Vibratory polishing newly discovered

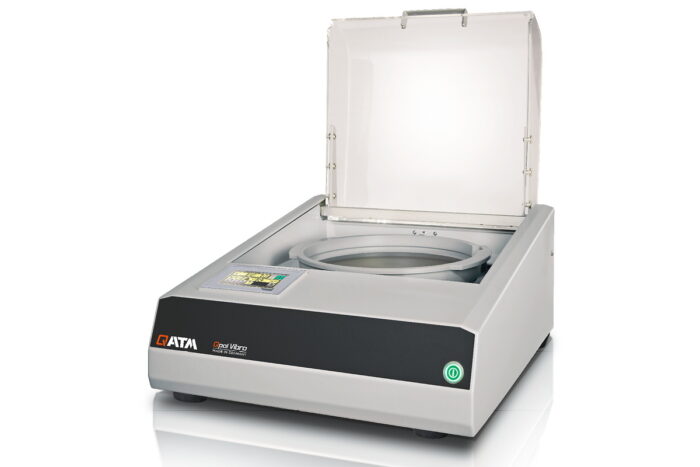

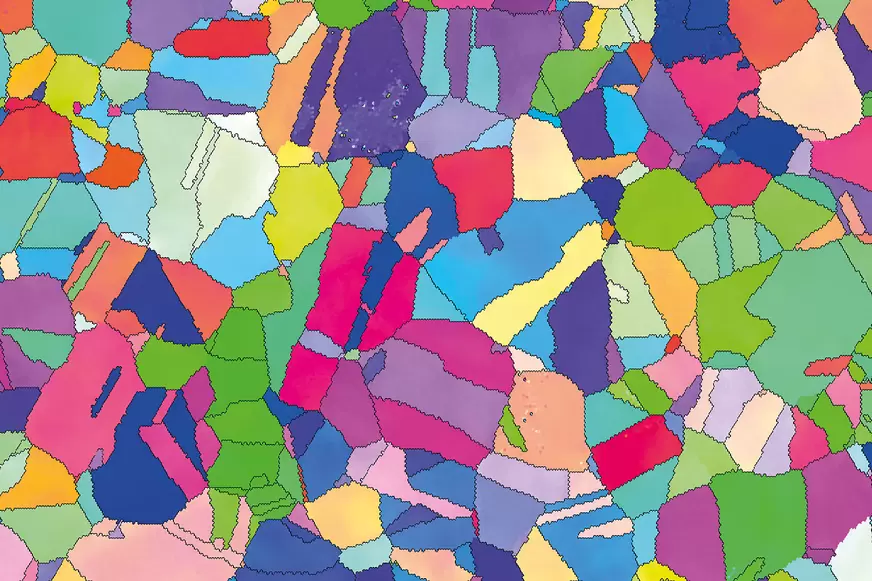

The vibratory polishing device Qpol Vibro is designed for the virtually deformation-free preparation of specimen surfaces. It is ideal for further characterizations, e.g. EBSD (electron backscatter diffraction), AFM analysis and nanoindentation or micro hardness testing.

With a diameter of Ø = 308 mm the large bowl provides sufficient space for polishing of completely filled sample holders, large specimens, as well as for simultaneously polishing up to 21 specimens. Held by strong magnets the polishing bowl can be easily removed by pressing a button and exchanged by simply putting it back into the device – the magnetic forces will do their job.

The clamping ring protects the edge of the polishing cloth to ensure a long service life. In addition, the ring delimits the polishing area and enables the sample holders to move evenly. The bowl is designed for the use of polishing cloths on magnetic systems. Consequently, the cloth is quickly and easily removed.

Product Advantages

- Rapidly exchangeable polishing bowl with magnetic system

- Automatic frequency control from 60-120 Hz

- Surface-Guard reduces crystallization of the suspension and corrosion of the specimen surface

- Pre-installed preparation methods and consumable list

- Low-noise operation and vibration-adsorbing construction

- Transparent hood made of acrylic glass with soft-closing system

- Preparation for external suction

- Memory for 200 custom preparation methods

Analysis and characterization of the prepared surfaces

EBSD-Austenite

Pattern Austenite

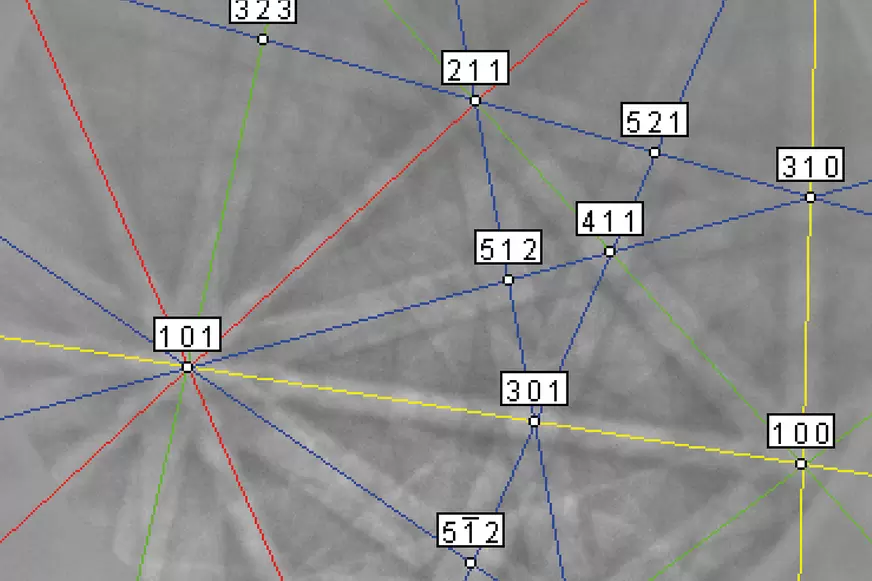

Pattern-index Austenite

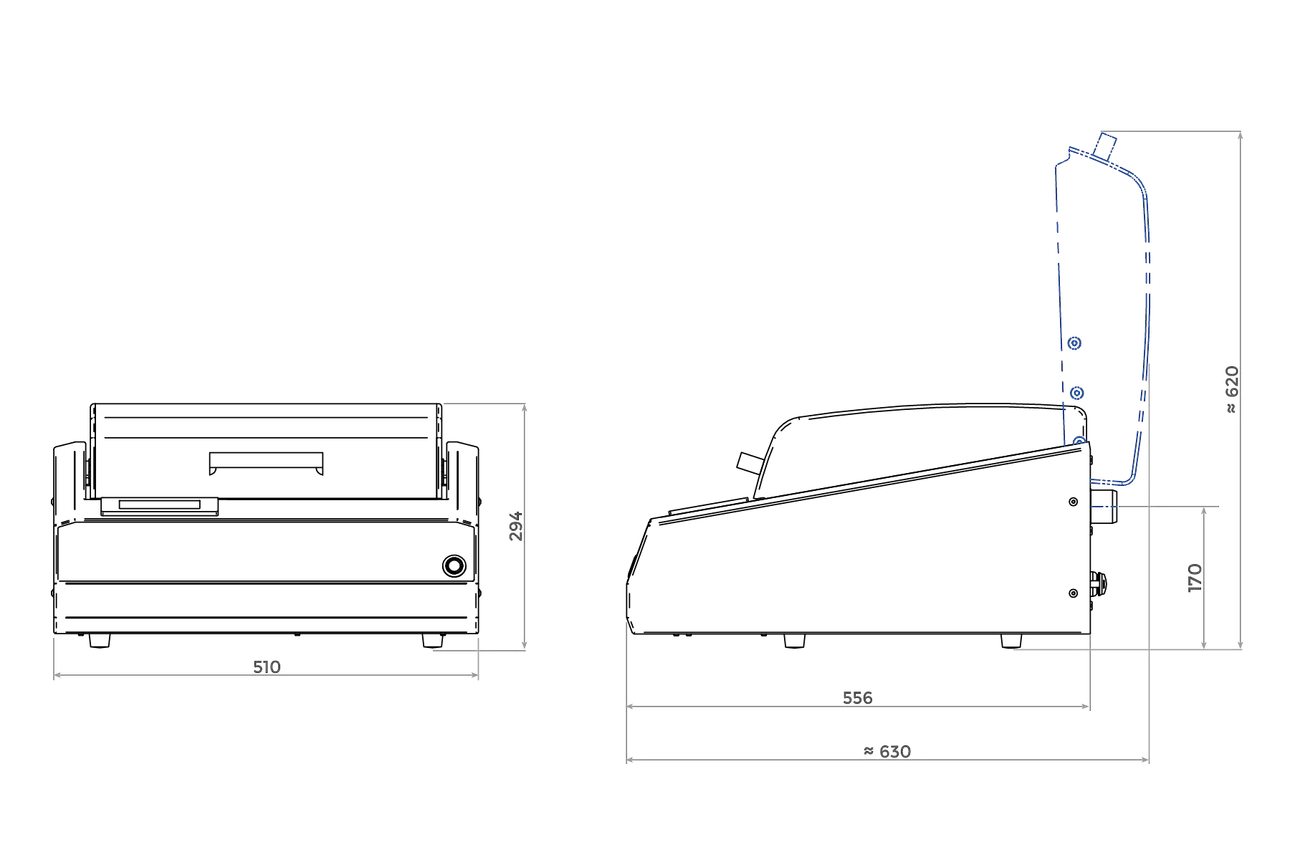

Vibratory Polisher Qpol Vibro Benefits

The Qpol Vibro offers silent operation based on its robust, high-quality design, innovative vibratory transmission angle, and vibrational motor with oscillation compensation. It may run for hours without any noticeable noise development. The oscillation compensation of the vibrational motor prevents the vibrations from being transmitted to the machine case or bench, thus ensuring silent operation of the Qpol Vibro. The exhaust connection plug may be connected to an external exhaust system to safely discharge moisture or gases, thus providing a safe working environment for the operator.

The transparent, soft-closing hinged hood shows the premium quality of QATM machines and devices. It protects the suspension and specimens from contamination for achieving best preparation results. The Qpol Vibro offers a wealth of features but is still compact and lightweight – with a weight of only 45 kg it is very suitable as a bench top device.

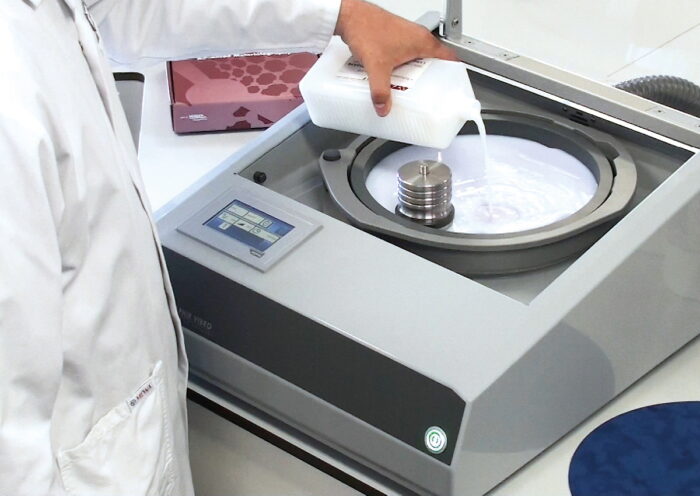

Polishing – 3 easy steps

Setting up the polishing bowl

Inserting the mounted sample

Filling in the suspension

Clear, robust design made in germany Superiority in detail

1. Exhaust connection plug

- Connection to an exhaust air system improves health and safety conditions for the operator

2. USB and Ethernet plug

- Ethernet plug for remote control and service applications; USB plug to save and exchange data

3. Exchangeable polishing bowl

- Magnetic clamping system allows fast and easy change of polishing bowl with release button, no additional tools required

- Polishing bowl with lid, if several polishing bowls are used

- QATM Surface-Guard reduces crystallization of the suspension or corrosion of the specimens after end of preparation method using automatically pulsed intervals

4. Soft-closing hood

- Best monitoring conditions due to transparent hood made of acrylic glass with soft-closing system

- Protects specimens, polishing cloth, and suspension from contamination

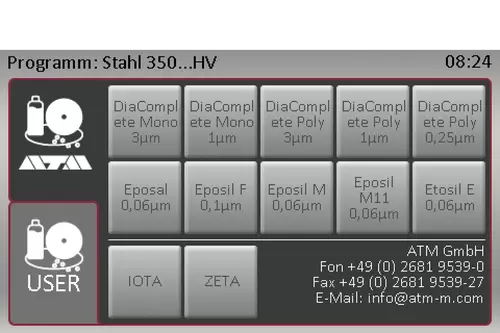

5. Touch Display

- Intuitive and easy user interface

- Pre-installed preparation methods and consumables

- Edit and save up to 200 customized preparation methods

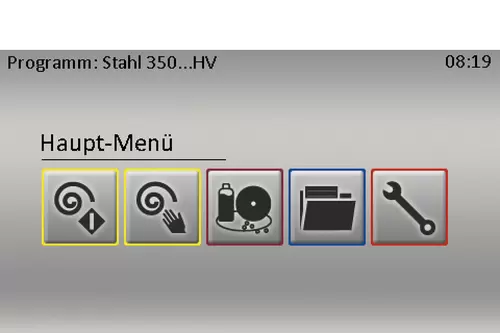

Simply clever Newly designed user interface

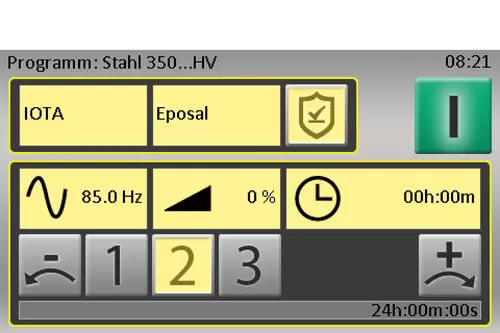

The innovative design of the Qpol Vibro software provides intuitive and user-friendly operation. 15 preparation methods for various materials are pre-installed, together with the appropriate consumables. The Qpol Vibro offers storage of up to 200 customized methods both on the device or on USB, allowing a transfer of methods from one device to another. These may be programmed without any restriction in duration or in vibration intensity. The device may be operated in manual or automatic mode. The selectively choosable alert function (timer) informs the operator that a program has ended. QATM invented a special operating mode to protect the prepared surface after preparation has finished: the Surface-Guard preserves the high quality of the prepared surface by preventing e.g. corrosion.

The Qpol Vibro is equipped with automatic frequency control which optimizes the oscillation frequency depending on the specific load of the bowl. The Qpol Vibro may be operated without supervision and almost without time-limit. This yields best polishing results and gives the user time for other tasks.

- QATM Surface-Guard

left: corrosion on specimen

right: with Surface-Guard

- Main Menu

- Automatic mode

- Menu consumables

- Menu preparation methods

For optimum results Wide selection of accessories

Sample holders

- Ø 25-25.4 mm (1”), 300 g, additional weight 90 g

- Ø 25-25.4 mm (1”), 300 g, additional weight 90 g

- Ø 38-40 mm (1 1/2”), 550 g, additional weight 190 g

- Ø 50 mm (2”), 360 g, additional weight 190 g

Levelling discs Qpol Vibro

- For levelling of mounted specimens

- Suitable for specimen with diameter 25-50 mm, 1-2”

- Special levelling discs for specimens with diameter 60 mm and 70 mm

Special sample holders

- Ø 60 mm, 875 g, additional weight 190 g

- Ø 70 mm, 605 g, additional weight 190 g

Polishing bowl

- Large bowl with Ø = 308 mm (inner diameter) for polishing non- mounted specimens, filled sample holders, and for simultaneous polishing of up to 21 specimens

- Fast and easy changing of the bowl due to release button and magnetic system

- Strong hold of bowl by magnetic forces

- Especially designed for all polishing cloths with magnetic system

- Lid protects polishing cloth from contamination

Polishing cloths

- Iota, Ø 300 mm (long flocked, soft synthetic cloth)

- Zeta, Ø 300 mm (short flocked, soft synthetic cloth)

- Further polishing cloths Ø300 mm available

Suspensions

- Eposal

- Eposil F, Eposil M

- Eposil Non Dry

- Etosil E

Vibratory Polisher Qpol Vibro Tips & Tricks

- For recurring polishing processes of different materials, simply use a different polishing bowl for each material.

- Additional weights should be used for hard specimen materials or low mass materials. The number of weights depends on the material hardness and the specimen size.

- How to improve your preparation?

Start directly after the last step of QATM’s standard preparation methods and choose one of the polishing methods for a particular material pre- installed in the Qpol Vibro. - We recommend to first grind and polish your specimens, e.g. according to the QATM standardized preparation methods. Vibratory polishing is the next step in the process.

Vibratory polishing methods

| Material | Suspension | Cloth | Frequency | Time (h) | Additional weights |

|---|---|---|---|---|---|

| Steel 50…150HV | Eposal | IOTA | 85 | 02:00 | 1-2 |

| Steel 150…350HV | Eposal | IOTA | 85 | 01:30 | 1-2 |

| Steel 350…HV | Eposal | IOTA | 85 | 01:00 | 2-3 |

| Cast iron | Eposal | IOTA | 85 | 02:00 | 2-3 |

| Austenitic steel | Eposal | IOTA | 90 | 02:00 | 2 |

| Aluminum & alloys | Eposil M | IOTA | 90 | 01:30 | 1 |

| Copper & alloys | Eposil M | IOTA | 90 | 01:00 | 1 |

| Titanium & alloys | Eposil M11 | IOTA | 90 | 02:00 | 1-2 |

| Superalloys | Eposil M11 | IOTA | 90 | 06:00 | 2 |

| Lead alloys | Eposil M | IOTA | 85 | 03:00 | 1 |

| Glass | Eposal | IOTA | 90 | 06:00 | 2 |

| Ceramic | Eposil M | IOTA | 90 | 06:00 | 2-3 |

| Minerals | Eposal | IOTA | 90 | 06:00 | 2 |

| Rocks | Eposal | IOTA | 90 | 06:00 | 2 |

| Cleaning mode | Water & soap 50:50 | IOTA | 90 | 00:10 | 0 |

Perfect grinding and polishing – Consumables by QATM

Grinding and polishing is more reliable, safe and efficient when processed with the right ingredients: knowledge, care and the right choice of consumables and instruments.