Cutting in 5 dimensions – the Qcut 600 BOT is a fully automatic cut-off robot. Equipped with patented cutting- edge technology, it opens up new possibilities in the cutting process for materialographic sample preparation.

- Patented technology: Complex cutting sequences can be performed using 5-axis technology (X, Y, Z, B, C axes) without time-consuming re-clamping of the workpiece.

- Highest degree of automation: Dynamic cut-off wheel measurement and automatic adjustment of cutting parameters. Multiple cuts on different workpieces can be made in one process.

- High reproducibility: Repeatable cutting operations are easy to program and perform.

- Multi-Position Process (MPP): Simultaneous positioning and automatic cutting of different components on the machine table.

Cutting Robot Qcut 600 BOT Superiority in detail

1. Ergonomic control panel

- Large 12.1″ industrial touchscreen with intuitive QATM software

- Quick setup, control of all axes with two joysticks

- The sliding control panel enables unobstructed working conditions

2. Robust machine body

- Sturdy powder-coated steel construction

- Integrable recirculating cooling unit

- Automatic central lubrication of the axes

3. Large round machine table

- Made of stainless steel with integrated longitudinal and cross T-slots

- Secure clamping of complex workpiece shapes using the T-slot table or Easy clamping system

- Diameter: Ø 600 mm

- Load capacity: up to 150 kg

- Travel: X: 550 mm, Y: 360 mm, Z: 550 mm

4. Large cutting chamber

- Large sliding door provides easy access and visibility

- Side swing door for convenient access to cutting chamber

- Large side door for easy cut-off wheel replacement

- Break-resistant LED interior lighting

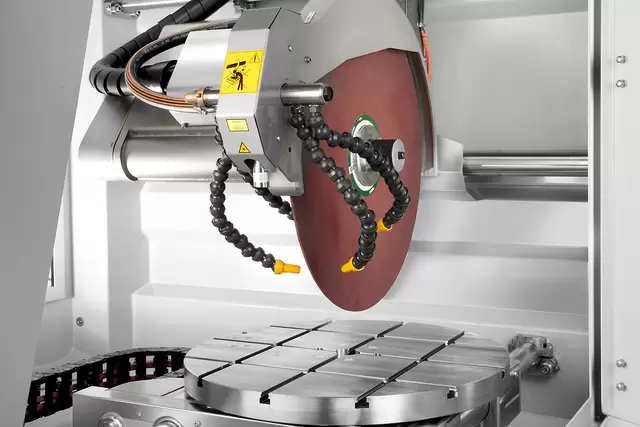

5. Optimized swivel arm

- Highly efficient cooling system

- Increased cutting capacity thanks to parallel guided cut-off wheel guard

- Laser alignment aid for easy workpiece positioning

6. Rotation axis, B-axis

- Rotation range 360°, with combined C-axis 200°

- Positioning accuracy: ±0.1°

7. Optional rotation axis, C-axis

- Rotation range: max. 360°

- Removable modular rotation axis

- Clamping capabilities can be expanded with a lathe chuck or other clamping devices

Free accessibility For large workpieces

Large workpieces can be placed directly on the machine table by a forklift or crane via the wide sliding door.

In 5 dimensions, sectioning the small from the large

With the patented 5-axis technology, workpieces can be cut at any angle precisely, repeatably, quickly, and easily. All axes are finely adjustable and remain vibration-free during the cut-off process – precise work is easier than ever. The positioning capabilites/movement of the various axes in combination with the clamping systems enables precise cutting of the workpiece without time-consuming re-clamping of the workpiece. All necessary cut-offs can be performed sequentially and automatically – even with large workpieces.

1. Y-AXIS (Chop cut)

- Cutting range: 360 mm, automatic

- Rapid traverse up to 80 mm/s.

2. Z-AXIS (Cross feed)

- Travel: 550 mm, automatic

- Cross feed for precise parallel cuts in series

3. B-AXIS (Rotation axis)

- Rotation range: max. 360°, with combined C-axis 200°, automatic

- Positioning accuracy: ±0.1°

4. X-AXIS (Travel cut)

- Cutting range: 550 mm, automatic

- Rapid traverse up to 80 mm/s.

5. C-AXIS (Rotation axis)

- Rotation range: max. 360°, automatic

- Removeable modular rotation axis

Cutting Robot Qcut 600 BOT Features

Stainless steel rotary table

Spacious rotary table (Ø 600 mm) enables precise work even under heavy loads.

- Rotation of the machine table (max. 360°) eliminates the need for time-consuming re-clamping of workpieces

- Can be expanded with a modular adaptable rotation axis (C-axis)

- Integrated T-slots for the Easy clamping system for quick mounting of clamping tools

Automatic cut-off wheel measurement

Dynamic cut-off wheel measurement leads to reproducible cutting results with consistent quality.

- Automatic monitoring of the current cut-off wheel diameter

- Adjustment of cutting parameters after each cut

- Enables consistent cutting speed and cutting depth

Robust machine with large cutting chamber

Robust, powder-coated steel machine body with large sliding door made of scratch-resistant laminated safety glass and large side door.

- Machine body with integrable recirculating cooling unit and automatic central lubrication

- Optimal access to the large cutting chamber with safety interlock that prevents door opening when the cut-off wheel is operating

- Large side door for easy cut-off wheel replacement

Cutting Optimization

To optimize the cutting quality, the machine automatically detects local material characteristics, such as hardened areas.

- Cutting force-dependent feed control

- Cut detection: When starting a new cut, the workpiece is automatically detected and approached at reduced speed

- Parallel-guided cut-off wheel guard increases the cutting capacity of the cut-off wheel during chop cuts

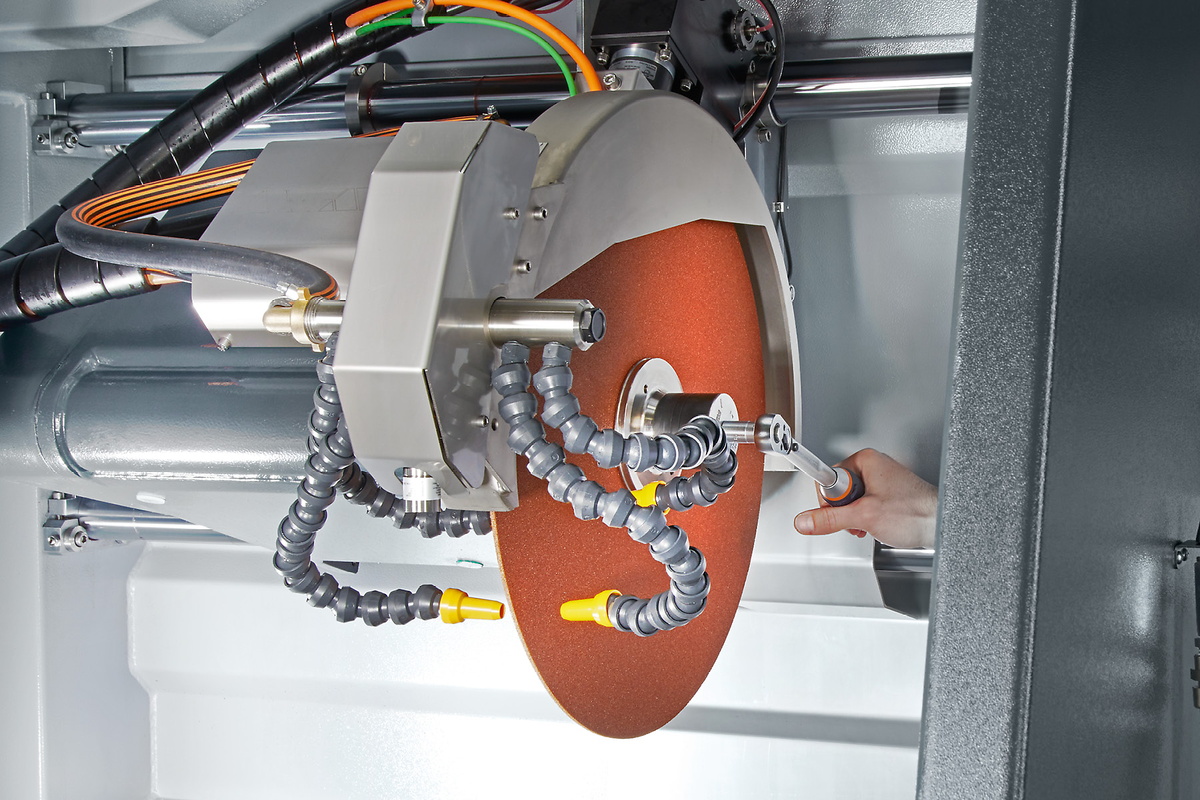

Powerful cut-off wheel drive

Precise swivel arm guidance and cut-off wheel cooling.

- Water-cooled main drive with 15 kW drive power

- Optimal cooling thanks to flexibly adjustable cooling hoses

- Parallel guided cut-off wheel guard for increased cutting capacity when making cross cuts

Intuitive and easy operation

Large 12.1″ industrial touchscreen with intuitive QATM user software, joysticks, and emergency stop switch.

- The teach function enables user-friendly programming of cutting positions by manually positioning the machine at each desired location

- Simultaneous positioning and automatic cutting of different workpieces without re-clamping (Multi-Position Process MPP

Clever design

Easy cut-off wheel replacement and simple clamping allow you to focus on cutting.

- Laser alignment for easy workpiece positioning

- Power clamping nut: easy clamping and loosening of the cut-off wheel

Maximum ease of use

The control panel is movable and can be freely positioned for ergonomic operation during setup and operation of the machine.

- Programming in close proximity to the workpiece

- During series operation, the control panel can be moved to the side

Cut-off machine Qcut 600 A Accessories

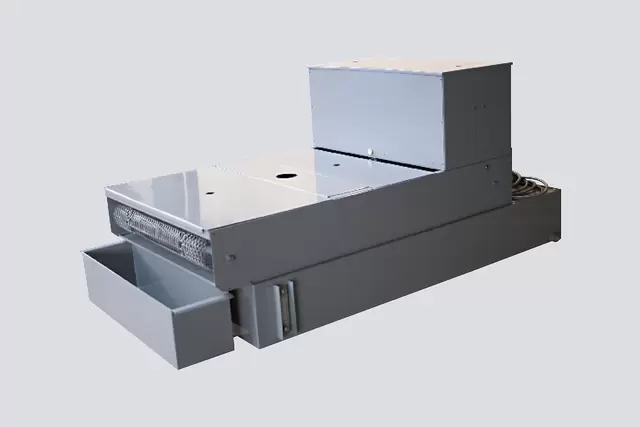

Recirculation cooling unit

Compact, integrable cooling system for standard applications.

- Can be integrated into the housing and extended

- Multi-chamber filtration

- Inlet sieve with filter bag (see consumables)

Belt filter system

Large cooling and filter system for continuous operation, e.g. in serial applications.

- Tank size: 285 l

- Filtering capacity: 100 l/min (referring emulsion)

- Pump capacity: 100 l/min

Centrifugal Separator

Work safety: Working environment with improved air quality.

- Removes coolant mist

- Purifies the air and increases visibility

- Exhaust power 452 or 500 m3/h depending on voltage