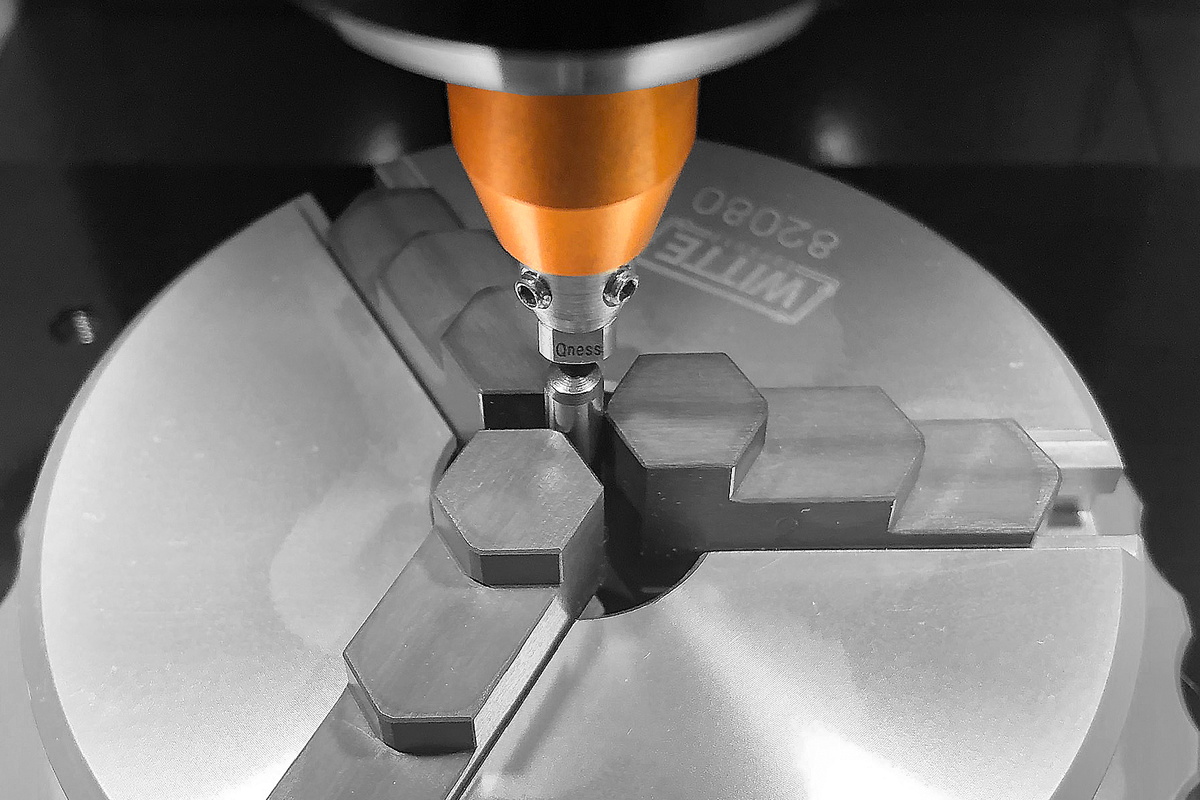

The Vickers / Knoop / Brinell / Rockwell hardness tester series Qness 10 / 60 takes micro hardness testing to a whole new level: The high-end laboratory devices of the latest generation combine the best of both worlds – hardness testing and microscopy without compromise and with maximum operating convenience. The revolutionary optical system with color camera provides reproducible and reliable results every time.

The classic “Qness 10 / 60 M” model of this Vickers / Knoop / Brinell / Rockwell hardness tester promises perfect semi-automatic operation and high precise positioning control of the Z axis. The combination of micro hardness tester and microscope makes this entry-level model a convincing solution for the laboratory.

QATM micro hardness testers seamlessly integrate with the Verder Scientific IoT platform, featuring remote real-time monitoring, live notifications, effortless backups and automatic software updates.

Qness 10 / 60 M Product Advantages

- Semi-automated

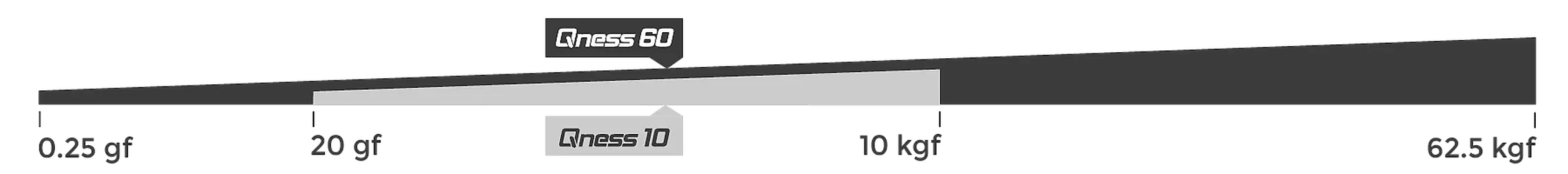

- Wide test force range (0.25 g – 62.5 kg)

- Ready to Test package, includes: ASTM+DAkkS certified Vickers diamond, 5x / 50x lenses

- Dynamic test turret with 8-position tool changer

- Qpix Control2 M Software including INSPECT microscopy features

- Digital XY cross slide with data feedback

- Controlled automatic Z axis

Qness 10 / 60 M Experience the 3D model in the real world!

AR-Model – Visit the page with your smartphone or scan the QR code under “View in Room” and experience the 3D model in the real world!

Qness 10 / 60 M Test Methods & Force Range

QATM hardness testers accurately analyze according to all standard test methods and cover a wide spectrum.

The electronically controlled, fully automated test cycles ensure fast, precise hardness testing, as well as fast method changes and automatic detection of the focal plane. With the Ready to Test package all Vickers test methods are possible with the standard scope of delivery.

Integrated conversions

DIN EN ISO 18265, DIN EN ISO 50150, ASTM E-140

Qness 60 M/A+/ all Vickers test methods possible with standard scope of delivery

✓ Qness 10 M/A+ with standard scope of delivery HV0.02 to HV10 possible.

* not according to standards

Qness 10 / 60 M Microscopy & Analysis with Qpix Inspect

Phase Analysis

DIN 9042, ASTM E-562

- Automatic image object dimensioning

- Provides analysis results as percentage proportions of a surface or as nominal surface values as tables or diagrams

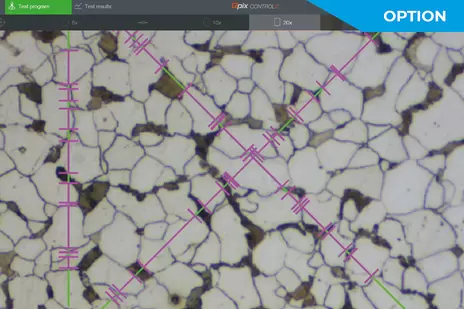

Particle Size Determination

DIN 9042, ASTM E-562

- Particle size determined via linear or circular section method

- Results of the analysis provided as tables or diagrams

- Abrams Circles, Heyn Lines, Snyder-Graff Line

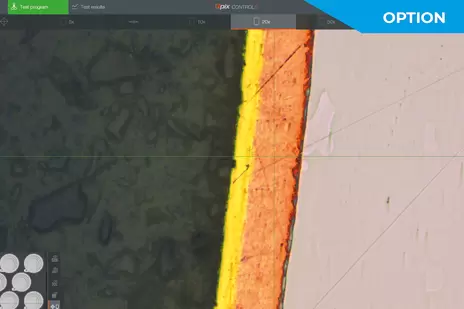

Layer Thickness Measurement

DIN EN ISO 1463

- Determination of layer thickness

- Semi-automated gauging of horizontal, vertical and radial layers.

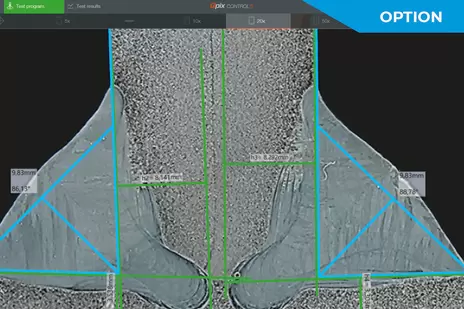

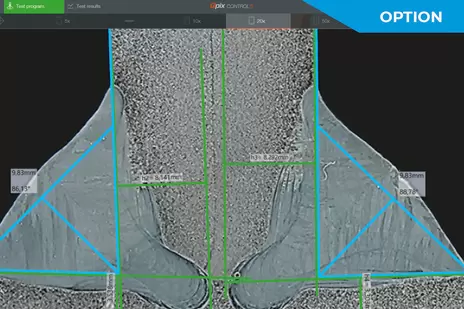

Weld Seam Measurement

DIN EN ISO 5817

- Standardised measurement and evaluation of weld seams

- Prefabricated templates with all relevant measuring tools such as throat thickness, weld reinforcement, penetration depth, etc.

- Automatic good/bad evaluation and report generation

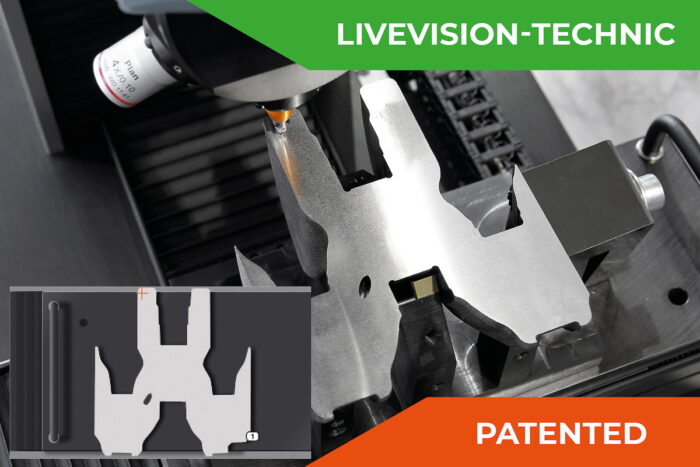

Qness 10 / 60 M Revolutionary optic system

The QATM-developed, in-house manufactured lens system sets new standards. As well as providing crystal clear image quality for hardness testing, Koehler illumination uses white LED light and motor-operated aperture shuttering to produce ideal contrast, even for high magnification images.

Experienced metallurgists agree the image quality provided by the Qness 10 / 60 M is comparable in all aspects with that of established sophisticated microscopes. The up-to-date concept and new lenses in the optic system enable the device to completely meet even the strictest physical ‘test system definition’ requirements in compliance with DIN EN ISO6507-1/2:2018.

Qness 10 / 60 M Innovative Operation

Test space lightning

All devices are equipped with the new LED work space lighting: Simplified positioning of samples for single-piece tests.

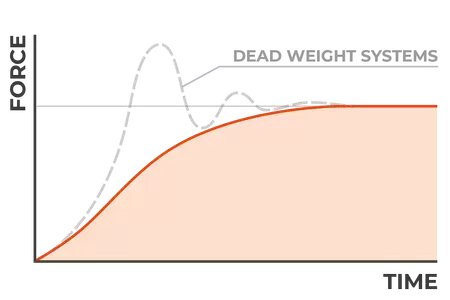

Vertical concept with 2 Z-axes

There are decisive benefits in distributing vertical movement across 2 axes. Via the first Z-axis there is dynamic motion control, allowing the indenter to be positioned towards the test surface quickly and conveniently at up to 30mm/s. The additional second Z-axis in the QATM system offers a high-resolution positioning system for greater precision in force application and focusing.

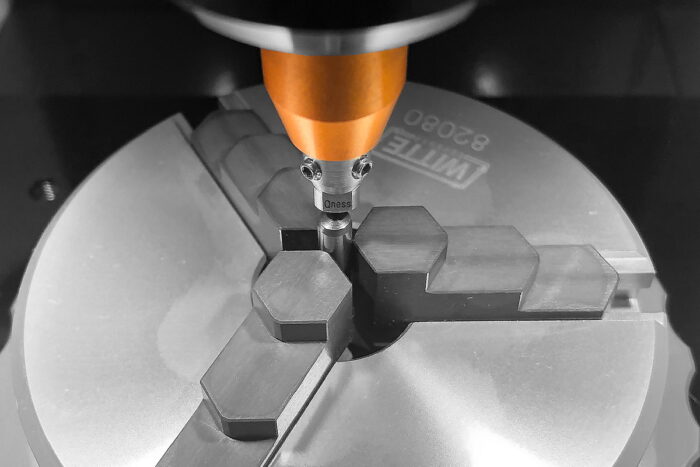

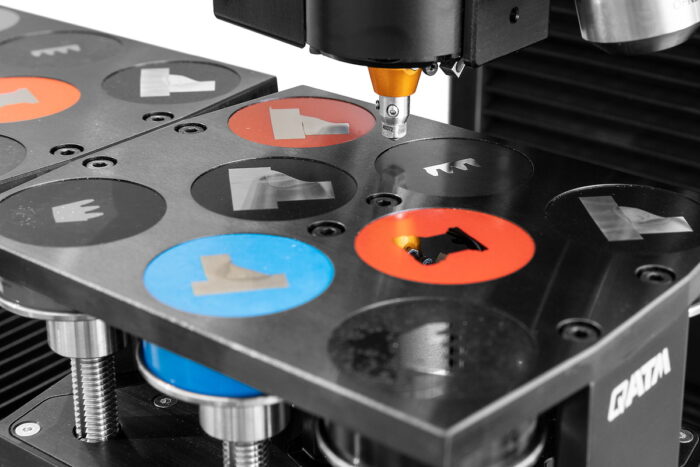

8-Position tool changer

Up to 8 different test diamonds or lenses can be mounted to the ultra-modern turret of the Vickers / Knoop / Brinell hardness tester. The compact structure is angled at 20° to guarantee excellent test room visibility. Highlight: The newly developed hardness testing modules serve as modular indenter holders enabling plug-and-play retrofitting of Brinell and Knoop test equipment at any time after delivery.

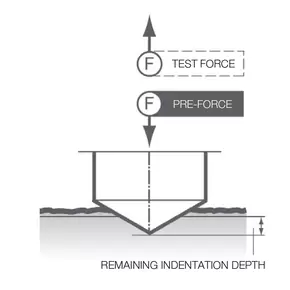

New Rockwell Test Method

In addition to the Vickers, Knoop and Brinell optical methods, Rockwell measurements can now also be carried out with the new micro hardness testers. A special Rockwell test module has been developed for this purpose.

CAS Technology

Innovative Collision Avoiding System (CAS) technology protects the mechanical parts in the device using predictive 3D motion calculations to visualize the effects of collisions and operation errors.

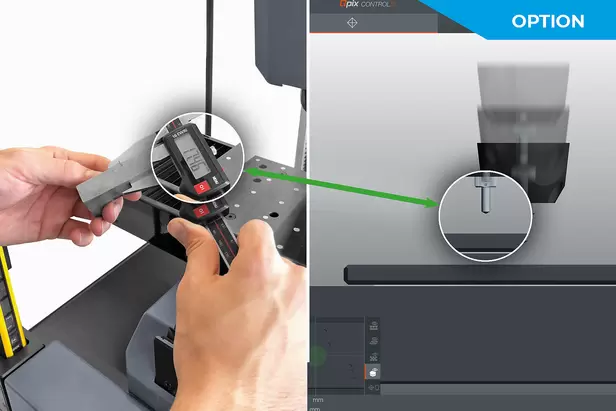

Digital caliper

The digital caliper is compatible with the Qpix Control2 system and reads the dimensions, height and diameter of components wirelessly and at the push of a button, entering them into the software. The test head height control in the A+ hardness tester enables the test height to be reached completely automatically with no need for manual input.

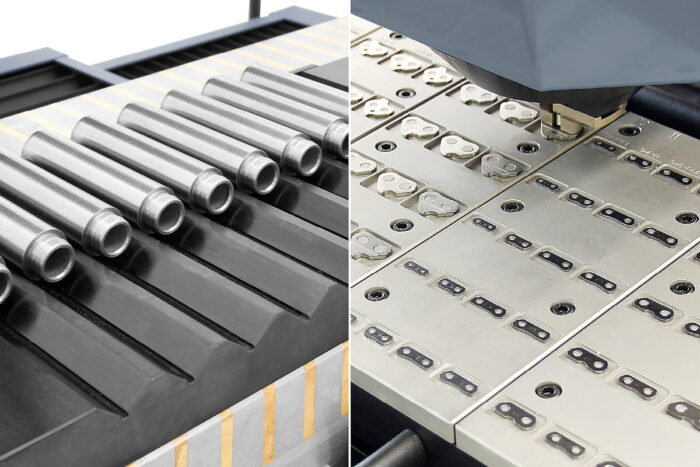

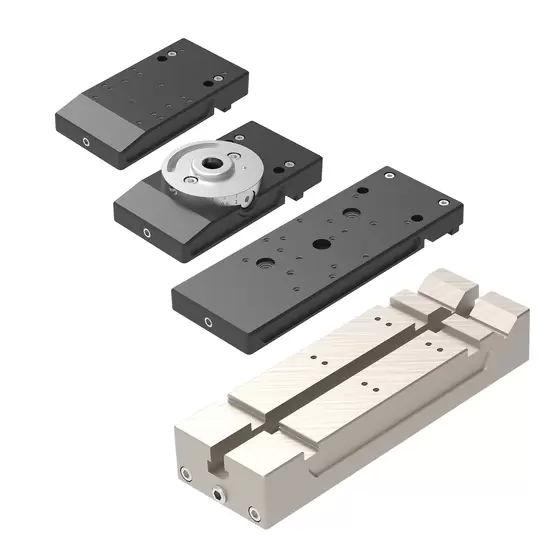

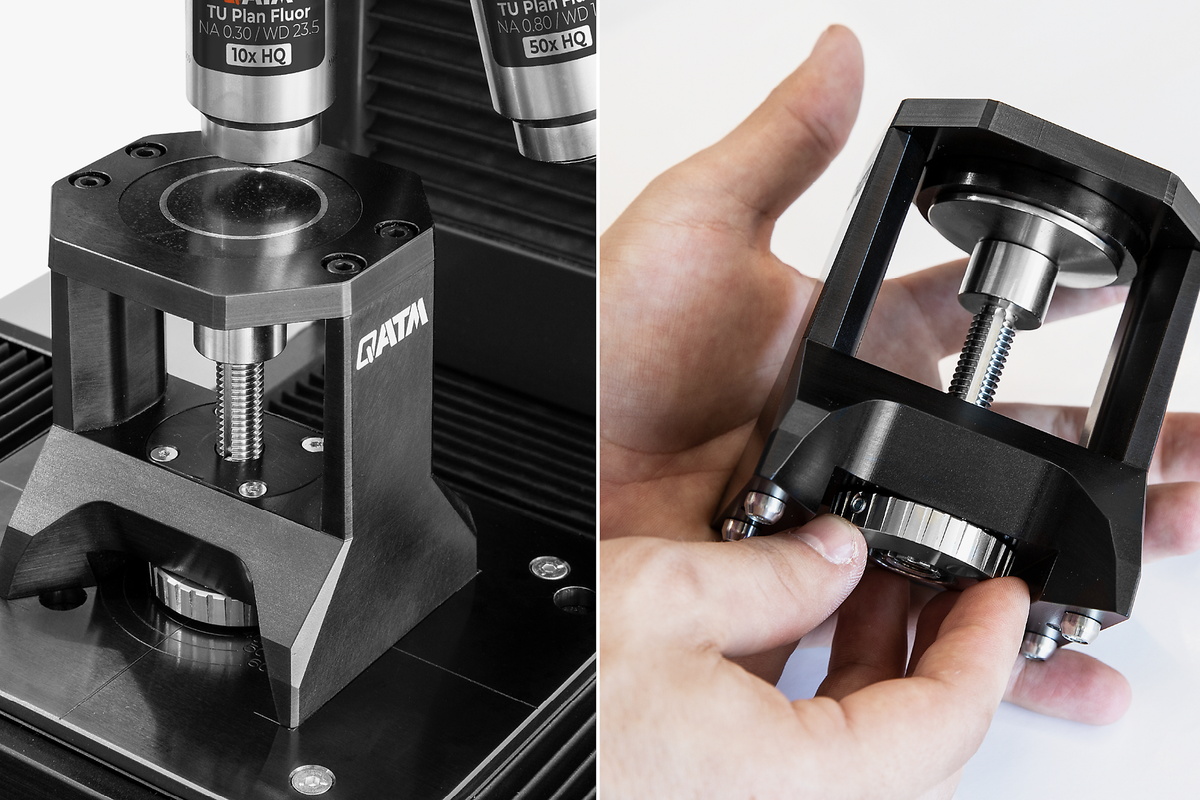

Sample holder Perfection in semi automation

QATM sample holders are designed to ensure accuracy and repeatability. In combination with the digital slide and data feedback, the machine produces perfect measurement readings

Pioneering technology – Unique implementation

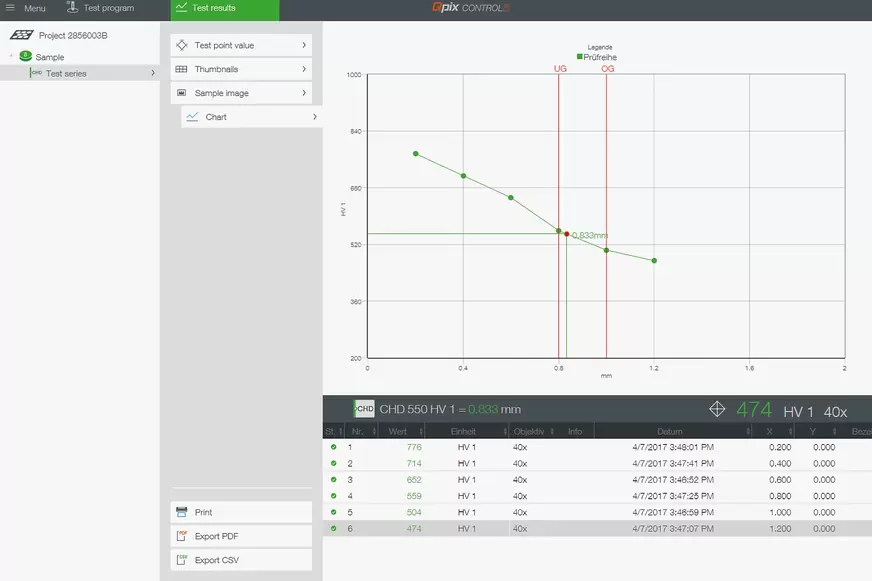

Qpix Control2M software

The Qpix Control2 M-Version of the intuitively-operated software is included with the Qness 10/60 M to provide sophisticated functionality tailored to the requirements of semi-automatic hardness testing devices. Clearly organized batch management and the effective use of templates from a broad span of testing projects, test result structuring and a complete range of background project information. The easily-generated templates include all the required information on test patterns, test methods, item names and user field details.

Digital cross slide with data feedback

Enables serial predefinition of test programs with fixed numbers of test points. If required, also with a manual slide, digital micrometer spindle and positional return – as used for manual CHD progressions.

Maximum versatility

Unsurpassed in single-piece testing and limited series tests on items of all sizes: Simple operability and optional additions for microscopy make QATM Qness 10/60 M a unique, high-quality, all-round package.

Optimized performance and silenced design

Optimized testing parameters and shorter intervals for serial autofocus, brightness regulation and image analysis, facilitate unbeatable cycle times during everyday operation involving hardness testing devices of the new micro hardness tester product line; and it’s even faster than the previous model. A further benefit of the new machine concept is the emphasis on reduced noise emissions in operation and motion, making it particularly suitable for laboratory work.

Comprehensive range of basic functions

Several labour-saving features are already included in the QATM base model:

- Optimized autofocus system

- Automatic brightness regulation

- Automatic image evaluation for hardness testing with multiple evaluation modes

- Built-in protocol generator

Surface Indentation Recognition

The adjustable surface indentation recognition function reduces the required eff ort of sample preparation for testing the hardness of non-optimum surfaces. Hence, automatic indentation recognition is also possible on critical surfaces (etching, grinding…).

Illuminated status display Brings light into the dark

The illuminated QATM logo displays the current device status at a glance. The range of flash intervals indicates whether the device is operating automatically or is free to be used for new tasks for staff all around the lab. Furthermore, not only does the LED test space lighting, installed as standard, allow samples and sample holders to be set up correctly, in the M version it guarantees uniform light intensity for working area.

Sample handling for individual & series testing

Embedded samples

The secure clamping of samples thanks to a redesigned holder with a built-in clamping force limiter, simplifies sample centering and positioning. A plate with a ball-joint even clamps specimen that cannot be held flat to prevent tilting or sliding during analysis. Available with 1, 4 or 8 holding positions and adapter rings for a large range of metric and imperial sample diameters.

Non-embedded samples

Components of almost all geometrical shapes can be fitted into the universal sample holder. Four clamping bolts can be set variably in various T-slots.

Special clamping devices

QATM is the right stop for advice on complex requirements and clamping devices! It would be our pleasure to advise, devise, customize and implement a solution for you. Only the right component clamping solution can guarantee reliable results.

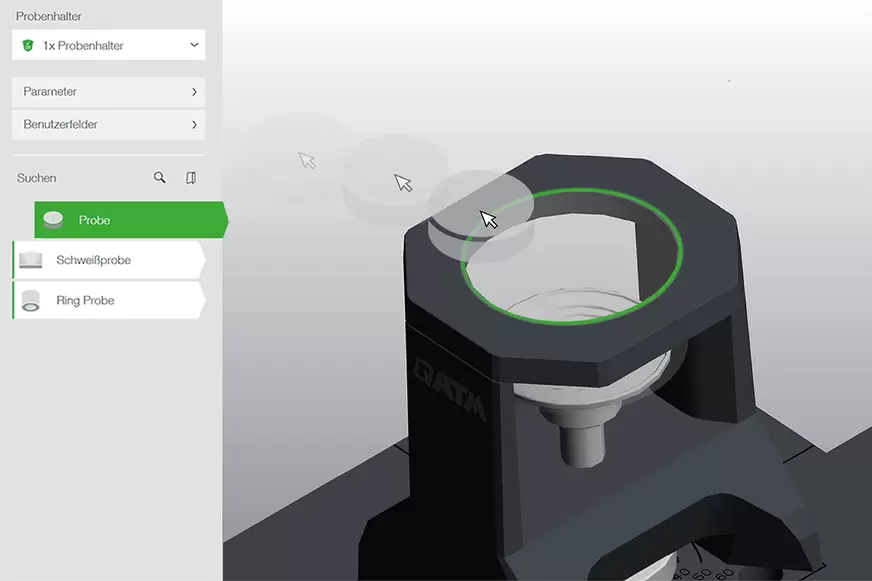

Revolutionary 3D operating concept Next-generation software for your hardness tester

The intuitive Qpix Control2 M-Version software is included with each Vickers / Knoop / Brinell / Rockwell hardness tester Qness 10 / 60 M to provide sophisticated functionality tailored to the requirements of semi-automatic hardness testing devices. Clearly organized batch management and the effective use of templates from a broad span of testing projects, test result structuring and a complete range of background project information. The easily generated templates include all the required information on test patterns, test methods, item names and user field details.

Load samples, load row, start 3 Steps to the result

1. Load samples

The machine moves automatically to the height of the sample holder.

2. Load row

Speedy row set-up: Drag the row of test points.

3. Start Test Sequence

The test sequence is executed according to the applicable hardness testing standards.

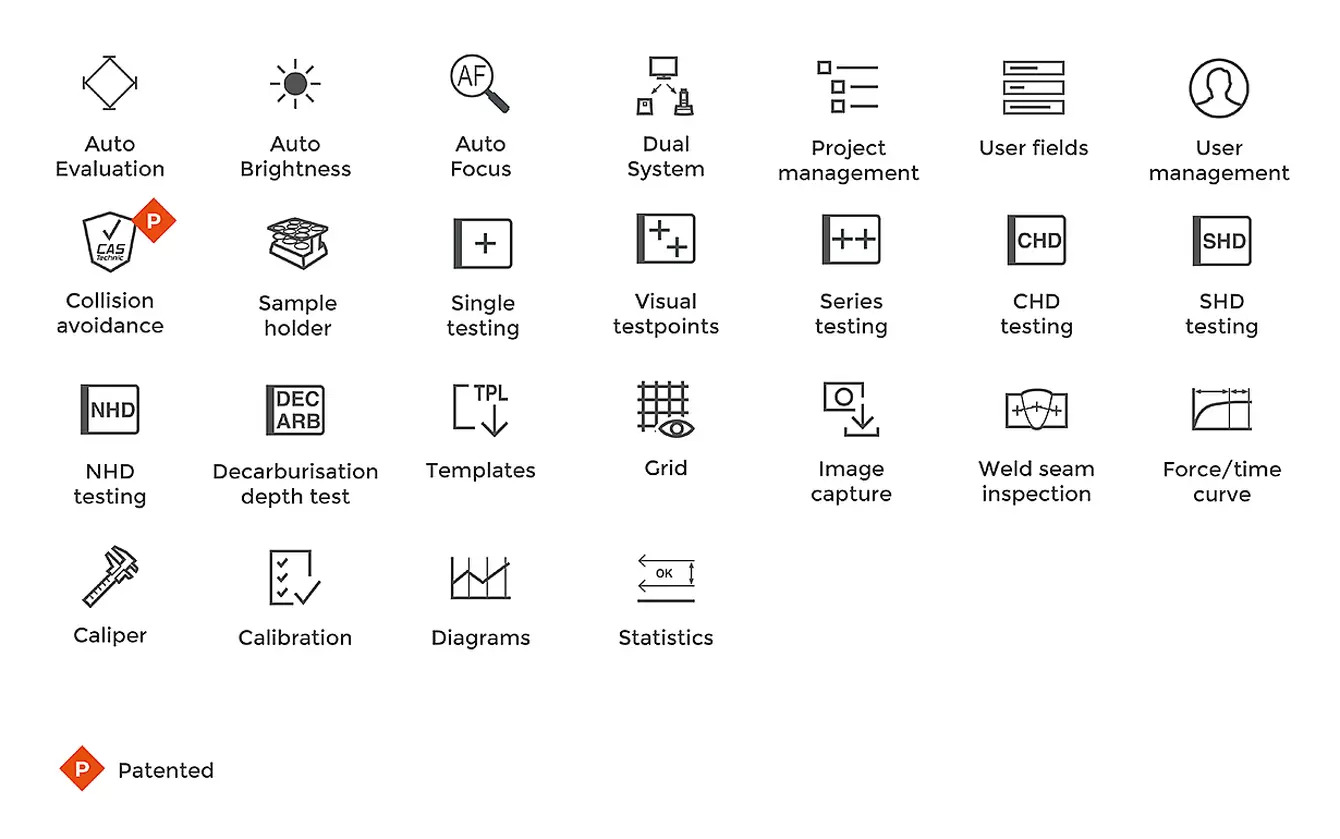

Standard Features

Optional features

Microscopy & Analysis

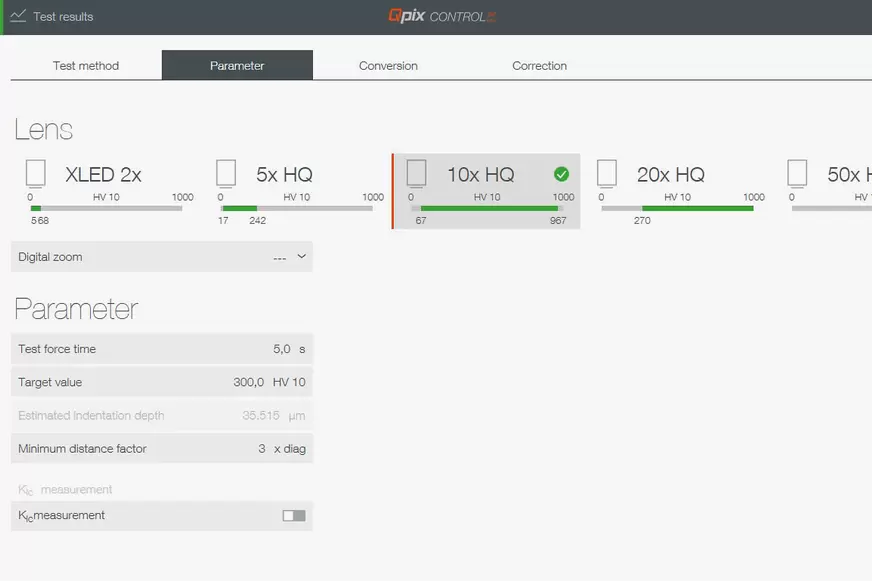

Simplified lens selection

Based on the selected method (e.g. HV10), the suitable hardness range is displayed for each lens, which can be measured. The most suitable lens is also highlighted.

Dual system

With the Qpix Control 2 software, several QATM devices (for example a Qeye 800 and a Qness 60 A+ EVO) can be operated with the same PC system. It is easy to switch back and forth between the two devices in the software.

Barcode/QR code/DMC reader

Qpix software platforms support barcode and QR code readers. Whether simply inserting header files (serial), managing the complete integration of reading devices for the automatic selection of templates, or calling up data from superordinate systems (optional) – barcode/QR code readers simplify work procedures for the tester, while also preventing operating errors.

Structural analysis made easy Qpix Inspect for microscopic evaluations

The intuitive and user-friendly Qpix INSPECT software functionality provides a comprehensive toolbox for microscopic evaluations and result documentation. The multifunctional software can be customized for customer-specific measuring tasks and complemented with add-on modules.

Inspect phase analysis

- Automatic image object dimensioning

- Evaluation of phase fractions according to ISO 9042 and ASTM E562

- Provides analytics results as percentage proportions of a surface or as nominal surface values as tables or diagrams

Inspect

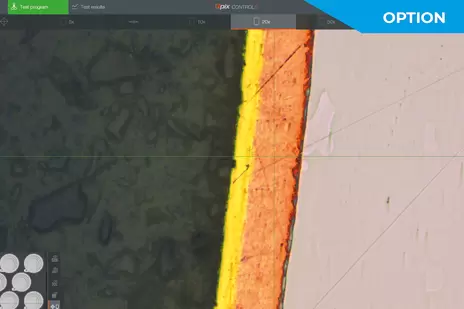

layer thickness measurement

- Determination of layer thickness according to DIN EN ISO 1463

- Semi-automated gauging of horizontal, vertical and radial layers

- Provision of layer thickness as statistical values for lengths as tables or diagrams

Inspect

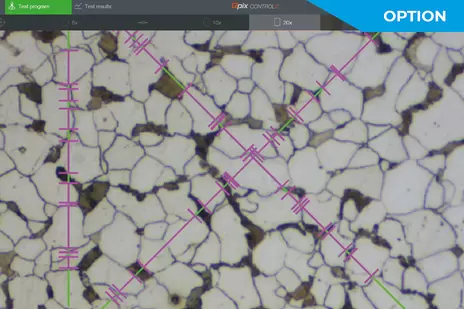

particle size determination

- Particle size determined according to DIN EN ISO 643 and ASTM E112 via linear or circular section method

- Results of the analysis provided as tables or diagrams

- Documentation of statistical characteristics of particle size and segment lengths cutting through the particles

Inspect

weld seam measurement

- Standardised measurement and evaluation of weld seams

- Prefabricated templates with all relevant measuring tools suchas throat thickness, weld reinforcement, penetration depth, etc.

- Automatic good/bad evaluation and report generation.

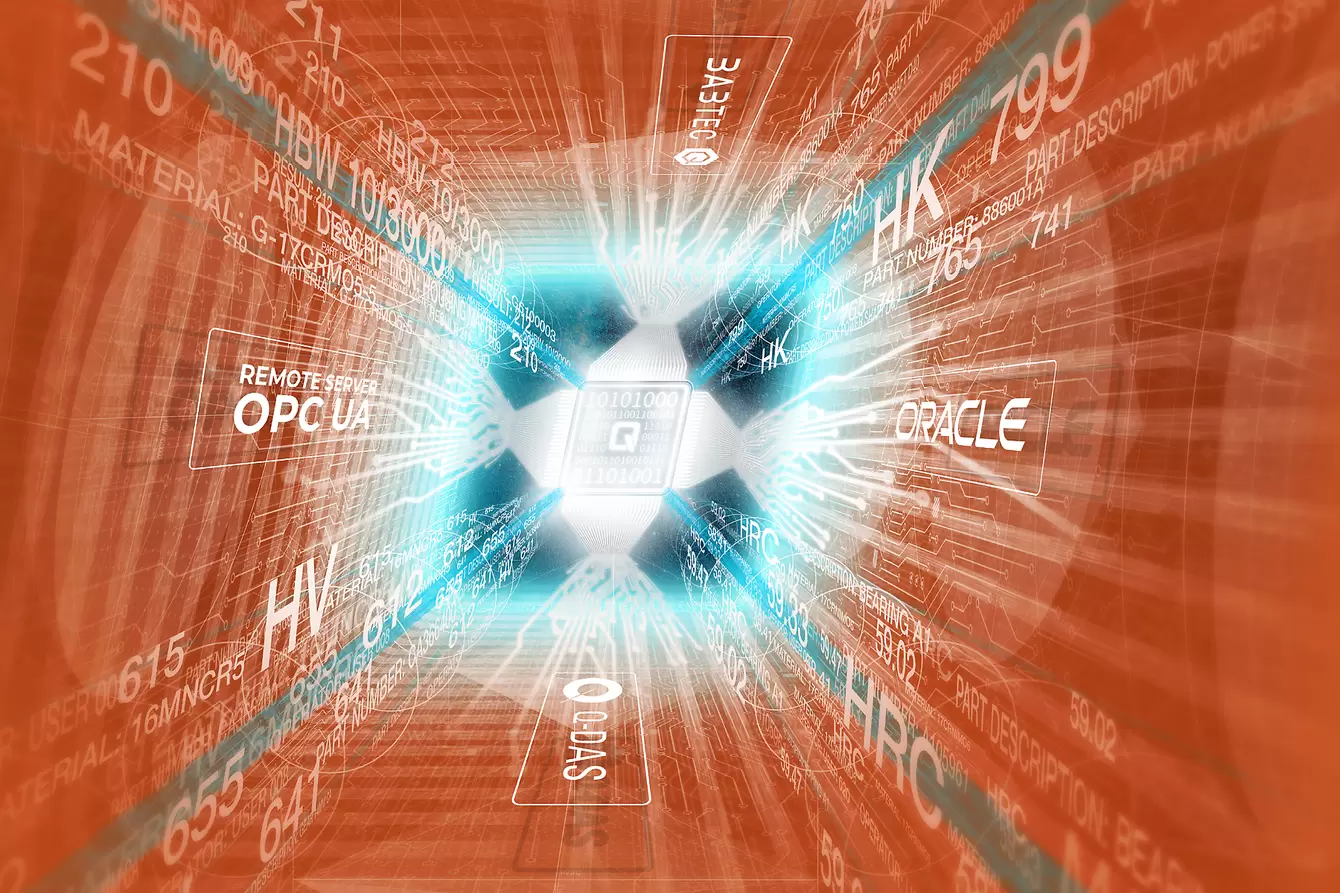

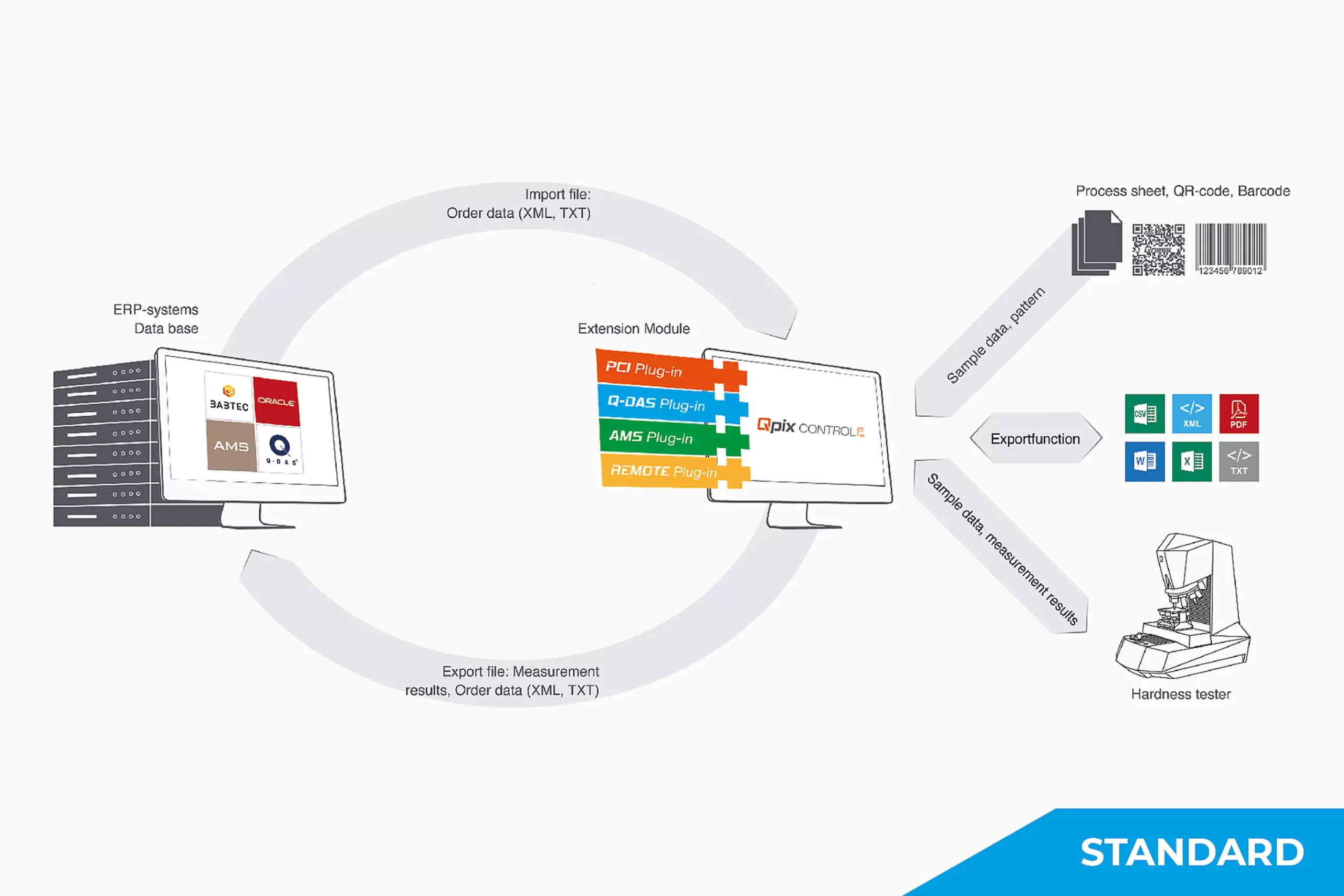

Industry 4.0 Qconnect for connected tomorrows

Qconnect is the interface in QATM Qpix Control2 software, providing customers with a full portfolio of inter-device connectivity – from serial production, open XML interfaces (bi-directional) and pre-specified plug-in solutions, such as the QDAS Plug-In+, through to customer-specific connectivity solutions implemented completely by QATM. We have a professional solution for every applicational requirement.

Available functionalities & formats:

REPORT, PRINT, PDF, XML IE, CSV, TXT, WORD, EXCEL, AUTO EXPORTER, MAIL, Q-DAS, AMS IE, IOT, LIMS, OPCUA, PCI IE (ERP, BABTEC, ORACLE, SAP)

Approved quality Calibration & Monitoring

Calibration Manager

This is a leap forward for calibration result management – The QATM Calibration Manager reminds operators of the necessary tests at freely definable intervals. Test results are added to the ongoing statistical record at the push of a button.

Premium hardness test blocks

Premium quality in comprehensive variety. Independent DAkkS (ISO/IEC 17025) calibration according to DIN EN ISO and ASTM including software for periodic norm-compliant tests.

Login via NFC

The Qpix Control 2 software supports user login using an external NFC reader. Depending on the NFC tag/card, the customer‘s existing access cards can also be programmed in, for example.