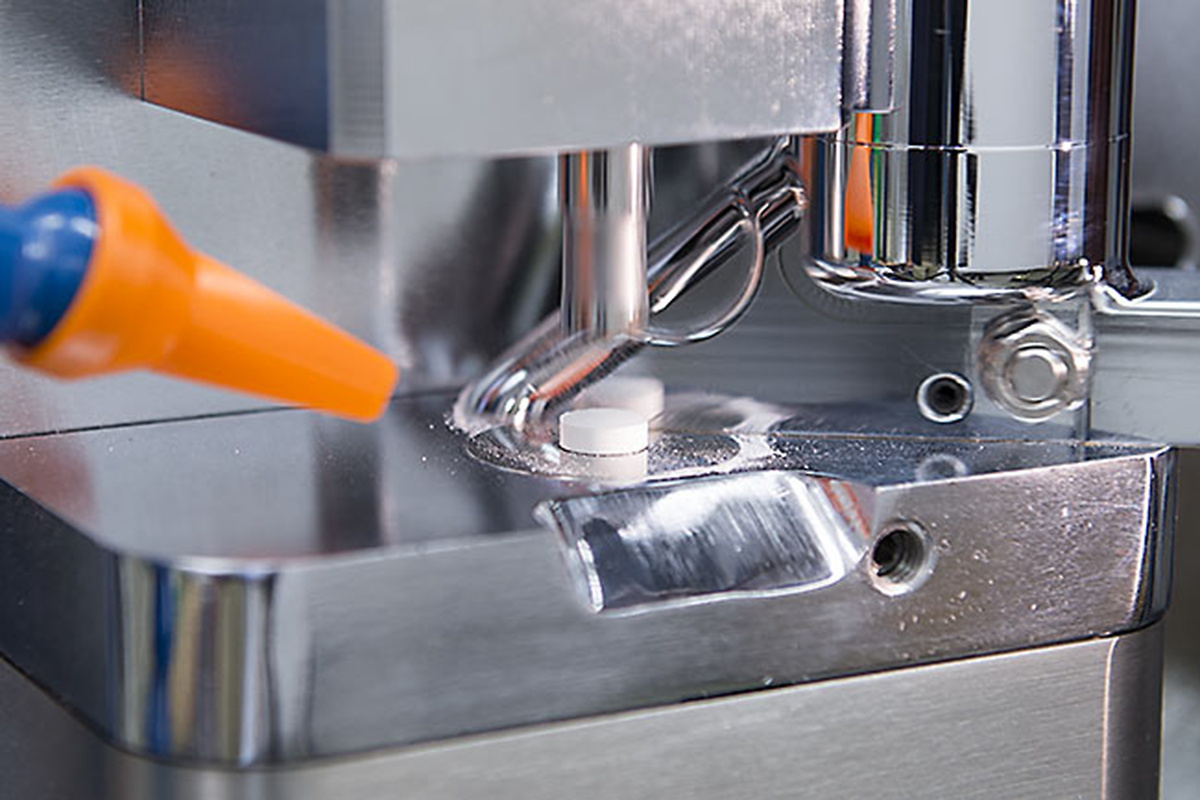

The EP-1 is the ideal desktop tablet press for R&D purposes. The single punch eccentric Tablet Press EP-1 can manufacture tablets and odd shaped products with a diameter of up to 20 mm. It operates automatically i.e. the die is filled with powder or granule, the material compressed and the tablet ejected continuously. The compression force of up to 3 tons and the filling depth of up to 17 mm are easy to adjust.

All components are either covered with hard chrome, or made of stainless steel AISI 304 or acrylic glass for the front door. Frame parts (plates) are made of 1.0332 StW22 and are bright chrome-plated. The throughput is max. 4.000 tablets per hour.

Tablet Press EP-1 Features

- Press speed infinitely variable

- Max. filling depth 17 mm

- Max. filling depth 17 mm

- Max. compression force 3 t

- Dimensions press 425/385/695 mm (L/W/H)

- Max. tablet output 4.000 tablets/hour

- Net weight 135 kg

- Dimensions with attachment parts 503/408/797 mm (L/W/H)

- Power supply 240V -15%+10%/50-60Hz

- Electrical load 2.2 kVA

Tablet Press EP-1 Options

Tailored to Your Needs

- Data transfer option

- Data logging software

- Standard data export via RS232 interface

- EP-1 single punch tablet press with compression force

- Support table in stainless steel

- Single punch and die set, 4.0 mm to 20.0 mm diameter, type STR 1, for round tablets

Technical Data

| Weight | 135 kg |

| Dimensions (H x W x D) | 695 x 385 x 425 mm |

| Dimensions (H x W x D) with attachment parts | 797 x 408 x 503 mm |

| Voltage | 200 – 240 V -15% +10% / 50-60 Hz |

| Electric voltage | 2.2 kVA |

| Protection class | I/EN 61140 |

| Protection type | IP 21/IEC 529 |

| Press speed | Infinitely variable |

| Max. tablet output | 4000 tablets/hour |

| Max tablet diameter | 20 mm |

| Max. filling depth | 17 mm |

| Max. compression force | 3 t |

| Ambient temperature during operation | + 10 °C up to +30 °C (Ambient temperature at least 5°C lower than test temperature) |

| Storage and transport temperature | +5 °C up to +40 °C |

| Relative air humidity | 25 to 80 % non-condensing |

![r-d-ep-1[1] Tablet Press EP-1](https://smarteq-sa.com/storage/2024/11/r-d-ep-11-700x700.webp)

![pic-ep-1-table-side[1] Tablet Press EP-1](https://smarteq-sa.com/storage/2024/11/pic-ep-1-table-side1-700x467.jpg)

![pic-ep-1-detail-1[1] Tablet Press EP-1](https://smarteq-sa.com/storage/2024/11/pic-ep-1-detail-11-700x467.jpg)

![pic-ep-1-detail-2[1] Tablet Press EP-1](https://smarteq-sa.com/storage/2024/11/pic-ep-1-detail-21-700x467.jpg)

![pic-ep-1-detail-3[1] Tablet Press EP-1](https://smarteq-sa.com/storage/2024/11/pic-ep-1-detail-31-700x467.jpg)

![r-d-ep-1[1] Tablet Press EP-1](https://smarteq-sa.com/storage/2024/11/r-d-ep-11-100x100.webp)

![pic-ep-1-table-side[1] Tablet Press EP-1](https://smarteq-sa.com/storage/2024/11/pic-ep-1-table-side1-100x100.jpg)

![pic-ep-1-detail-1[1] Tablet Press EP-1](https://smarteq-sa.com/storage/2024/11/pic-ep-1-detail-11-100x100.jpg)

![pic-ep-1-detail-2[1] Tablet Press EP-1](https://smarteq-sa.com/storage/2024/11/pic-ep-1-detail-21-100x100.jpg)

![pic-ep-1-detail-3[1] Tablet Press EP-1](https://smarteq-sa.com/storage/2024/11/pic-ep-1-detail-31-100x100.jpg)

![ar-403[1] All-Purpose Equipment Drive Unit AR 403](https://smarteq-sa.com/storage/2024/11/ar-4031-600x600.webp)