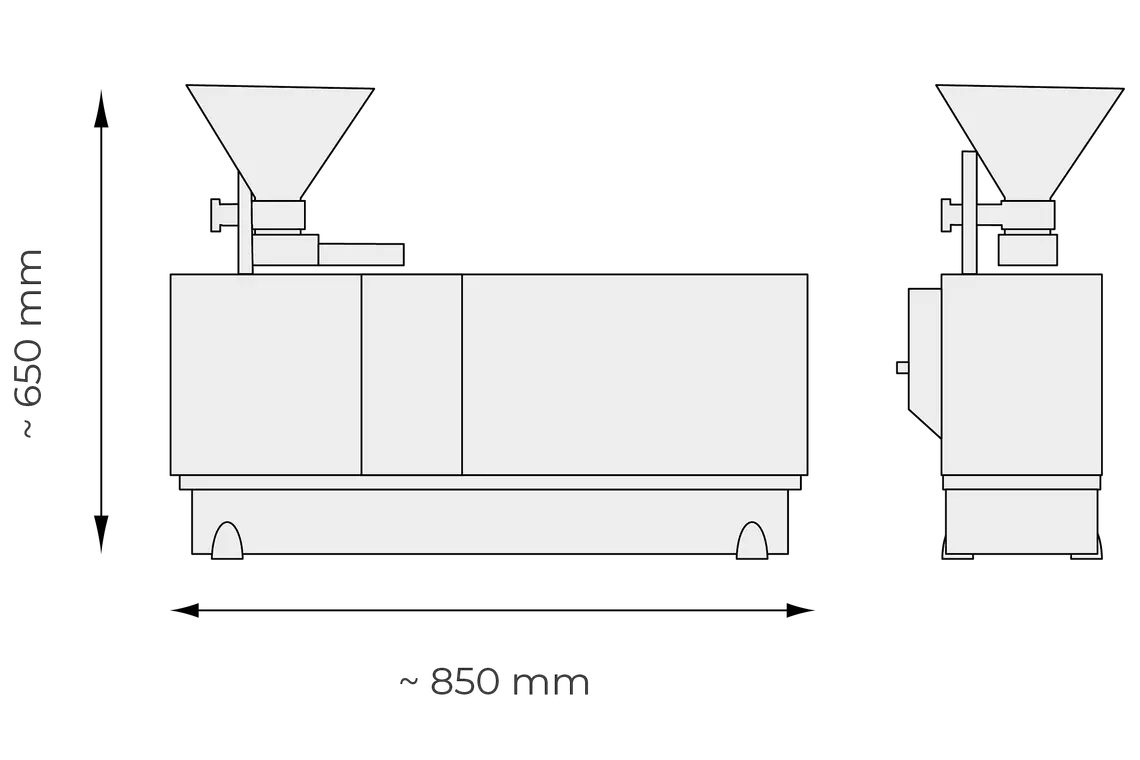

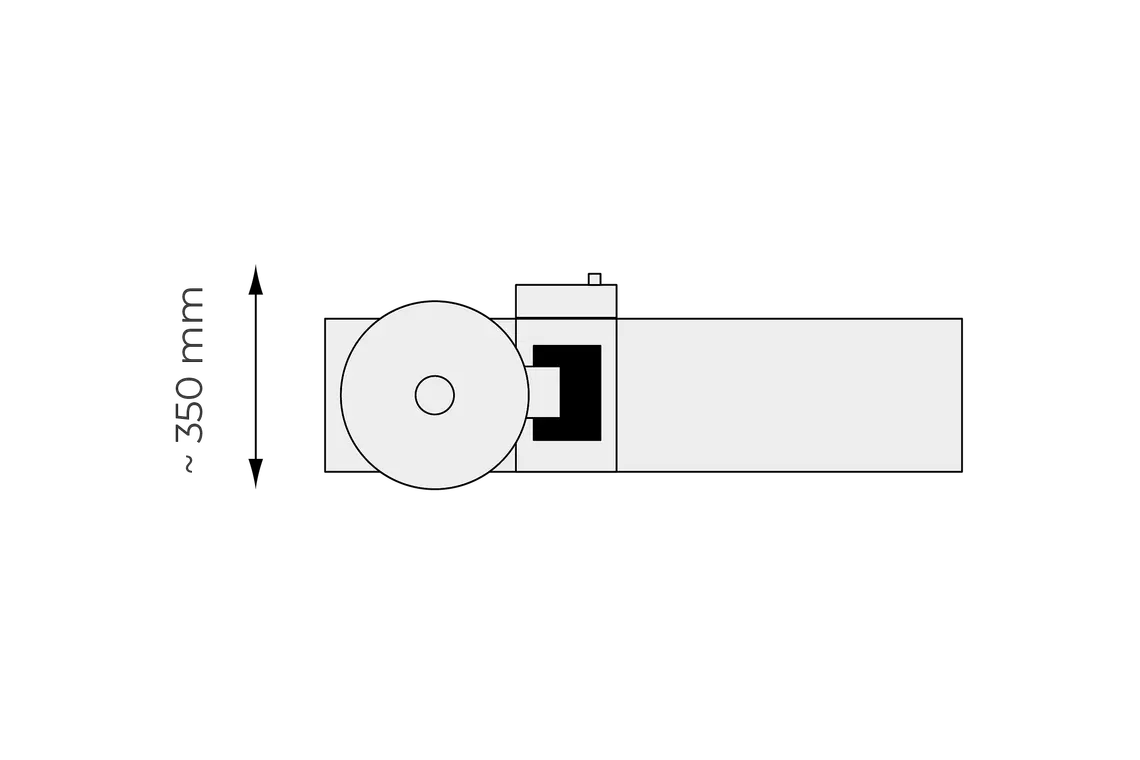

The CAMSIZER 3D utilizes a funnel, vibrating feed chute, LED strobe backlighting, powerful high-speed cameras, and sophisticated software to perform the measurements.

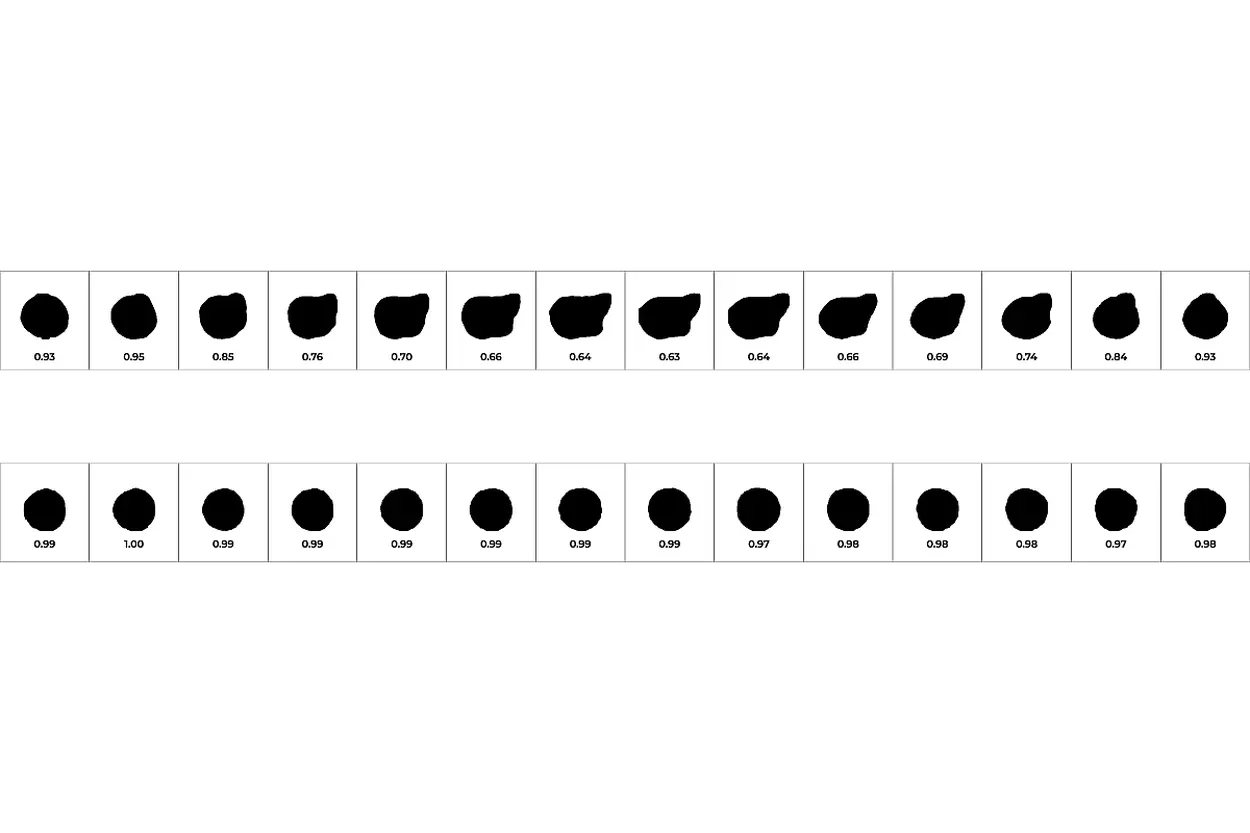

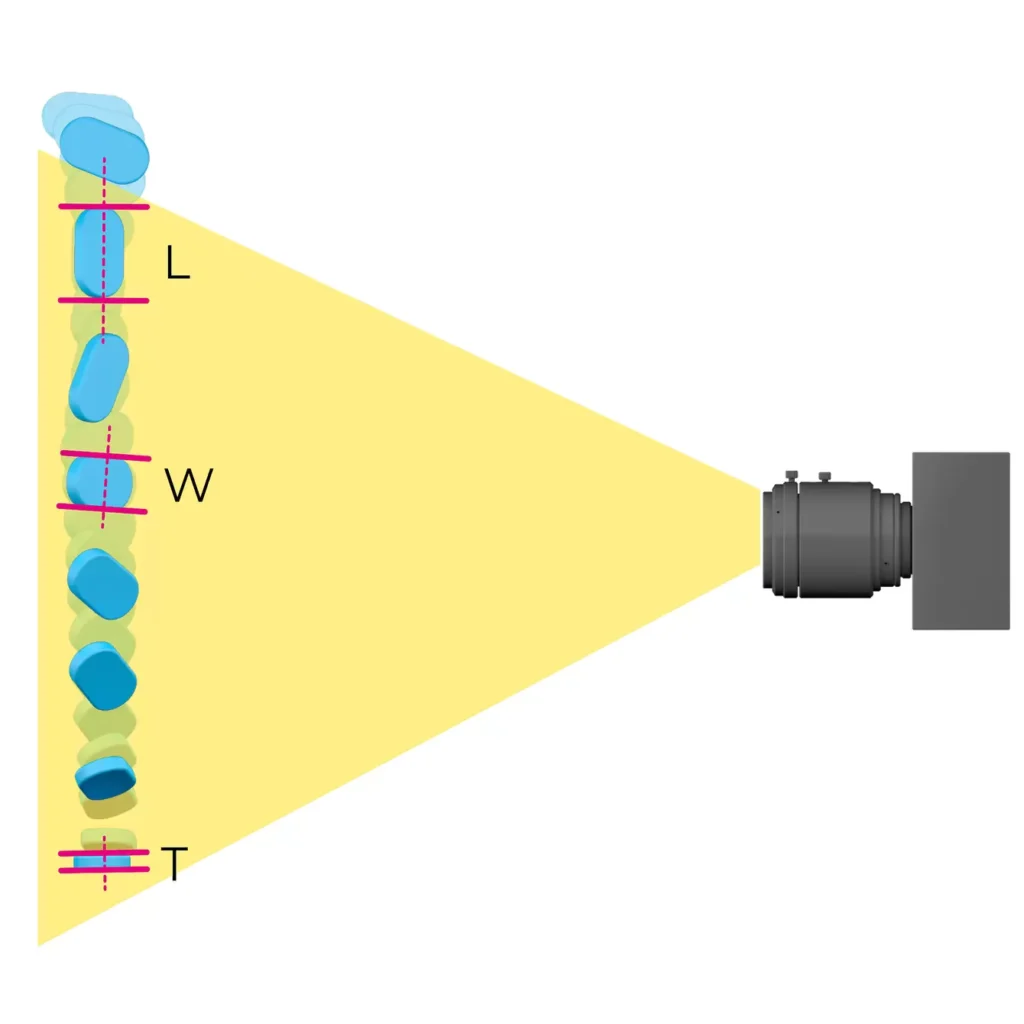

The particles travel down the vibrating feeder and fall into the sensing zone, creating a tumbling motion as they fall. The CAMSIZER software tracks each particle as it passes between light source and cameras, taking up to 250 images per second. As the particle is tracked, multiple images are recorded, measuring length, width, thickness, perimeter, area and various shape descriptors. The software automatically aligns the images for viewing, with up to 30 images per particle. This creates a “particle track”, a sequence of images of the same particle in different orientations. From this, distributions can be calculated, based on one or more size or shape parameters. Filters can be applied to isolate groups of particles of particular interest for more targeted analysis.

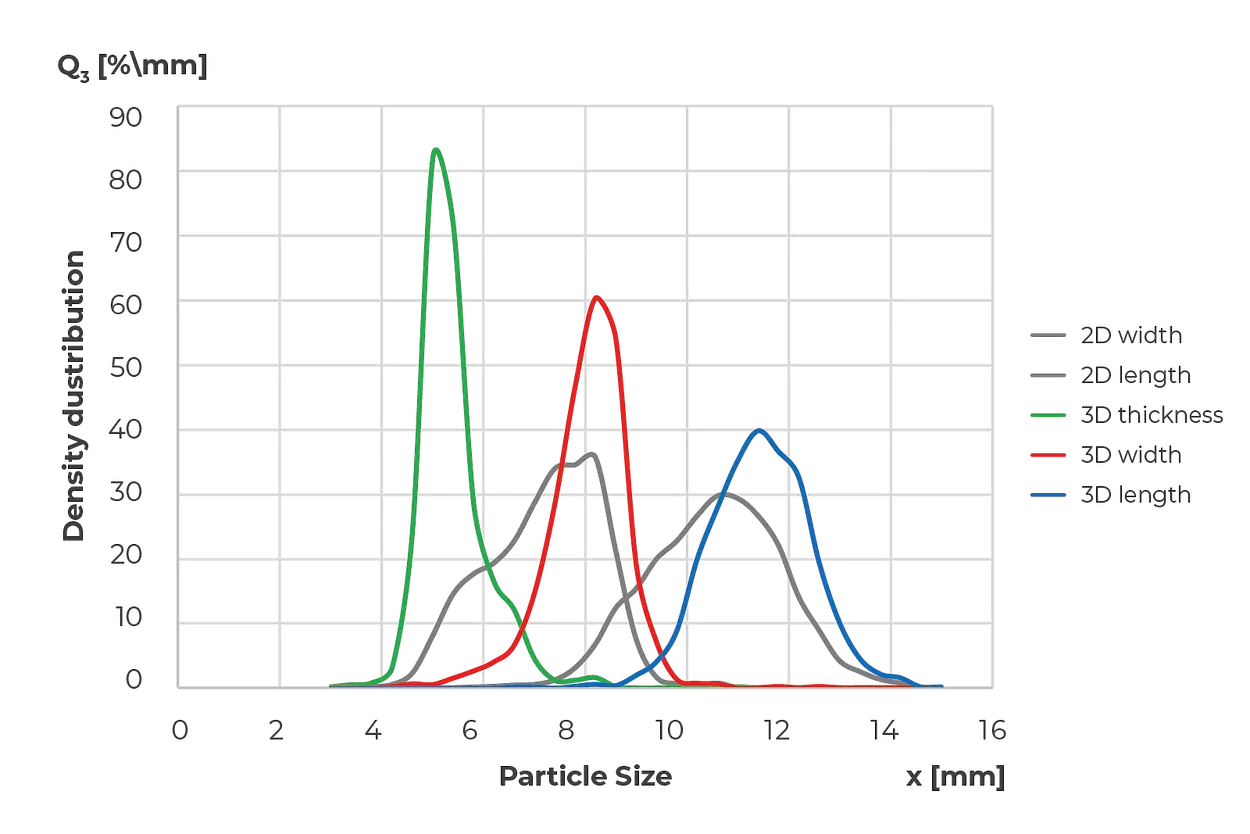

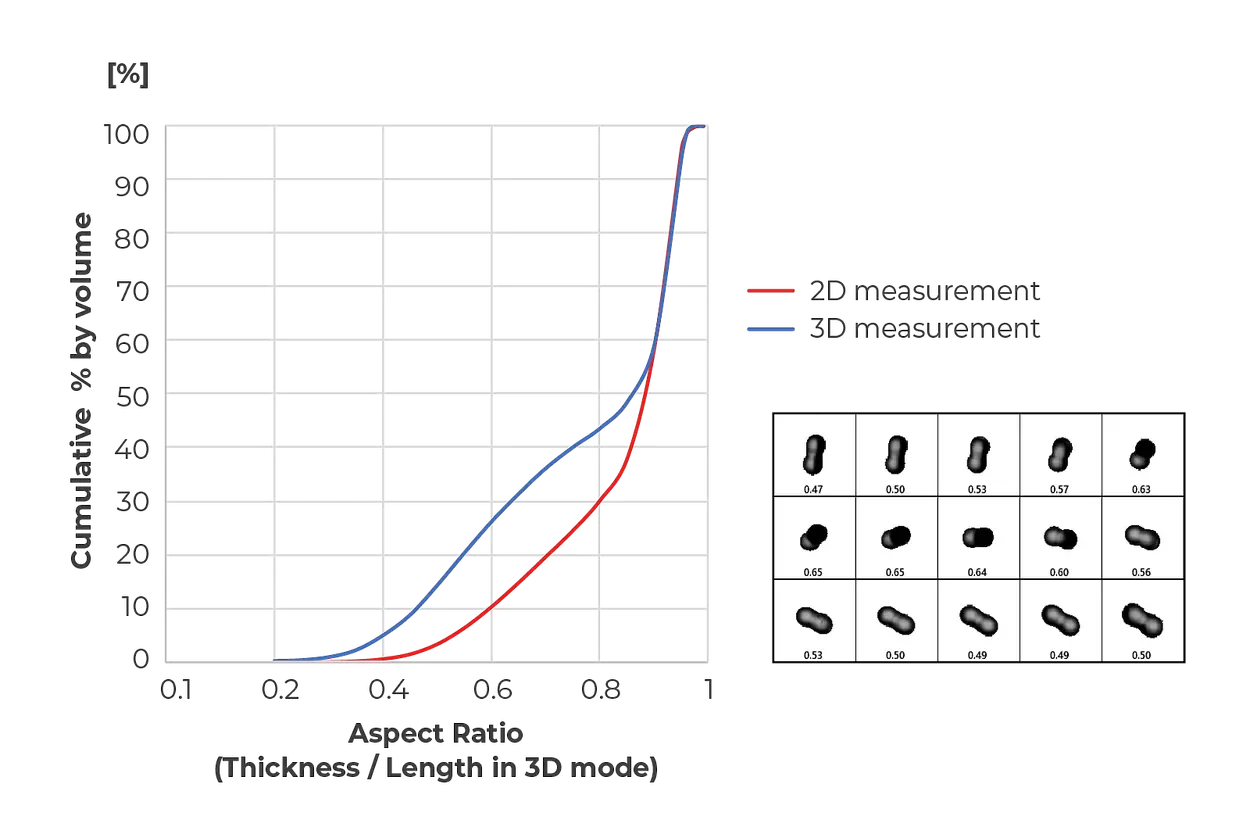

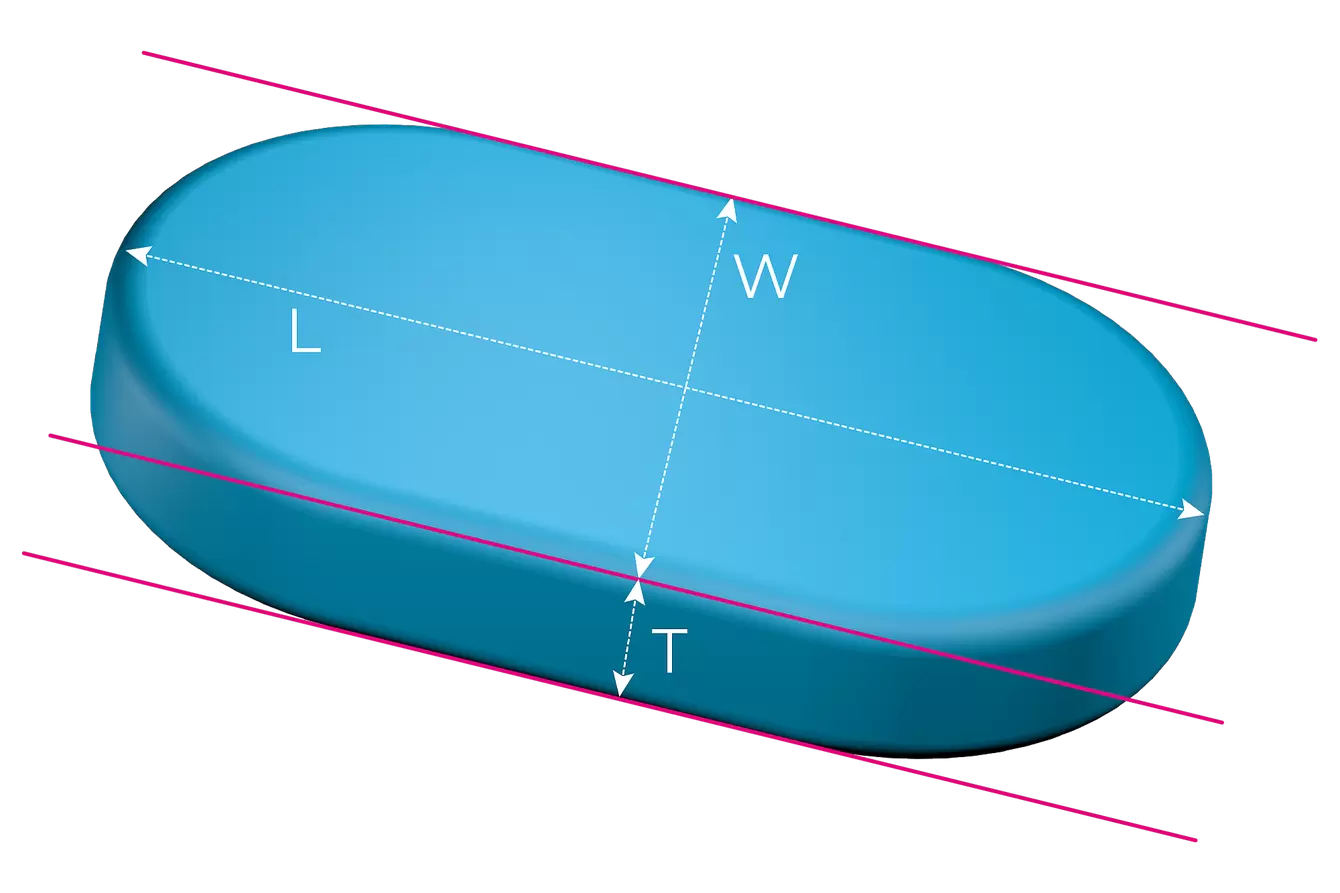

In the particle track, the software determines the width and the length of each particle projection:

- the largest value of all length measurements within a particle track is the “3D length” of the particle

- the largest value of all width measurements within a particle track is the “3D width” of the particle

- the smallest value of all width measurements within a particle track is the “3D thickness” of the particle

Thus, for particles with three different dimensions (e. g. almonds), the size distributions of all three dimensions can be output separately.

3D Analysis is particularly advantageous for particles that are supposed to have a specific shape like spheres, rods (extrudates), lenses or ellipsoids (“rugby-ball”-shape). With the 3D tracking technology, each particle inevitably shows a wide variety of projections, which automatically also opens new possibilities in shape analysis.

3D Beats 2D New Possibilities in Shape Analysis

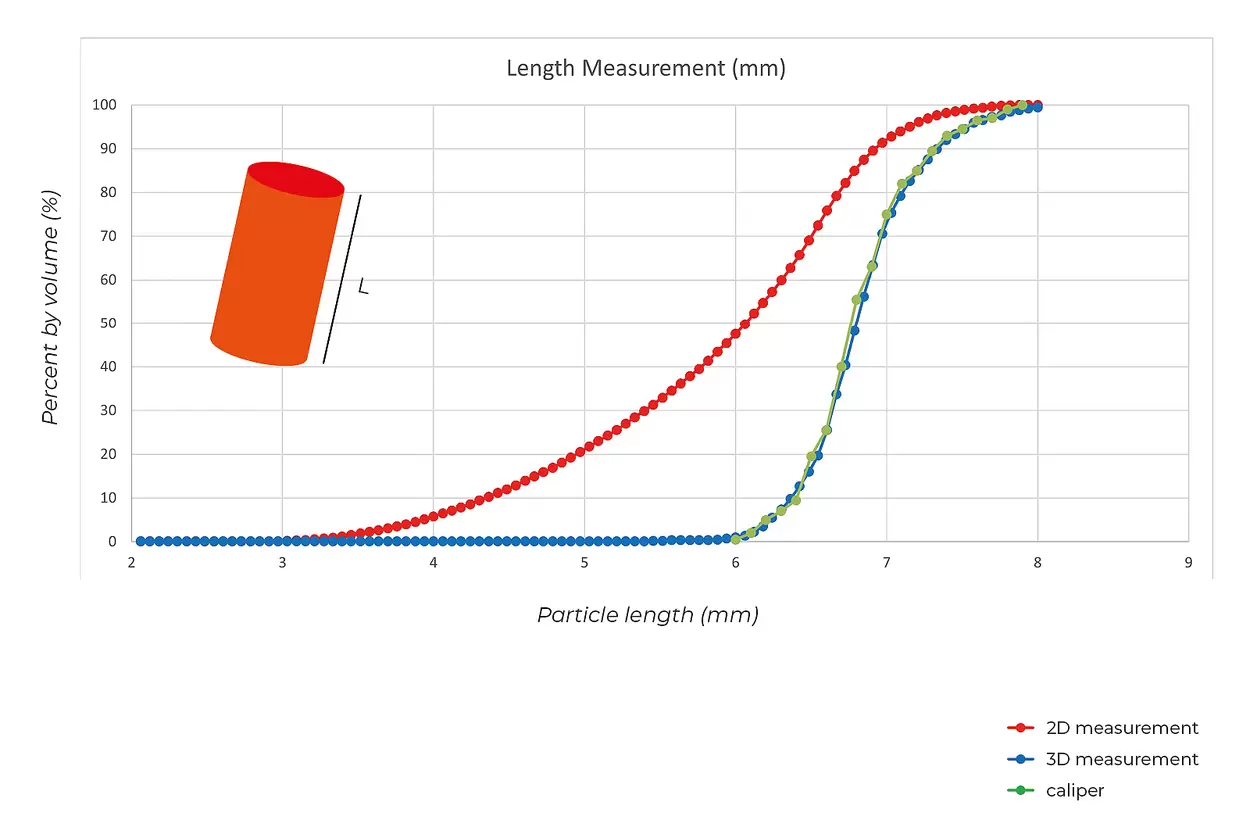

In contrast, traditional 2D analysis captures only one image per particle in random orientation, even if the particle in measured multiple times at increased acquisition rate, there is no “mapping” of one image to another. Each individual image is treated as a new, independent measurement event. The true length, width, thickness, and shape is obscured by this. Rather, the “length” measured in 2D mode is a mixture between true 3D length and true 3D width; the “width” measured in 2D mode is a mixture between true 3D width and true 3D thickness. Only if the particles can be mechanically aligned, meaningful results are obtained in 2D mode. In the past, however, this was only feasible for some special particle shapes like cylinders.

Measurement in 2D Mode

- Particle size & shape measurement in random orientation

- Suitable for irregularly shaped material, natural products

- Results compatible with sieve analysis

Measurement in 3D Mode

- Separate distribution of length, width, and thickness

- Excellent detection of defective particles

- More accurate volume calculation

Particle Size and Shape Analyzer CAMSIZER 3D

Extremely Wide Measuring Range with Dual Camera Technology

Microtrac’s unique dual camera technology is a landmark in the development of Dynamic Image Analysis. By simultaneously employing two cameras with different magnifications, extremely wide dynamic measuring ranges are achieved. This is accomplished without hardware adjustments or modifications and without compromising the accuracy.

Each camera is specialized for one size range. The ZOOM camera analyzes fine particles with highest resolution whereas the BASIC camera detects the larger particles with excellent statistics. A special algorithm combines the information provided by both cameras, covering a size range of more than three orders of magnitude.

This arrangement resolves a significant drawback of many image analysis systems that employ only one camera, e. g. microscopes. Such instruments either cannot correctly report the fine particles in wide size distributions, or the large particles are not captured reliably due to the small field of view.

- 9 megapixel ZOOM camera

- 5 megapixel BASIC camera

- Calibration within a few seconds with certified reference objects

- Wide measuring range without hardware adjustment

- Non-contact and non-destructive measurement

- Dust protected housing

- Rugged construction for use in production environments

- Automatic dust extraction in the measurement chamber to protect the user and the instrument

Better Than Ever Before

Compared to previous CAMSIZER models the CAMSIZER 3D features a significantly higher camera resolution and frame rate by employing a ZOOM camera with 9 megapixels and a BASIC camera with 5 megapixels at a frame rate of up to 250 fps.

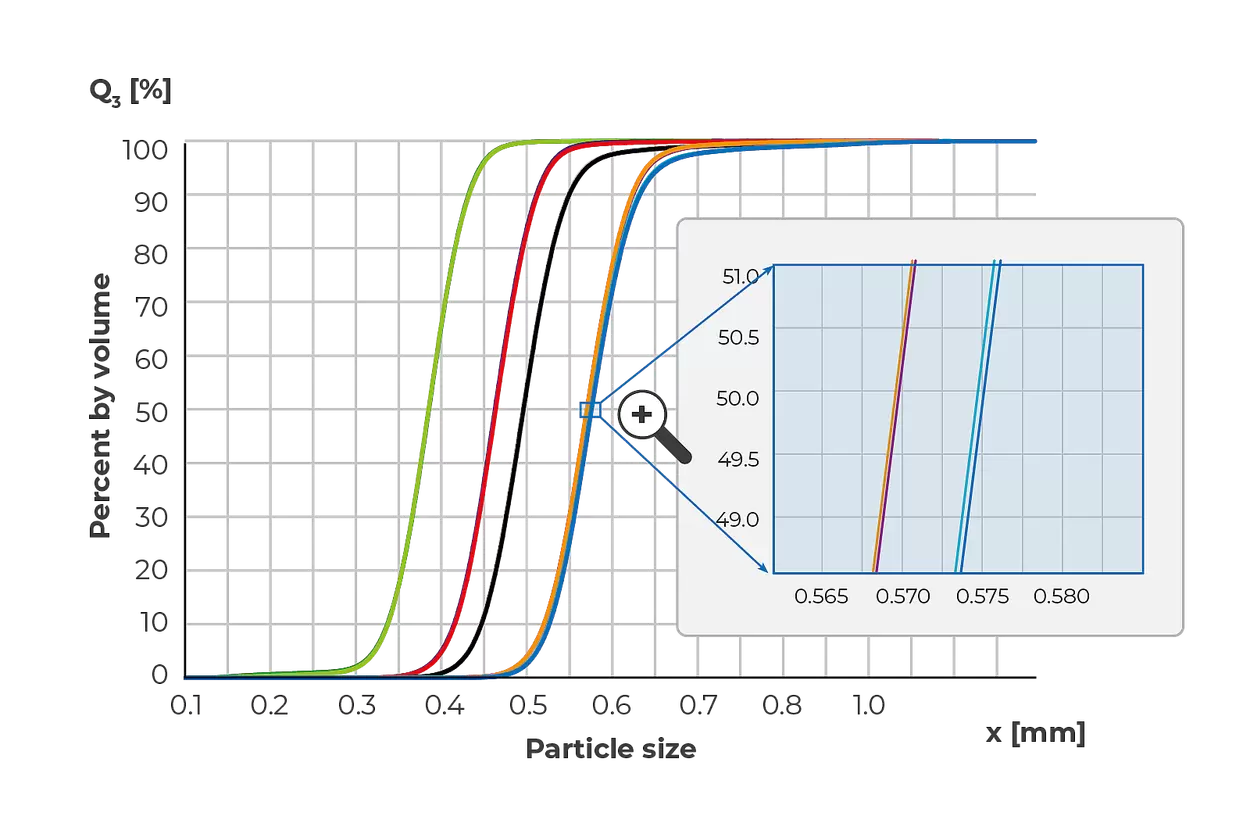

This allows superior image quality and particle detection, for all coarse and fine samples. Broad and narrow distributions are measured with the same accuracy and precision.

The image width of the ZOOM camera is the same as that of the BASIC camera, which ensures excellent reproducibility of the measurement results within a short measurement time.

Faster, more precise and additional information

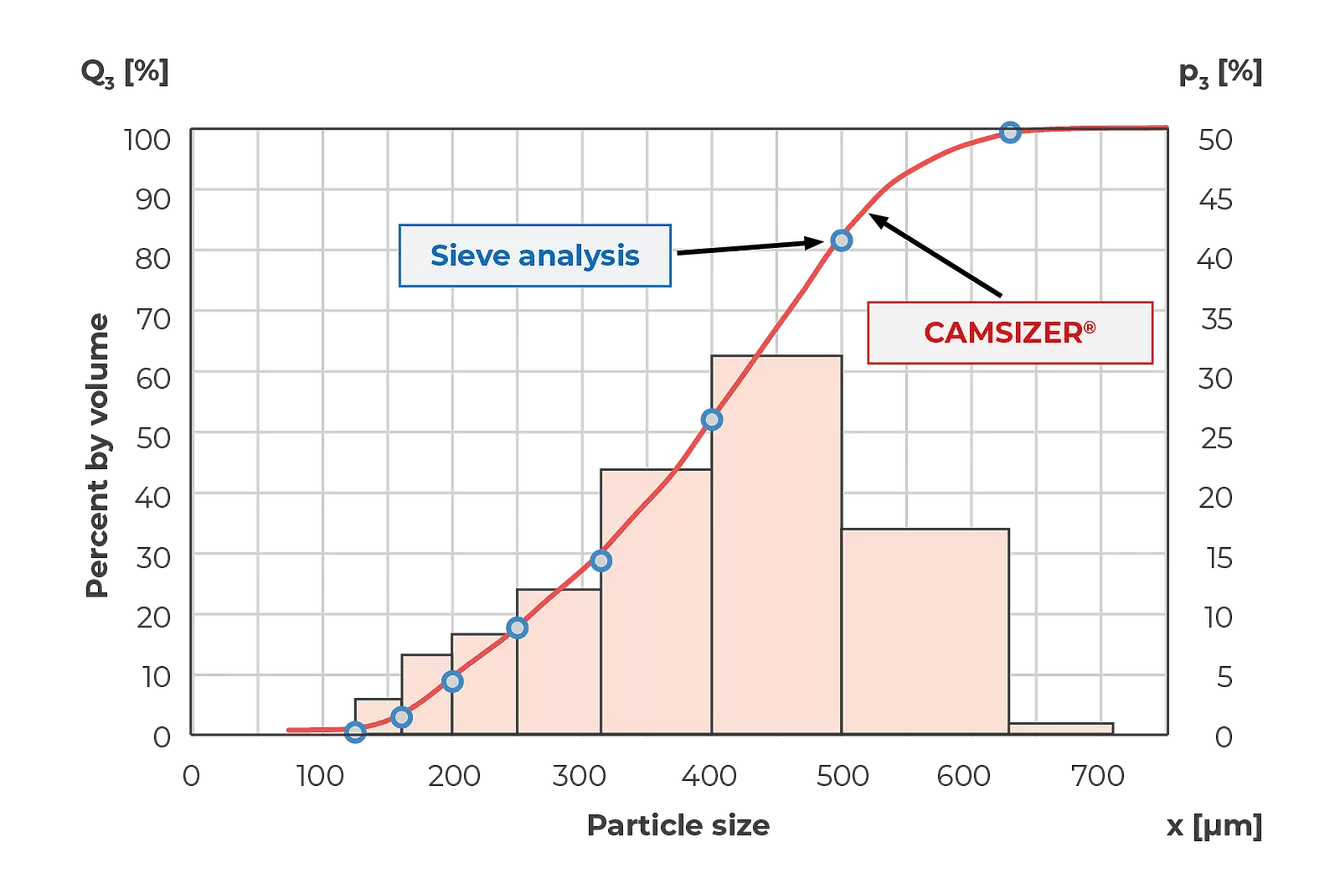

CAMSIZER replaces sieve analysis

Traditional sieve analysis frequently forms the basis for quality standards and product specifications between suppliers and customers. A rapid and efficient alternative like Microtrac’s CAMSIZER systems must take this into account and be able to produce results that are fully comparable.

This is why the CAMSIZER software is provided with algorithms for emulating sieving processes.

In this way many users have been able to replace time-consuming sieve analysis by using the CAMSIZER without having to sacrifice the familiar quality specifications. The automated and wear-free measurement means that the results obtained are more reliable and reproducible over time.

Perfect compliance of sieve analysis and CAMSIZER measurement results for granulated fertilizer

Accessories and Options

Microtrac offers various sets of feed hoppers and chutes for specific applications. With the help of the feed guides, the sample stream can be oriented in a way that, for example, longish particles like extrudates are always measured in the correct orientation.

The Perfect Solution for Busy Laboratories Autosampler for Batch Processing

The Autosampler is a fully automatic sample feeding system for the CAMSIZER 3D which can be easily retrofitted to existing instruments.

It processes up to 14 samples (extendable to 40 samples or more) in a row without the need for the operator’s intervention. The correct measurement settings can be read from the barcodes on the sample beaker. The Autosampler is suitable for continuous operation and allows effortlessly measuring more than 150 samples per day, even by untrained operators.

Typical applications for the CAMSIZER 3D Autosampler system include sand, superabsorbent polymers, rice, coke, tea, rubber granules, EPS, sugar, glass beads, salt, and many more.

Particle Size and Shape Analyzer Camsizer 3D Typical Applications

Many properties of bulk materials, like flowability, solubility, filtration efficiency, reactivity, abrasiveness, and taste, are significantly influenced by particle size. Therefore, particle size determination is commonly used as a part of quality control in many different industries.

Especially when products with specific geometry are produced, such as extrudates, abrasives, pharmaceutical pellets or fertilizer granules, shape analysis with the CAMSIZER 3D provides important measurement data determining the quality of the sample within a few minutes. Another advantage is that the method can be largely automated via automatic sample feeding systems or online connection.

sand

- abrasives

- activated carbon

- building materials

- catalysts

- chemicals

- coal / coke

- sand / gravel

pharmaceuticals

- extrudates

- fertilizers

- foodstuffs

- glass / glass beads

- pharmaceutical pellets

- polymers

- superabsorbents

sugar

- refractory products

- salt

- sugar

- supporting agents (proppants)

- wood chips… and many more!