Features

- Fully welded stainless steel 316L internal chambers with stainless steel 304 external housingg

- Exhaust air is double-filtered through high-quality ULPA filters (per IEST-RP-CC-001.3) with typical efficiency of >99.999% for 0.1 to 0.3 micron particles, better than HEPA filters.

- An integrated pass-through with interlocking doors permits materials transfer without risk of contamination

- Single-piece, leak-tested glove assemblies which guarantee maximum protection.

Principle

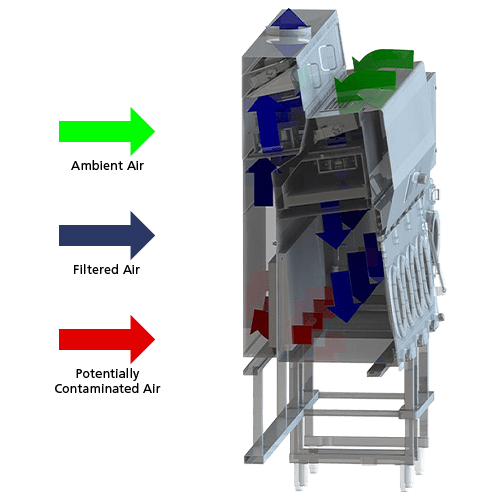

- Ambient air is pulled through the inlet prefilter located on top of the isolator. Air from the top inlet and from work zone is pulled by the fan which creates a positive pressure on the plenum that creates downflow. The HEPA (H14) downflow filter creates a laminar and particle-free ISO Class 5 air cleanliness as per ISO 14644-1 (equivalent to Class 1 as per US Fed Std 209E) inside the isolator to protect the work material inside the main chamber and pass-thru. Air from the work zone and pass-thru is quickly purged out by the fan to keep the area clean. The fan pulls approximately 90% of the purged air back to the plenum and after passing through the HEPA (H14) downflow filter.

- The high rate of airflow recirculation helps to prolong filter life and reduces the chances of ambient contaminants entering the work zone. For a recirculating model, approximately 10% of the purged air is exhausted through an HEPA-filter to prevent heat build-up inside the isolator that can be detrimental to drug compounding. This exhausted air is replenished by ambient air coming from the top inlet prefilter and a filter with 80% efficiency for positive pressure model. For a Total Exhaust/Single-Pass Model, 100% of the air is exhausted out of the isolator.

Models

| GENERAL SPECIFICATIONS Containment Barrier Isolator – Class III Biosafety Cabinet | CBI-III-2G | CBI-III-3G | CBI-III-4G | |

| Main Chamber Nominal Size (Width) | 1.2 meter (4’) | 1.6 meter (5.2’) | 2.0 m (6.6’) | |

| Working Chamber Dimensions – Min (W x D x H) | 1.2 m x 0.55 m x 0.77 m (4’ x 1.8’ x 2.6’ ) | 1.6 m x 0.55 m x 0.77 m (5.2’ x 1.8’ x 2.6’ ) | 2.0 m x 0.55 m x 0.77 (6.6’ x 1.8’ x 2.6’ ) | |

| Working Chamber Dimensions – Max (W x D x H) | 1.2 m x 0.63 m x 0.84 m (4’ x 2.1’ x 2.9’ ) | 1.6 m x 0.63 m x 0.84 m (5.2’ x 2.1’ x 2.9’ ) | 2.0 m x 0.63 m x 0.84 m (6.6’ x 2.1’ x 2.9’ ) | |

| External Dimension (with one Pass Chamber) (W x D x H) | With Adjustable Base Stand (Min) | 1.82 m x 0.92 m x 2.55 m (6.0’ x 3.0’ x 8.4’) | 2.22 m x 0.92 m x 2.55 m (7.3’ x 3.0’ x 8.4’) | 2.62 m x 0.92 m x 2.55 m (8.6’ x 3.0’ x 8.4’) |

| With Adjustable Base Stand (Max) | 1.82 m x 0.92 m x 2.85 m (6.0’ x 3.0’ x 9.4’) | 2.22 m x 0.92 m x 2.85 m (7.3’ x 3.0’ x 9.4’) | 2.62 m x 0.92 m x 2.85 m (8.6’ x 3.0’ x 9.4’) | |

| External Dimension -Small Pass-through Chamber (W x D x H) | 0.60 x 0.52 x 0.76 m | |||

| Glove Port Height (Min) | 1000 mm | 1000 mm | 1000 mm | |

| Glove Port Height (Max) | 1300 mm | 1300 mm | 1300 mm | |

| Chamber Environment | ISO Class 5 all chambers (Grade A) | |||

| Pre-filter | Process Chamber | G4, polyester media | ||

| Pass-through Chamber | G4, polyester media | |||

| Filter Type – Chamber Inlet | HEPA (H14) Filter with Integral Mesh Guard and Gasket Seal | |||

| Filter Efficiency – Chamber Inlet | 99.995% MPPS | |||

| Filter Type – Chamber Exhaust | HEPA (H14) Filter with Integral Mesh Guard and Gasket Seal | |||

| Filter Efficiency – Chamber Return and Exhaust | 99.995% MPPS | |||

| Lighting Level | ≥ 500 Lux (6000 K) | |||

| Sound Level | ≤ 80 dBA | |||

| Airflow Type | Unidirectional/ Laminar Airflow | |||

| Chamber Operating Pressure | negative 125 Pa | |||

| Isolator Construction | Chamber | SS 316L | ||

| Service Housing | SS 304 | |||

| Support Frame | SS 304 | |||

| Isolator Finish | Chamber Internal | ≤ 0.4 Ra | ||

| Chamber External | ≤ 0.6 Ra | |||

| Serivce Housing External | ≤ 0.6 Ra | |||

| Support Frame | ≤ 1.0 Ra | |||

| Electrical Requirements | 220-240 VAC, 50/60 Hz, 1Ø | CBI-3-2G8 | CBI-3-3G8 | CBI-3-4G8 |

| (by Client) | 110-120 VAC, 50/60 Hz, 1Ø | CBI-3-2G9 | CBI-3-3G9 | CBI-3-4G9 |

| Compressed Air Requirement (by Client) If no on-board compressor | 2 Bar-g Pressure at 5 L/sec | ✔ | ✔ | ✔ |

| Exhaust Duct Requirements (by Client) unless Integral Catalytic Convertor is Included | 10 “ Duct from Isolator to Outside | |||

| Air Change per Hour | 1570 ACH | 1570 ACH | 1570 ACH | |

| Volumetric Flow Rate | 916 cmh | 1225 cmh | 1532 cmh | |

| Downflow Velocity | 0.4 m/s | |||

| Net Weight | TBD | TBD | TBD | |

| Shipping Weight | TBD | TBD | TBD | |

| Shipping Dimension (W x D x H) | TBD | TBD | TBD | |

| Shipping Volume (Maximum) | TBD | TBD | TBD | |

Accessories

| LIST OF OPTIONS for CBI Models | CBI-U | CBI – T | CBI-III | CBI-H | |||

| 4″ Split Butterfly Valve (for powder discharge of powder below isolator chamber) | ✔ | ✔ | |||||

| Adjustable Hydraulic Stand (based on operator ID input) | ✔ | ✔ | ✔ | ||||

| Exhaust Box (with automated dampers with inflatable seals or manual with valve) | ✔ | ✔ | ✔ | ||||

| Anti-blow back damper box | ✔ | ✔ | ✔ | ||||

| Automated Pressure Hold Test | with Client Supplied Compressed Air | ✔ | ✔ | ✔ | ✔ | ||

| with On-board Air Compressor | ✔ | ✔ | ✔ | ✔ | |||

| Bag Welder with Table Bag-out Port | ✔ | ✔ | ✔ | ||||

| Bio Dunk Tank Bag Out Port | ✔ | ✔ | |||||

| Mobile Biodecontamination BioVap TM | ✔ | ✔ | ✔ | ||||

| Carbon Filter | ✔ | ||||||

| Convertible to Class 1 cabinet | ✔ | ||||||

| Integration of small scale aseptic or potent tablet/capsule etc… | ✔ | ✔ | ✔ | ✔ | |||

| Double-sided access | ✔ | ✔ | ✔ | ||||

| Manual Drain Ball Valve (for client controlled CIP/WP) must order with inner pass-through inflatable sealed doors. | ✔ | ✔ | |||||

| Electrical Outlet (IP66) | IP 66 | ✔ | ✔ | ✔ | ✔ | ||

| ATEX Zone 1/21 (only for internal environment) | ✔ | ✔ | ✔ | ||||

| ATEX rating up to zone 1/21 internally only (ATEX fan, “IS” signals for internal door sensor/push button) | ✔ | ✔ | |||||

| Glove Leak Tester | ✔ | ✔ | ✔ | ✔ | |||

| Formalin Vaporizer (auto neutralization and purge cycle) | ✔ | ✔ | ✔ | ||||

| H2O2 Monitoring (sensor is not integrated with HMI) | ✔ | ✔ | ✔ | ||||

| Liquid Water Entry / Exit Ports | ✔ | ✔ | |||||

| N2 Purge for Process Chamber | ✔ | ||||||

| Ø250 mm Product Waste Bag Out Ports / | ✔ | ||||||

| Battery option to maintain EM interlock during power outage or E Stop | ✔ | ✔ | ✔ | ✔ | |||

| Particle Counter | Portable Paricle Counter (Non-viable) | ✔ | ✔ | ✔ | |||

| Microbial Air Samples (Viable Particle Counter) | ✔ | ✔ | ✔ | ||||

| Product Waste Entry / Exit Ports | ✔ | ✔ | |||||

| RTPØ 105, 190, 270 – Alpha | ✔ | ✔ | ✔ | ✔ | |||

| RTPØ 105, 190, 270 – Beta Canister | ✔ | ✔ | |||||

| RTPØ 105, 190, 270 – Beta Liner | ✔ | ✔ | |||||

| RTPØ 350, 460 – Alpha, Beta Liner, Beta Canister | ✔ | ✔ | ✔ | ||||

| Service Fixtures (Vacuum, Nitrogen, Compressed Air, Nozzle for BioVap) | ✔ | ✔ | ✔ | ✔ | |||

| Spray Ball (CIP) with Manual Ball Valve | ✔ | ||||||

| Spray Gun (WIP) with Manual Ball Valve | ✔ | ✔ | |||||

| Sterile Continuous Liner | ✔ | ✔ | ✔ | ||||

| Sterility Test Pump | ✔ | ||||||

| Temperature and Relative Humidity Monitoring (only for process chamber) | ✔ | ✔ | ✔ | ✔ | |||

| Rear view monitor | ✔ | ✔ | ✔ | ✔ | |||

| UV Lamp | ✔ | ✔ | |||||

| Weighing Scale Granite Slab | ✔ | ✔ | ✔ | ||||

| Sharps (inside) | ✔ | ||||||