The Qcut 350 A is an automatic wet abrasive cut-off machine for samples up to max. Ø 135 mm. Due to its low contact cutting (lcc) function, it gently cuts different types of samples with various geometries, sizes and materials.

The cut-off machine is commonly used in metallography, materialography, mineralogy, as well as for the cutting of composite materials (CFC/PMC/MMC) or electronic devices such as PCB’s.

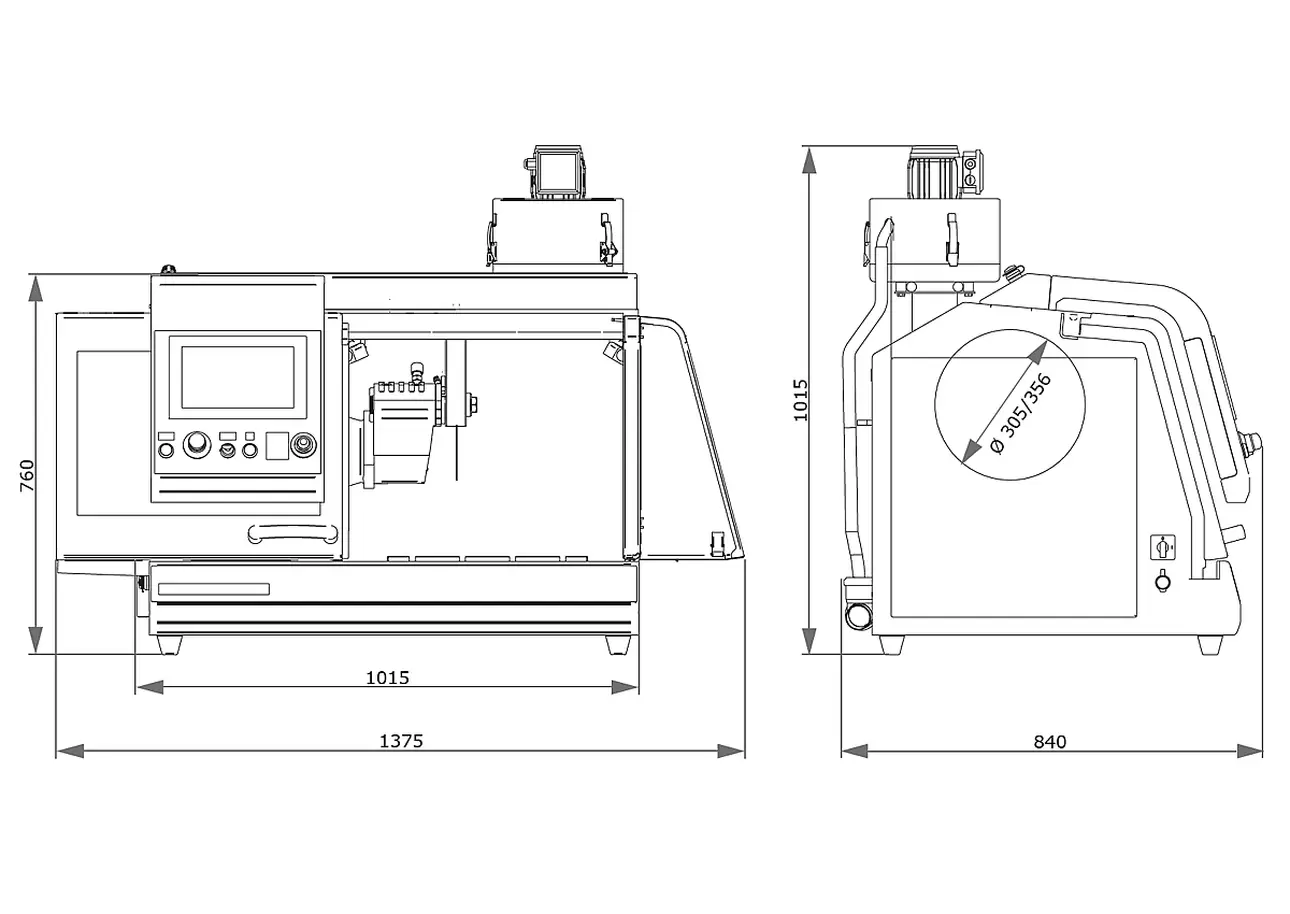

The large cutting chamber and stainless steel table of the machine allow comfortable and flexible operation. A wealth of software based features, such as automatic touch detection, multi-position process and parallel setting of the wheel guard during vertical cutting further enhance the reproducibility of cutting processes.

Product Advantages

- Automatic horizontal movement

- Automatic vertical movement

- Electronic control of cutting force

- Electronic control of distance

- Electronic cutting force limiter

- Memory for saving programs

- Large range of different clamping tools and systems available

- Opening on the right for long parts

Features

Electronic performance control

The feed rate is reduced upon reaching the preset maximum power. This protects the machine and its cutting components from overloading.

Precision cross feed

The optional, automatic cross-feed with series cut function is suitable for exact parallel cuts. Operational handling takes place via electronic control. The electronic cross-feed can also be applied as feeder axis when working with pot wheel.

Pulsed cutting

In cases where there are heavy sections and materials which are difficult to cut, the variable pulsed cutting system gives decisive advantages.

Multi-Position-Process MPP

With the “Multi-Position-Process” (MPP) you can place multiple specimens on the table and cut them in one sequence. The teach-in function enables a simple and user-friendly setting of various cutting positions.

Automatic touch detection

After automatic start of the cutting process the sample is approached in rapid run. By touching the cut-off wheel the sample is cut efficiently and safely with preset cutting parameters.

New dimensions

The enlarged cutting chamber and worktable combined with parallel setting of wheel guard increases cutting capacity and travel for all axes. The side door ensures optimum access to the cutting chamber and the additional opening for supplying long sample parts opens up much possibilities.

Electronic control

Cutting parameters for the automatic traverse cuts can be saved in the electronic control, and then loaded later. The position of the manual traverse cut is also shown on the display. All parameters such as feed rate, travel and cutting force can be altered during automatic cycles.

Perfect cutting – Cut-off wheels from QATM

Cutting is more reliable, safe and efficient when processed with the right ingredients: knowledge, care and the right choice of consumables and instruments. The Qprep range includes specially developed cut-off wheels for a wide variety of materials and requirements.

- Low thermal influence on the specimen during the cutting process

- Wet abrasive cutting achieves very fine surface finishes after cutting

- Optimal cutting shortens the further preparation process

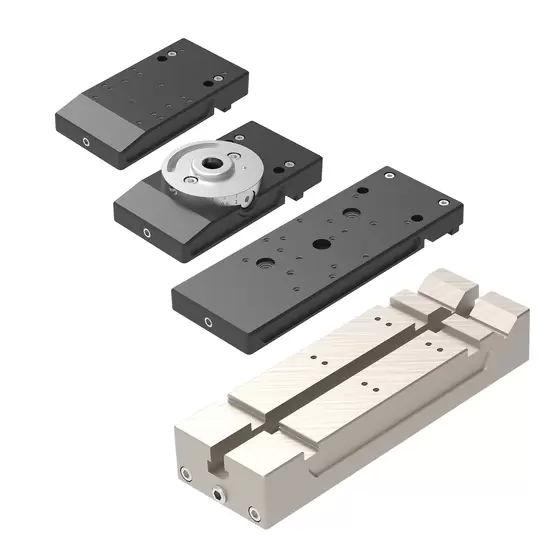

Fast, Powerful, Flexible – Qtool Clamping devices

Our innovative clamping devices are used to clamp workpieces securely and precisely to ensure exact cutting and grinding processes. There is a wide range of different clamping devices that have been developed for specific applications and workpiece sizes.

- Suitable for regular and irregularly shaped samples

- Fast, repeat-accurate clamping of regularly shaped samples

- Large range of different clamping tools and systems available