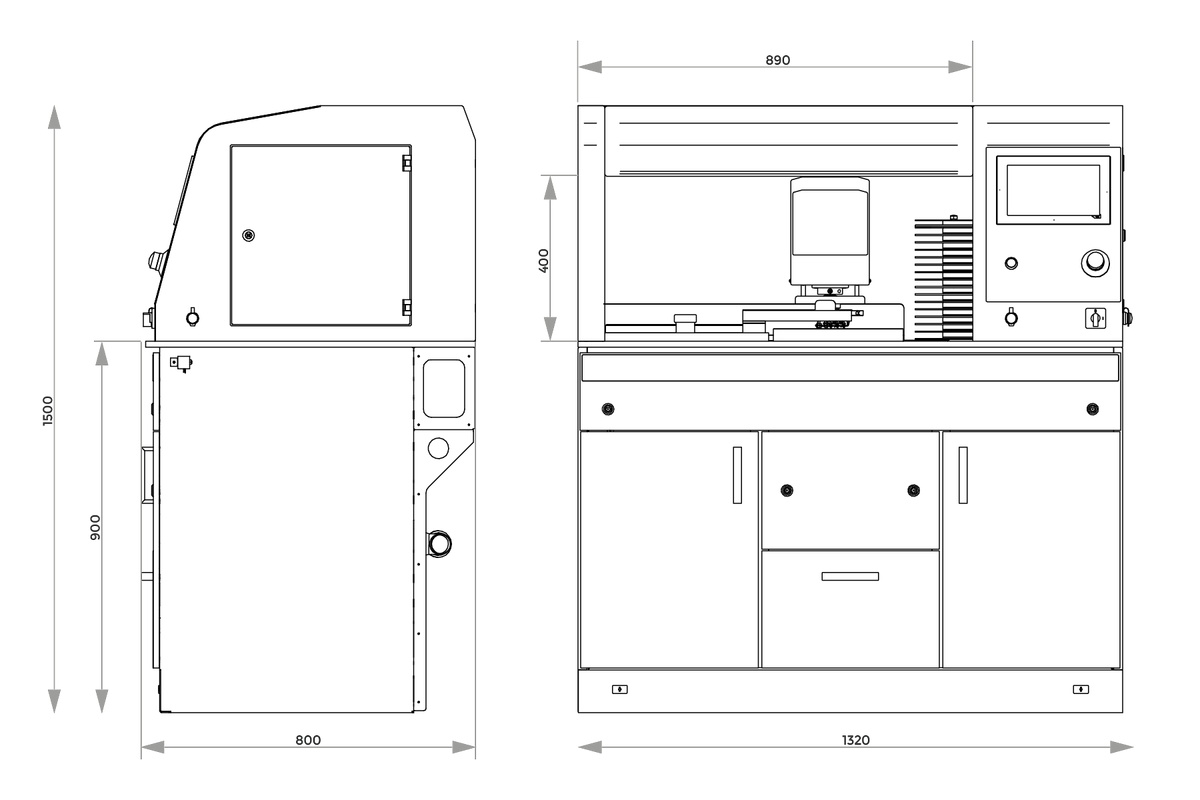

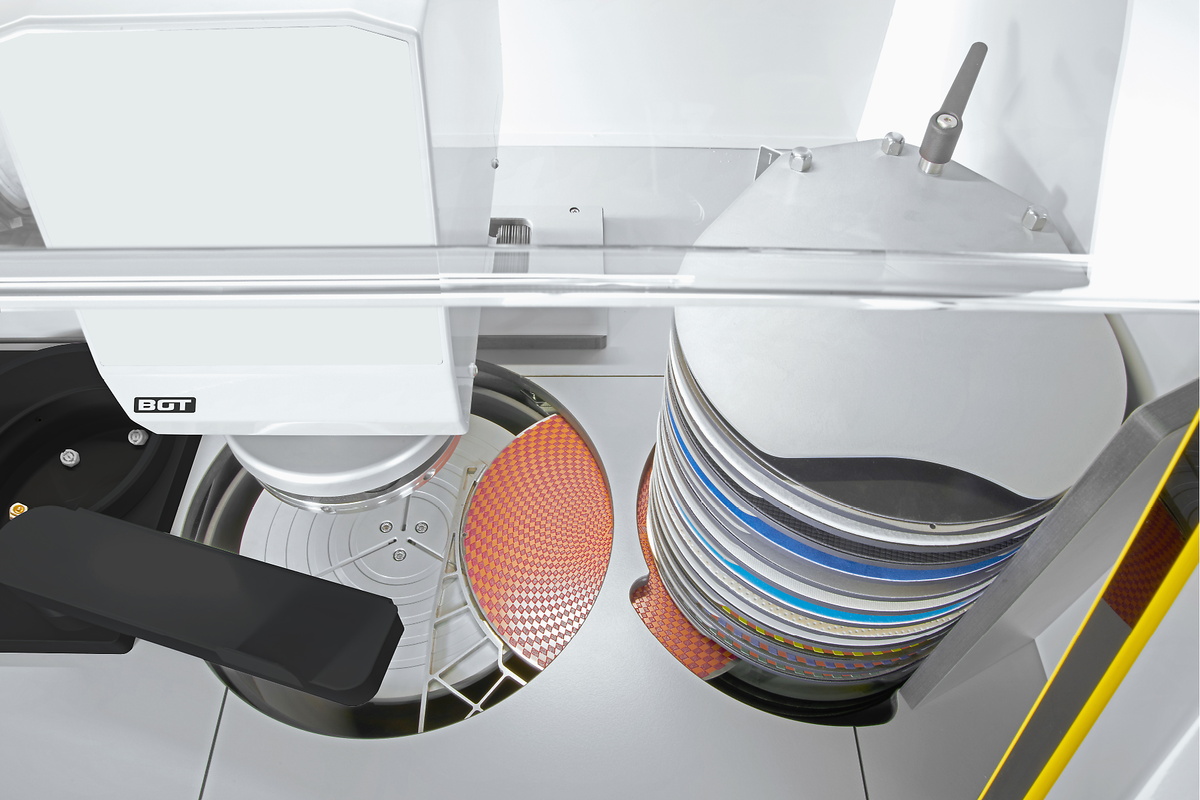

The compact fully automatic grinding and polishing robot Qpol 250 BOT combines the complete grinding and polishing process, including ultrasonic cleaning in one machine. 16x disc changer, 6x dosing unit and an integrable sedimentation tank fits perfectly into the System lab.

Intuitive user interface via touch screen and a user friendly fixation system for central force sample holder enable preparation results in shortest time. All parameters can be adjusted during the automatic process.

The benefits of automation with the Qpol 250 BOT:

- Automated Processes: Grinding, polishing, and cleaning are fully automated.

- Flexible Media Selection: Choose customized media tailored to your specific needs.

- High Reproducibility: Ensure consistent results through reliable processes.

Product Advantages

- Grinding- and polishing system with central pressure

- Aluminium case, powder-coated

- Polishing head with variable speed

- Removal measurement

- Electronic control with touch screen

- Automatic abrasive changer

- Cleaning station with water, air and ethanol

- Ultrasonic cleaner

- 6-fold dosing unit (4x diamond supension or lubriant, 2x fine polishing suspension)

- Storage drawer for abrasives

- Settling tank 45L

- Light barrier to secure danger area

Convincing benefits

Cleaning station

The cleaning station enables a fully automatic multi-step cleaning of the sample with water, air and alcohol. Cleaning times and steps are completely adjustable as needed. The ultrasonic cleaning station provides intermediate or final cleaning.

Cleaning station

The cleaning station enables a fully automatic multi-step cleaning of the sample with water, air and alcohol. Cleaning times and steps are completely adjustable as needed. The ultrasonic cleaning station provides intermediate or final cleaning.

Cleaning station

The cleaning station enables a fully automatic multi-step cleaning of the sample with water, air and alcohol. Cleaning times and steps are completely adjustable as needed. The ultrasonic cleaning station provides intermediate or final cleaning.

Cleaning station

The cleaning station enables a fully automatic multi-step cleaning of the sample with water, air and alcohol. Cleaning times and steps are completely adjustable as needed. The ultrasonic cleaning station provides intermediate or final cleaning.

This instrument is ideally suited for

geology and mineralogy applications

Perfect grinding and polishing – Consumables by QATM

Grinding and polishing is more reliable, safe and efficient when processed with the right ingredients: knowledge, care and the right choice of consumables and instruments.