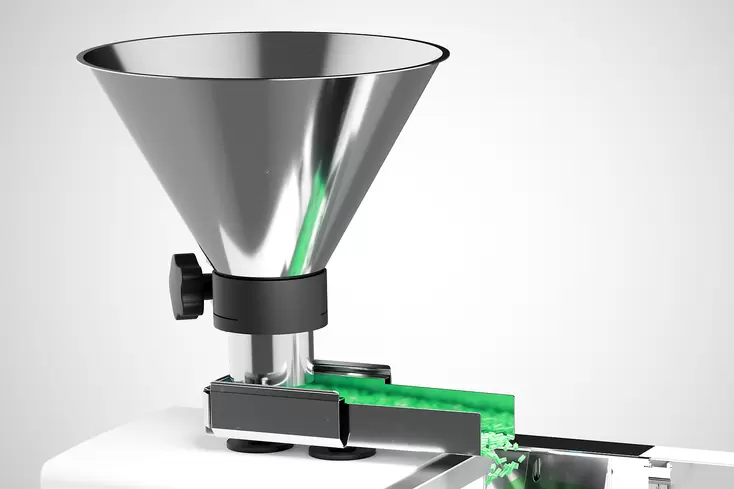

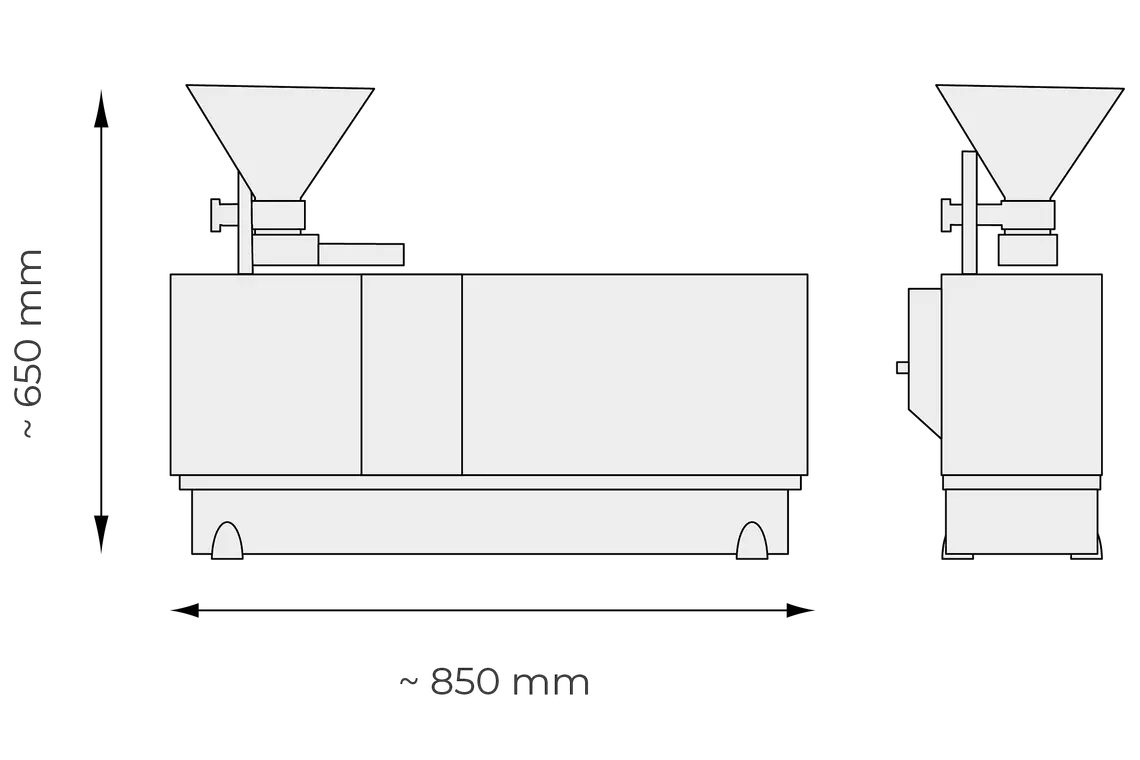

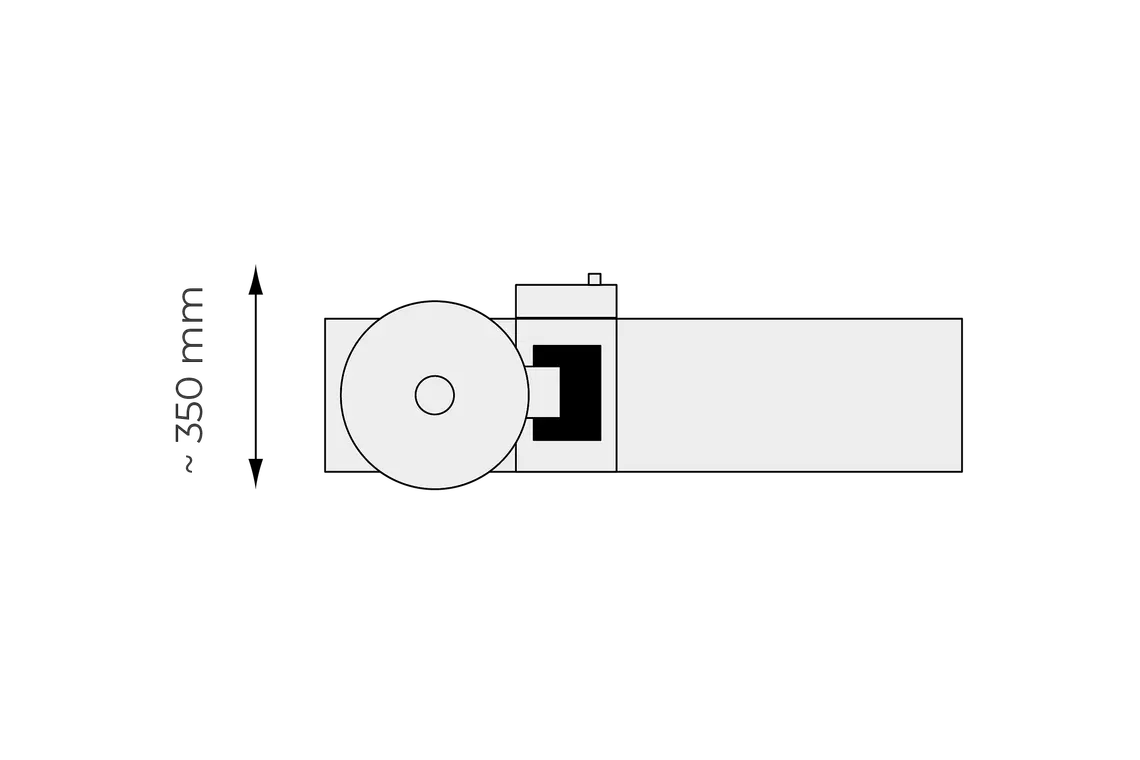

With its focus on the essentials of dynamic image analysis, the CAMSIZER S1 is purpose-built for basic quality control applications. This streamlined approach results in a system that is not only more efficient but also easier to use.

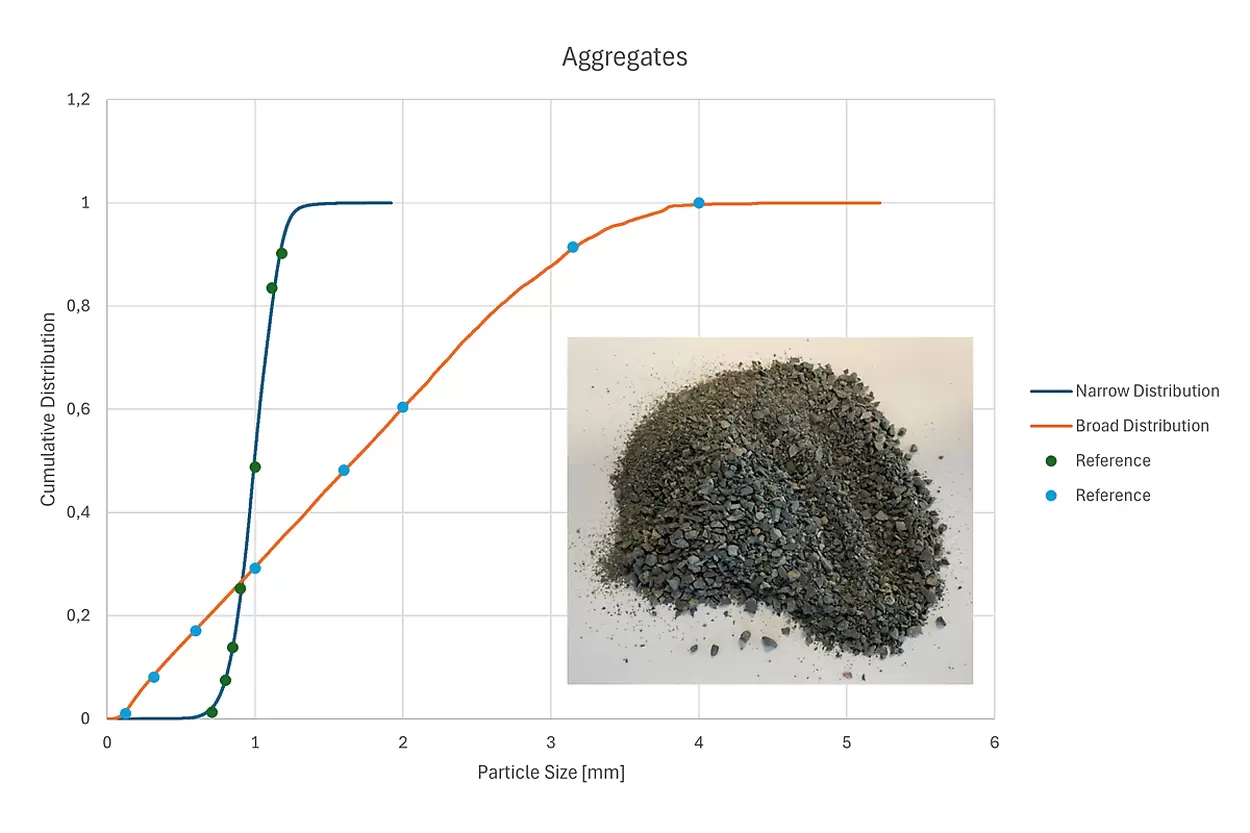

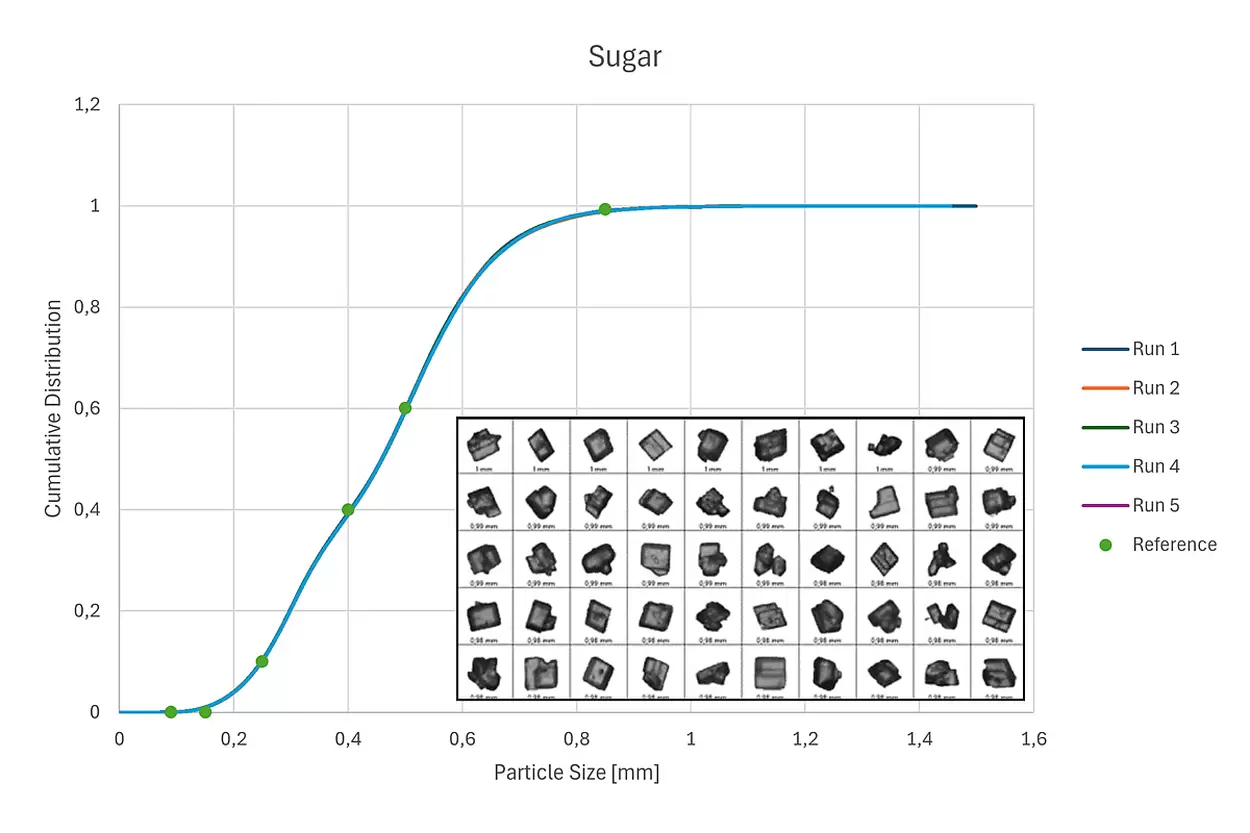

Users can expect a seamless experience, from sample preparation through to final analysis, making the CAMSIZER S1 the most efficient choice for laboratories and production facilities seeking to enhance their quality control processes without the complexity of more advanced systems. The CAMSIZER S1 can handle a vast variety of applications, with excellent repeatability and correlation to traditional sieve analysis. Simultaneously, it delivers basic particle shape information. The CAMSIZER 3D and CAMSIZER S1 are two devices that look almost identical from the outside but are suitable for different applications and levels of complexity. While the CAMSIZER S1 is a cost effective entry-level device with a focus on quality control of standard applications, the CAMSIZER 3D is designed more for sophisticated shape analysis and applications in research and development.

Particle Size and Shape Analyzer CAMSIZER S1 Focusing on the Essentials

- High-Quality Imaging: Equipped with a 12 Megapixel camera for detailed particle analysis

- Broad Particle Size Range: Capable of analyzing particle sizes from 30 microns to 5 millimeters.

- Fast Measurement: High-speed analysis with a large field of view, providing results in just 2-5 minutes.

- High Sample Throughput: Achieve up to 30 measurements per hour thanks to quick operation and easy sample preparation.

- Automated Measurements: Standardized measurement routines ensure consistent quality control.

- Highest Resolution: Precise results with detailed images.

- Ease of Use: Simple connectivity with just two USB ports is required; no dedicated PC or cumbersome hardware installation is needed.

- Efficiency: Designed for standard requirements in the bulk solids laboratory without compromising on performance.

- Over 25 Years of Expertise: Microtrac’s legacy of competence and innovation in dynamic image analysis

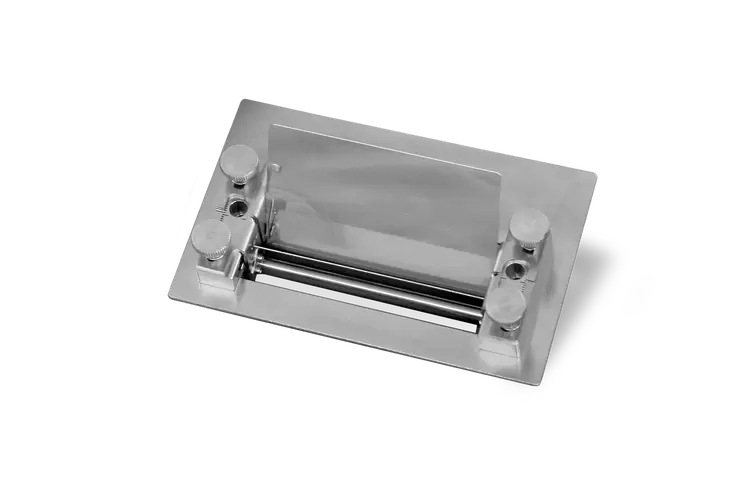

Accessories and Options

Typical Applications

Many properties of bulk materials, like flowability, solubility, filtration efficiency, reactivity, abrasiveness, and taste, are significantly influenced by particle size. Therefore, particle size determination is commonly used as a part of quality control in many different industries.

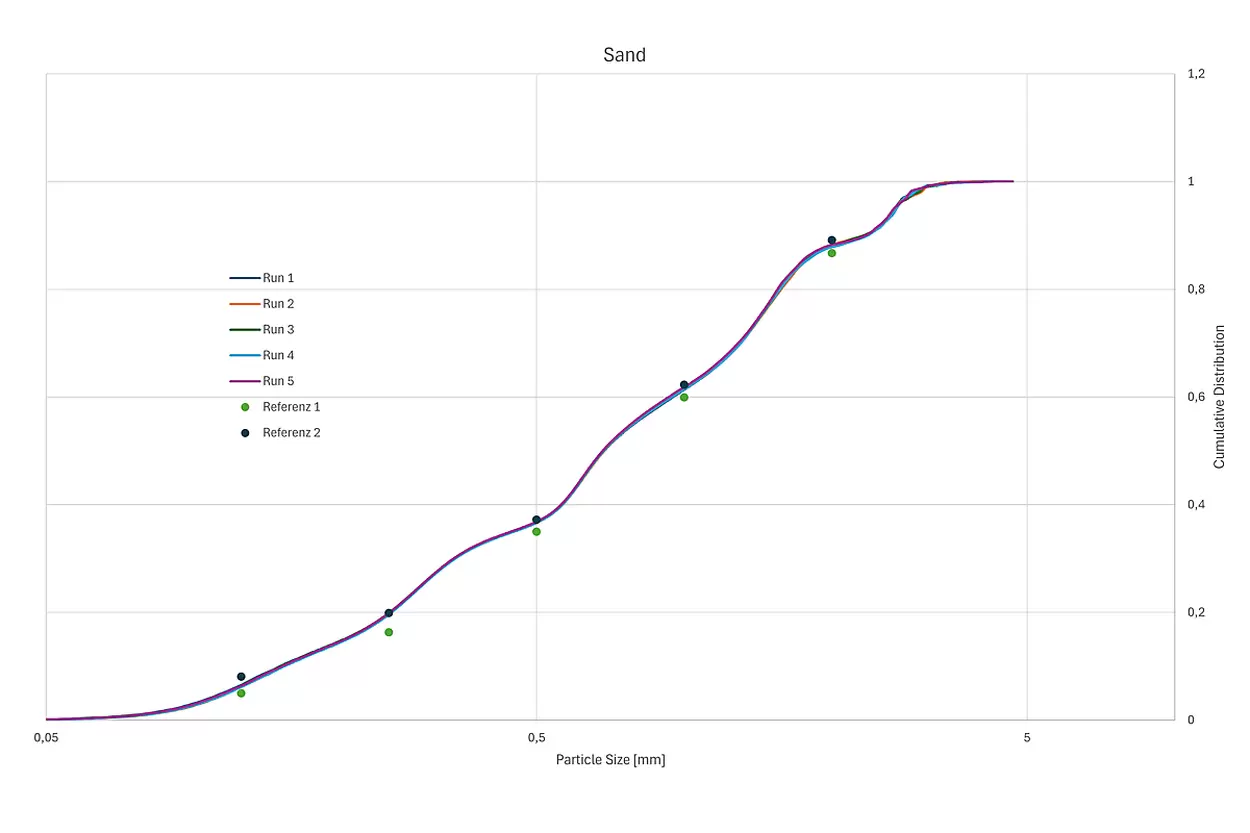

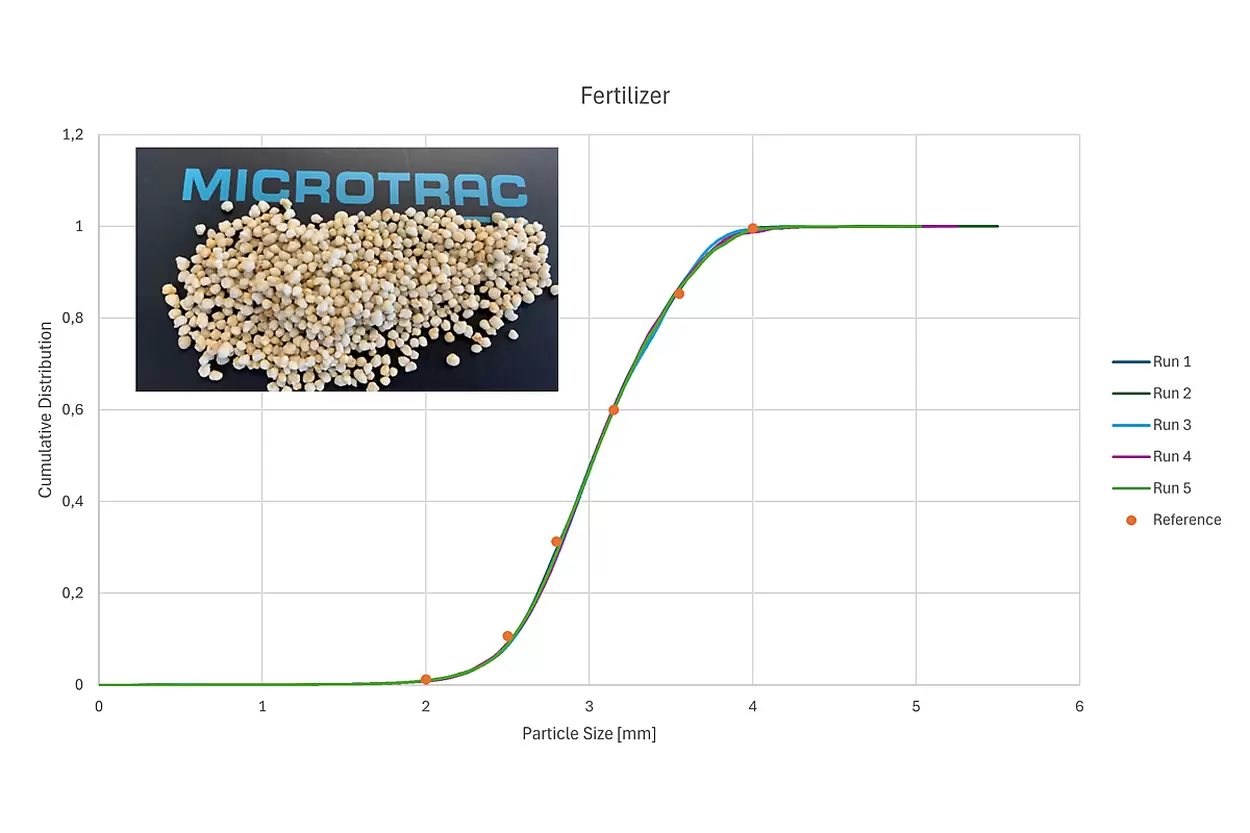

The CAMSIZER S1 provides important measurement data within a few minutes that determines the quality of the sample. The results are consistent with traditional sieve analysis, which means that established product specifications do not need to be changed. Due to the high level of automation, measurement errors are virtually impossible, with significantly higher sample throughput. Another advantage is that shape analysis provides additional information about the sample that is not accessible with sieve analysis.

sand

- sand and sediments from coarse silt to fine gravel

- sugar

- abrasives and blasting media

- seed, coated and uncoated

fertilizers

- glass beads

- foodstuffs

- Expandable Polystyrene

- superabsorbents

sugar

- salts

- fertilizers

- pharmaceutical pellets / granulates

… and many more!