The Qcut 150 A is a flexible precision cut-off machine which is used with cut-off wheels up to a diameter of 203 mm/8”.

The compact benchtop model performs automatic as well as manual cuts with the ergonomic lever. The optional sample holder arm with built-in force sensor ensures low-deformation cuts due to a precise force-controlled feed rate.

Product Advantages

- Up to 5 different modes: manual, automatic feed, force-controlled feed, grinding mode, cutting with table attachment (depending on machine configuration)

- Manual cross feed

- Zone cutting function

- 4 different cooling systems availabe

- Dressing device

- Intuitive QATM software with integrated database

This instrument is ideally suited for

geology and mineralogy applications

Precision cut-off machine Qcut 150 A Features

Force-controlled cutting

- Integrated force sensor in the sample holder arm precisely regulates the feed rate via the set cutting force

- Constant cutting force throughout the process for clean cutting even of edge-hardened components and composite materials

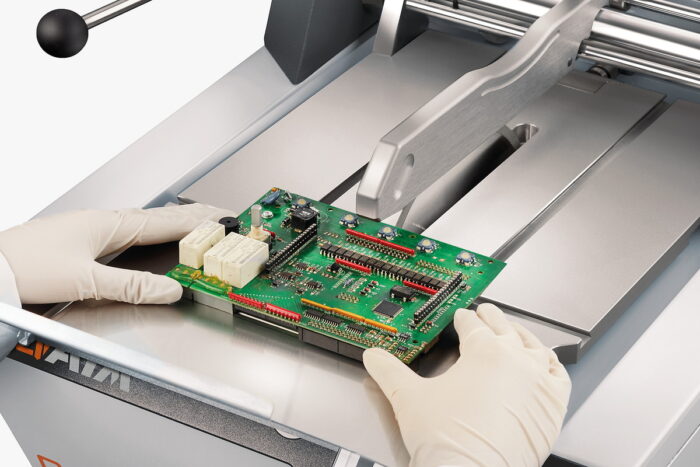

Table attachment

- Table attachment can be mounted without tools

- Quick and manual sectioning of large samples, PCBs, or plate material

NEW: Zone-cutting

- Individual adjustment of feed rate or cutting force for single sections of the sample

- Reduced material deformation and heating

- Accelerated cutting process

All parameters at a glance

- Robust 4.3″ industrial touchscreen

- Intuitive software with modern interface displaying all important cutting parameters

- Extensive program storage and user account control

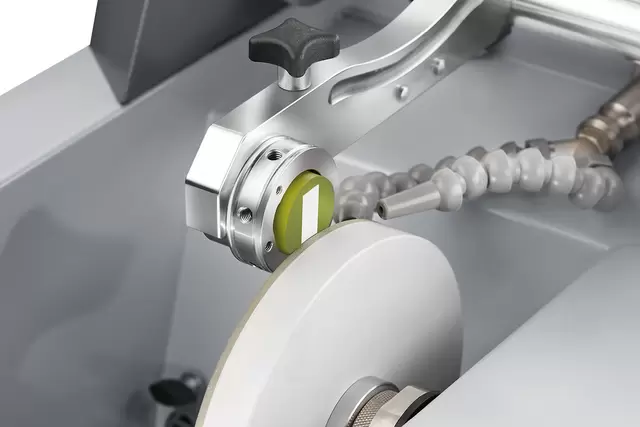

Grinding mode

- Target preparation: In grinding mode, samples can be ground manually or semi-automatically using a cup wheel

- Ideal for thin sections and microelectronics

Vacuum clamping unit

- Glass slides for thin sections can be fixed easily and without slipping

Reduces subsequent grinding processes

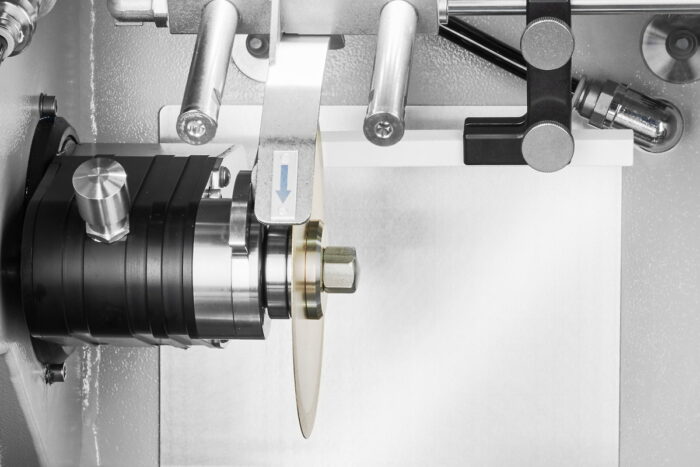

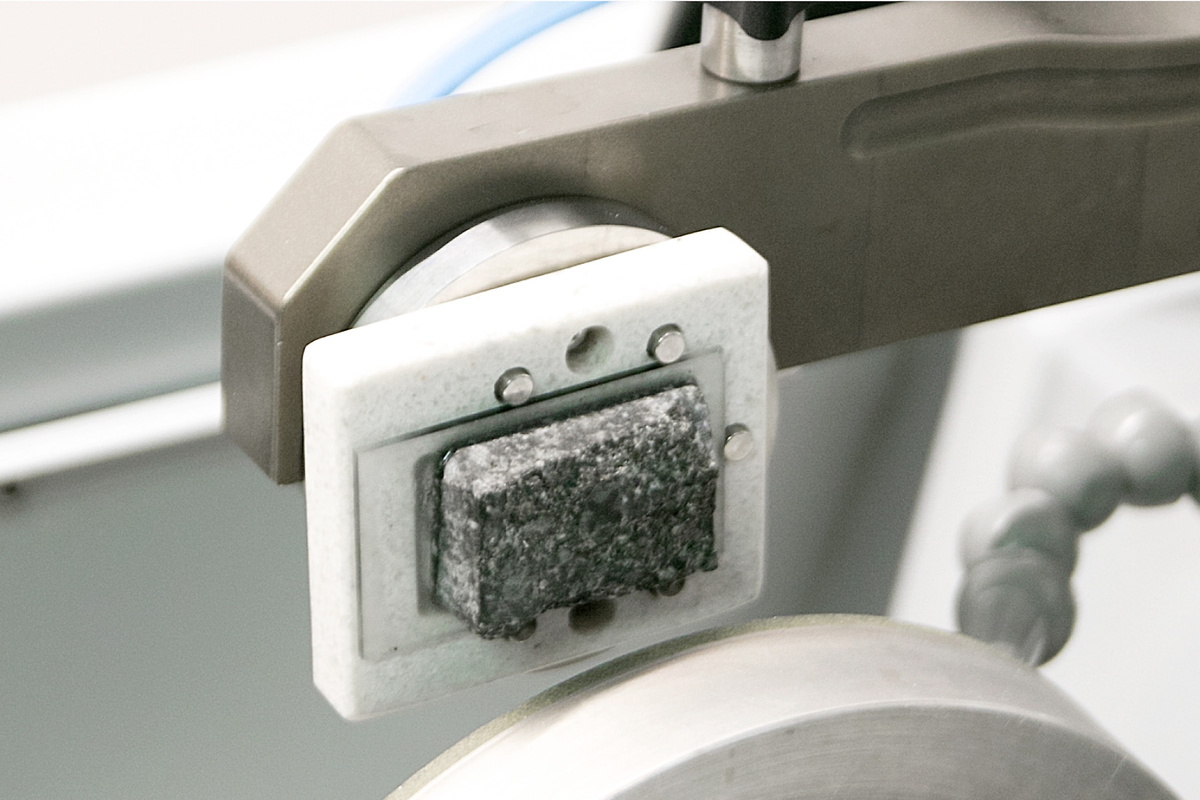

The use of the adaptive rotation axis leads to an even more uniform cutting pattern and reduces the risk of the cut-off wheel runout. This reduces the effort required for later plane-parallel grinding of the sample.

Superiority in detail

1. Sample holder arm

- Tool-free quick-clamping system for mounting :

- Precision clamping devices

- Rotation device

- Vacuum clamping unit

- Max. sample size: Ø 40 mm

2. Y-axis

- Manual or automatic feed

- Travel: 120 mm

- Feed rate: 0.01–20 mm/s (automatic)

- Cutting force variably adjustable: 0–10 N (optional)

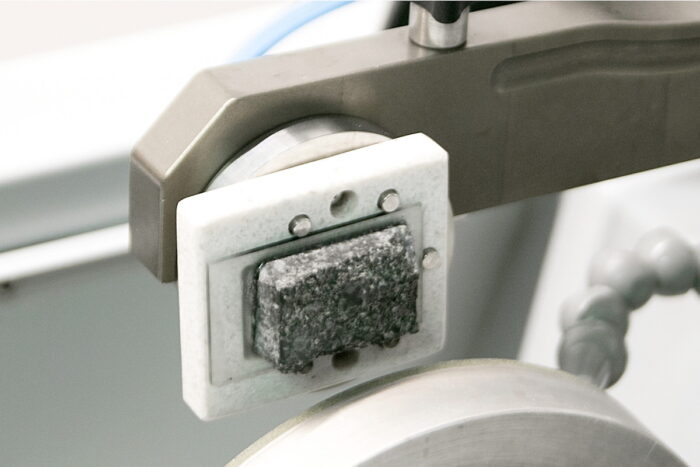

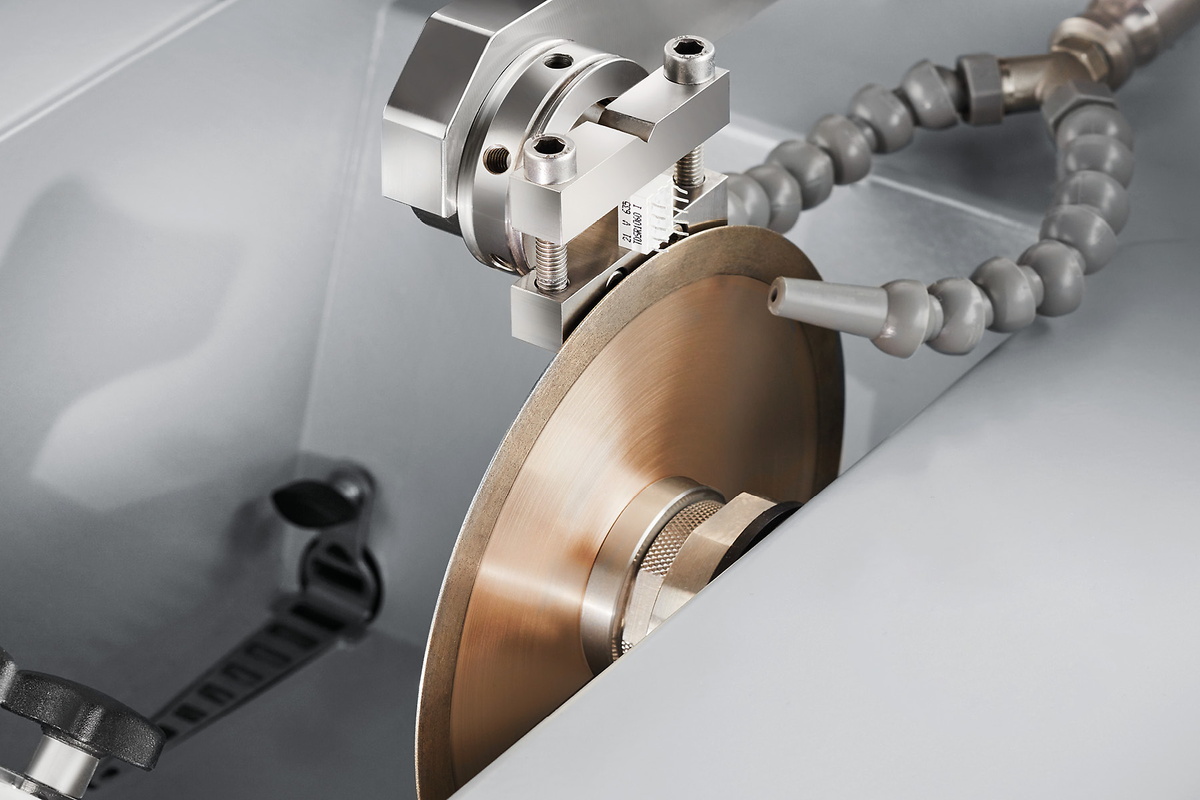

3. Dressing device

- For sharpening diamond cutting and grinding wheels

- Can be operated manually from the outside

4. Robust machine body

- Sturdy and corrosion-resistant stainless steel housing

- Powder-coated, for easier cleaning

5. Transparent hood

- Swivel hood with free access to the cutting chamber

- Integrated safety switch

6. Z-axis

- Manual cross feed

- Travel: 25 mm

- Position shown on the display

- Positioning accuracy: 0.005 mm

7. Cut-off Wheel drive

- Cut-off wheel size: Ø 75–203 mm / 8″

- Drive power: 0.37 kW (S1)

8. Ergonomic Control panel

- 4.3″ industrial touchscreen

- Intuitive interface displaying process data

- Storage of up to 200 user-defined cutting methods

- User account management

Extensive range of clamping tools

With the help of a suitable clamping tool from the extensive range of accessories, mounted or non-mounted samples up to a size of Ø 40 mm can be clamped in the cut-off machine comfortably

Optimal accessories for Qcut 150 A and 200 A Recirculation cooling systems

Optimal cooling is essential during sectioning. Excessive heat generation during the sectioning process damages the specimen and increases the wear of the cut-off wheel. The cooling and corrosion protection agent dissipates the heat and simultaneously removes the chips from the cut-off chamber.

15L Recirculation cooling system

- Portable system with filter cartridge and lid

- Small footprint required

- Easy to integrate into existing laboratory furniture

- Two-chamber system for filtration

45L Recirculation cooling system (Mobile)

- Mobile unit with inlet strainer, filter bag and overflow

- Can be placed under a lab bench or floor-to-ceiling cabinet

- Expandable with optional pump module for cut-off chamber flushing

- Two-chamber system for filtration with removable separating slide

45L Recirculation cooling system (System lab)

- Mobile unit with retractable mechanism

- Can be conveniently integrated into QATM system laboratory cabinets and cabinets with undershelves

- Expandable with optional pump module for cut-off chamber flushing

- Inlet strainer, filter bag and overflow

- Two-chamber system for filtration with removable separating slide

Perfect cutting – Cut-off wheels from QATM

Cutting is more reliable, safe and efficient when processed with the right ingredients: knowledge, care and the right choice of consumables and instruments. The Qprep range includes specially developed cut-off wheels for a wide variety of materials and requirements.

- Low thermal influence on the specimen during the cutting process

- Wet abrasive cutting achieves very fine surface finishes after cutting

- Optimal cutting shortens the further preparation process

Fast, Powerful, Flexible – Qtool Clamping devices

Our innovative clamping devices are used to clamp workpieces securely and precisely to ensure exact cutting and grinding processes. There is a wide range of different clamping devices that have been developed for specific applications and workpiece sizes.

- Suitable for regular and irregularly shaped samples

- Fast, repeat-accurate clamping of regularly shaped samples

- Large range of different clamping tools and systems available