The CAMSIZER X2+ is a powerful, extremely versatile particle size and shape analyzer with a wide measuring range that combines state-of-the-art camera technology with flexible dispersion options. Based on the principle of Dynamic Image Analysis (ISO 13322-2), the CAMSIZER X2 provides precise particle size and shape information of powders, granules and suspensions in a measuring range from 0.8 μm to 8 mm.

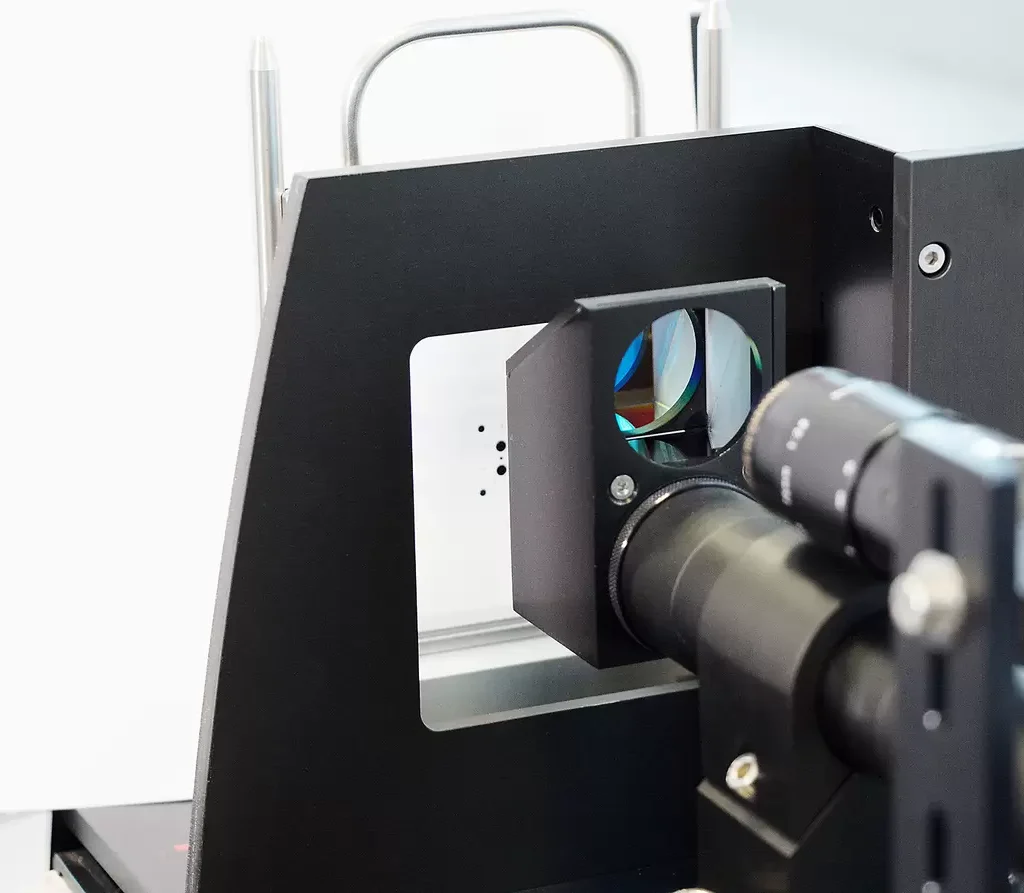

The CAMSIZER X2 produces a particle flow which is characterized by an optical system with high resolution. An ultrabright LED stroboscopic light sources and two high-resolution digital cameras achieve a frame rate of more than 300 images per second which are evaluated in real time by a powerful software. Thus, the CAMSIZER X2 captures the images of hundreds of thousands to several millions of particles with highest accuracy within only 1 to 3 minutes.

The CAMSIZER X2 provides a wide selection of particle information which allows for comprehensive and reliable characterization of the sample material. It is suitable for use in R&D as well as for routine tasks in quality control.

Particle Analyzer CAMSIZER X2+

- Particle size and particle shape analysis from 0.8 μm to 8 mm with Dynamic Image Analysis (ISO 13322-2)

- Precise analysis of wide size distributions

- Excellent resolution for narrow or multimodal size distributions

- Detection of small amounts of oversized or undersized particles

- Fully comparable to sieve analysis and laser diffraction results

- A wealth of evaluation options (different size models, a variety of shape parameters, particle library, single frame evaluation, etc.)

- Outstanding reproducibility

- Measurement time 1 – 3 minutes, high sample throughput

- Modular „X-Change“ system for dry and wet measurement

- Ultra-strong LEDs and high-resolution cameras for the clearest results

- Easy operation, virtually maintenance-free

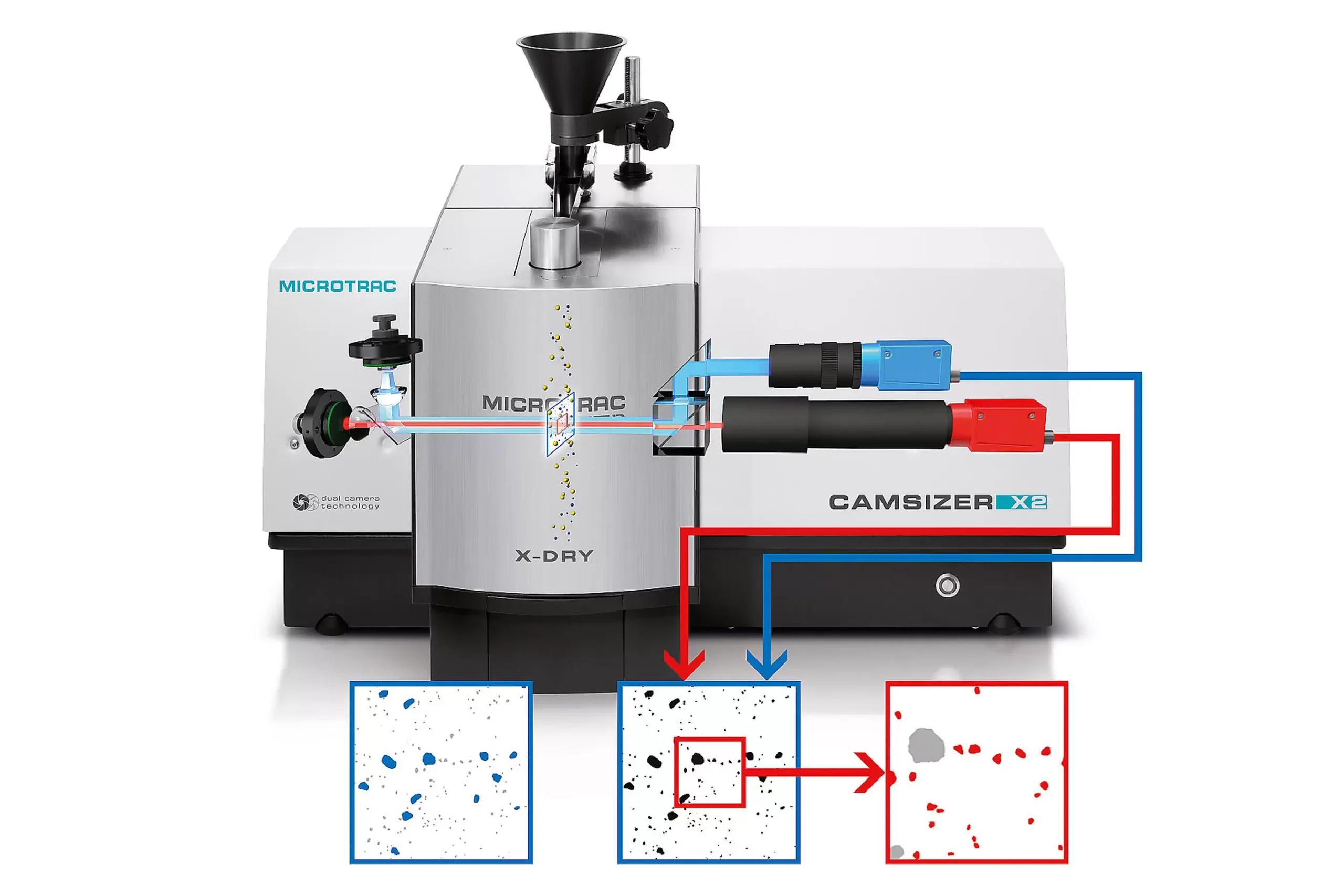

Extremely Wide Measuring Range due to Dual Camera Technology

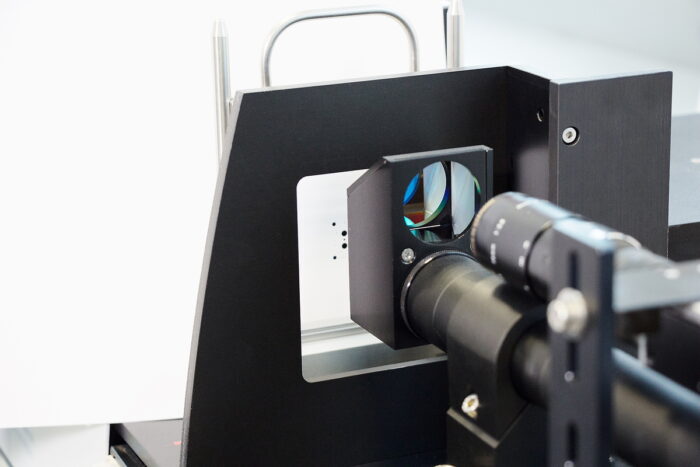

Microtrac’s unique dual camera technology is a landmark in the development of Dynamic Image Analysis (DIA). By simultaneously employing two cameras with different magnifications, extremely wide dynamic measuring ranges are archieved. This is accomplished without hardware adjustments or modifications and without compromising accuracy. Each camera is specialized for one measuring range.

The ZOOM camera analyzes fine particles with highest precision whereas the BASIC camera detects the larger particles with excellent statistics. A special algorithm combines the information provided by both cameras and delivers the exact size distribution in a possible range of more than three decades!

This arrangement resolves a significant drawback of many image analysis systems that employ only one camera, e. g. microscopes. Such instruments either cannot correctly report the fine particles in wide size distributions, or the large particles are not captured due to the small field of view.

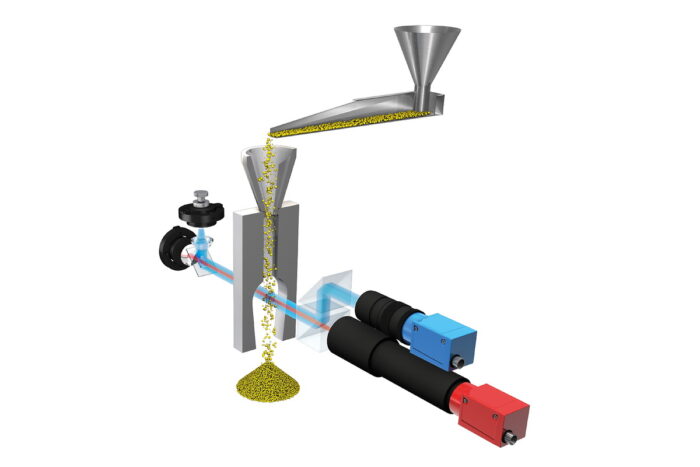

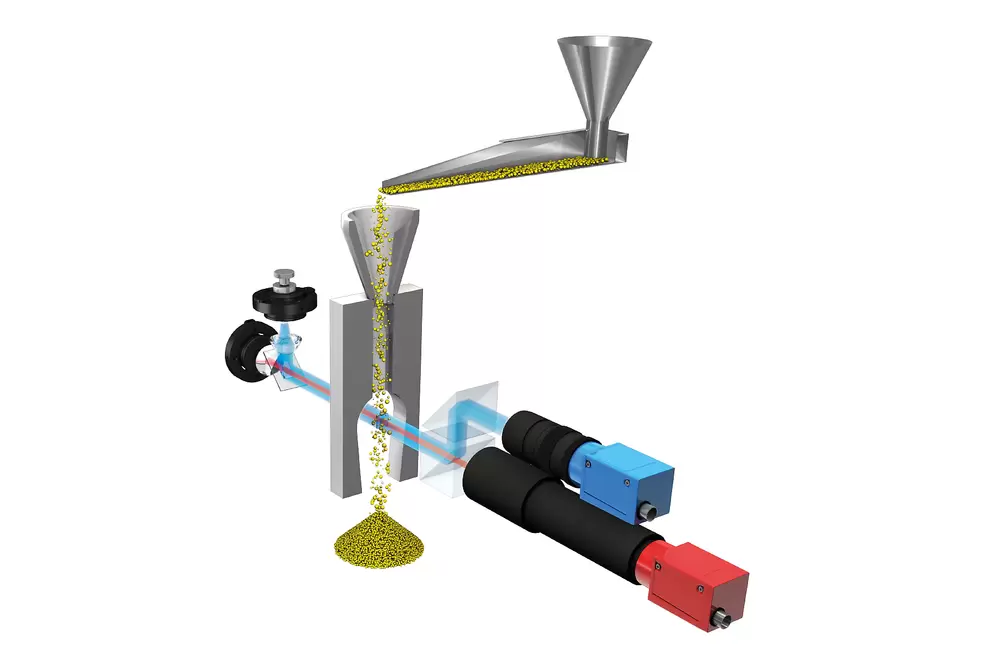

Measurement Principle

Two cameras operate simultaneously during measurement: the BASIC camera (blue) analyzes the larger particles, the ZOOM camera (red) captures the small particles. This procedure ensures optimum measurement conditions for all particle sizes in a distribution.

Modular X-Change System

Correct sample preparation and dispersion of the particles before they pass the measurement field are as important as the actual analysis. Particularly for fine powders which tend to agglomerate, sufficient dispersion is crucial to the reliability of the measurement results. Therefore, various modes of sample feeding help to achieve separation of the agglomerates without destroying individual particles. Our Modular X-Change System fulfils this requirement in a perfect way.

Elaborate Design for Maximum Flexibility

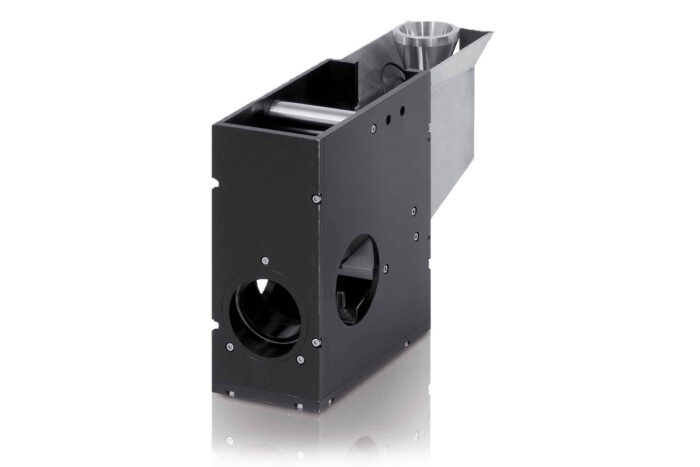

The CAMSIZER X2’s modular “X-Change” system offers three alternative dispersion options, permitting the selection of the optimum method for each sample type. The user may choose between wet dispersion with X-Flow or dry measurement either in free fall with X-Fall or in an air flow with X-Jet. The modules and cartridges are quickly and easily exchanged which makes working with the CAMSIZER X2 convenient and safe.

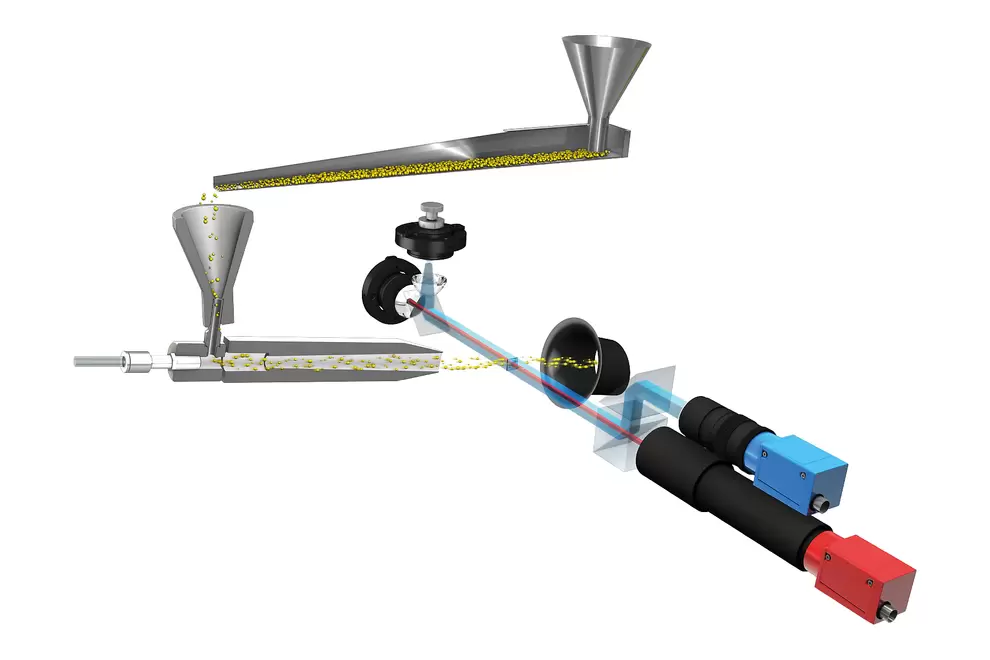

Dispersion by compressed air

The X-Jet module disperses the sample via a Venturi nozzle and is suitable for the effective analysis of powders. The actual measurement of the particles takes place in the air stream. Dispersion pressure may be set between 0 kPa and 460 kPa. This ensures optimum analysis conditions for all sample types.

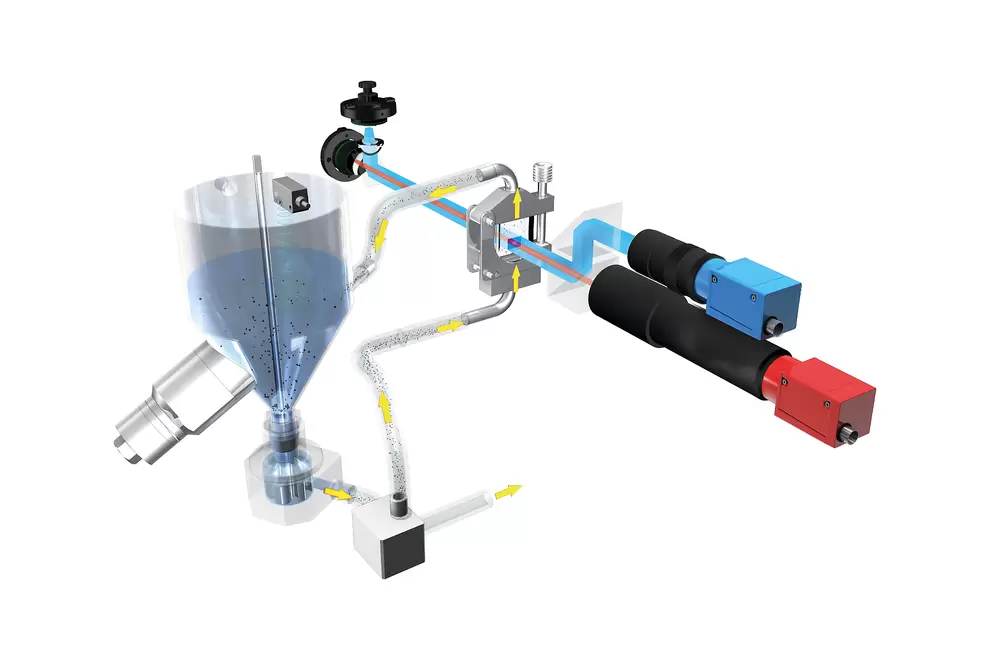

Dispersion in liquids

CAMSIZER X2 also offers the option to analyze particles in liquids with the X-Flow module. The suspension flows in a closed circle through a glass cell where the cameras record the particle images. The integrated ultrasonic unit further aids in the dispersion process.

Dispersion by gravity

The X-Fall module is used for non-destructive measurement of sensitive samples in free fall to minimize particle breakage. The sample can be recovered after the analysis.

Air Pressure Dispersion with X-Jet

Many materials tend to agglomerate due to surface forces. The X-Jet module effectively disperses the particles in an air flow while passing through a Venturi nozzle. The dispersion pressure can be set as required for individual particles. For sensitive granules, for example, reduced pressure ensures non-destructive measurement. After passing the measurement field, the sample is automatically removed from the analyzer by a vacuum cleaner.

Wet Measurement with X-Flow

The wet module X-Flow analyzes suspensions in a size range from 0.8 μm to 1 mm. The sample moves within a closed loop from the dispersion bath to the flow cell where the camera system captures the particle images. X-Flow comes with an ultrasonic bath and strong centrifugal pump to ensure efficient dispersion. Suitable dispersion media are water, alcohol, and also nonpolar organic solvents.

Gravity Dispersion with X-Fall

Flowable, unagglomerated samples can be analyzed by using the X-Fall module. The measurement is non-destructive because the particles directly fall from a chute through the field of view. X-Fall is suitable for particle sizes up to 8 mm; the detection sensitivity for over-sized grains is extremely high. In contrast to dispersion by air pressure, the sample can be recovered after the measurement with X-Fall.

Only Image Analysis Provides Information on Particle Shape

Bulk material properties like density, flowability, compactibility, conveying characteristics and surface condition are influenced by particle shape. This makes these parameters a crucial process and quality indicator in many application areas.

Examples:

- Angularity of abrasives

- Analysis of broken fractions in granules

- Detection of agglomerates in glass beads

- Analysis of the roundness of plastic or metal powder particles for Additive Manufacturing (direct influence on flowability and packing density)

- Length and diameter of needle-shaped crystals

- Analysis of the roundness of sand particles to evaluate the usability as construction material or proppant, or for geological examinations

Various parameters are available for shape quantification. These include width/length ratio (aspect ratio), circularity (calculated from area-to-perimeter ratio), symmetry, convexity, and compactness. Roundness is calculated from the curvature of the particles’ corners.

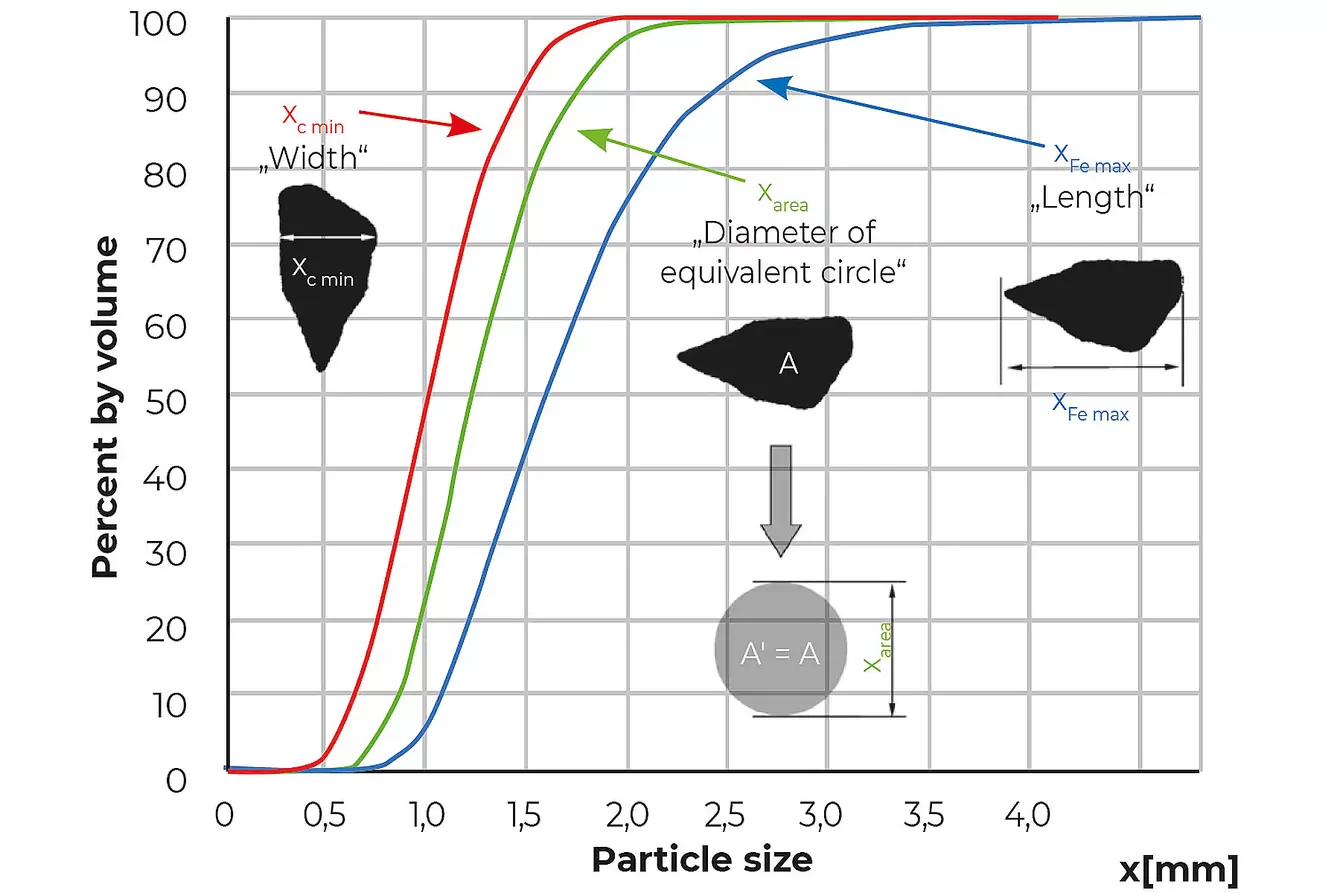

Comparability to Sieve Analysis and Laser Diffraction

„Size“ is only defined unambiguously for spherical particles: the diameter is identical in all directions and orientations. For non-spherical particles, however, the dimensions can vary strongly, depending on the orientation and direction of measurement. Traditional sieve analysis, for example, separates particles on a wire mesh sieve stack with different aperture sizes into fractions.

The smallest possible sieve aperture that a particle can pass is defined by the particle’s smallest projection area. Hence, sieve analysis measures particles in a preferential orientation and provides information which is mostly based on the width of the particle. Particle size analysis with Laser Diffraction (LD) relates all measuring data to the diameter of a spherical particle model. Only dynamic image analysis offers different size definitions which can be ascertained simultaneously. This makes the results comparable to those obtained with other techniques.

The outstanding strength of DIA is the possibility to measure width and length of a particle and to provide a size distribution based on these parameters. The particle width (red curve) can easily be compared to sieve analysis results.

Optimum configuration for each application Accessories and Options

Microtrac offers a variety of hoppers and chutes for special applications. Dispersion nozzles and cuvettes are available in different aperture sizes to ensure optimum conditions for each measurement. Calibration of the CAMSIZER X2 only takes one minute and can be carried out by using a high-precision reference reticle.

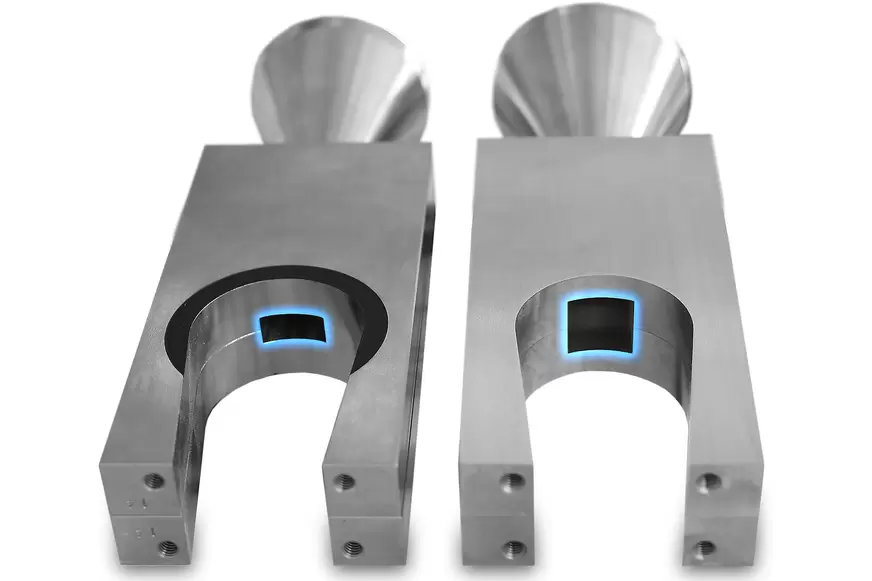

Hoppers and chutes

To achieve optimum feeding conditions, even for adhesive powders, we offer different chutes made of either stainless steel or aluminium hard-coat.

The hoppers can be made of aluminium or stainless steel and can hold up to 0,6 l of sample. The hopper is adjustable in height which promotes uniform flow of the sample.

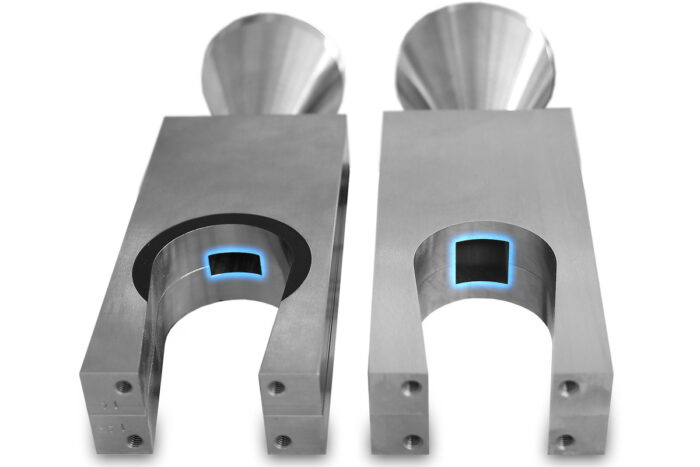

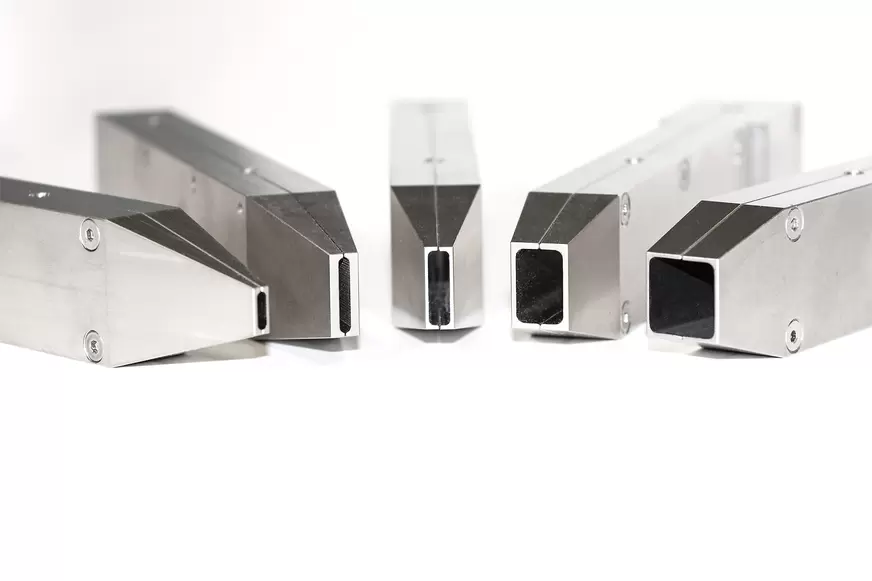

Dispersion nozzles

There are nozzle sets with different sizes of the orifice available for the X-Jet module. The standard aperture is 14 mm x 4 mm which is suitable for most samples to be analyzed. For very large or very small particles, other nozzle sizes can be advantageous.

Reference object

By using a high precision reference object made by electron lithography, which simulates differently sized particles, the CAMSIZER can be recalibrated in a few seconds at any time. This means that the requirements of modern test agent monitoring are fulfilled.

Protective hood (X-Jet, X-Fall)

The protective hood prevents the release of dust to the environment during the measurement. It can be flushed with inert gas for samples that should not be too long exposed to the ambient air. Furthermore, the hood will reduce the noise level by more than 5 dB.

Cuvettes (X-Flow)

Three high quality quartz glass cuvettes are available for the X-Flow module. The cuvettes have different gap widths of either 4 mm (standard), 2 mm or 1 mm.

Freefall shafts (X-Fall)

For the X-Fall module, the standard aperture is 7 mm x 14 mm, for larger particles a freefall unit with 14 mm x 14 mm is available.

Extended Measuring Ranges

Due to the unique two-camera principle, all measurement ranges can be analyzed in one measurement run, without any hardware adjustments.

Measurement range specifications for the diameter of compact particles:

- X-Fall (gravity dispersion)

Standard: 10 µm to 3 mm with nozzle size 7mm x 14mm

Alternative: 10 µm to 8 mm with nozzle size 14 mm x 14 mm - X-Jet (air pressure dispersion)

Standard: 0.8 µm to 1.5 mm with 4 mm nozzle

Alternative: 2 µm to 6 mm with 9 mm nozzle

Alternative: 5 µm to 8 mm with 13.5 mm nozzle - X-Flow (wet dispersion)

Standard: 0.8 µm to 1 mm2)

1) The lower limit for X-Fall depends on the sample properties (agglomeration).

For agglomerating particles the X-Jet or X-Flow module are recommended.

2) The upper size limit for X-Flow depends on the density of the sample material.

600 µm is a typical limit for materials with a density of up to 2.5 g/cm3.

Measurement range specifications for fibers and elongated particles available on request.

Typical Applications

Many properties of bulk materials, like flowability, solubility, filtration efficiency, reactivity, abrasiveness, and taste, are significantly influenced by particle size. Therefore, particle size determination is commonly used as a part of quality control in many different industries.

metal powder

- metal and ore powders

- cement

- chemicals

- activated carbon

- detergents

- construction materials

chemicals

- pharmaceutical powders / granules / fine pellets

- glass / glass beads

- plastic fibers

- plastic powders

- wood fibers

coffee

- food

- salt / sugar

- refractory materials

- abrasives

- sand

… and many more!