Speed – precision – cost efficiency

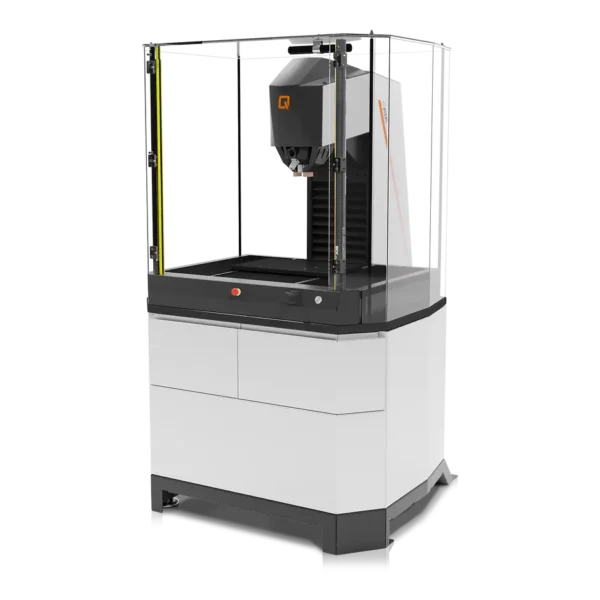

During the development of the Qness 200 units, particular attention was paid to the following things: Maximum performance with minimum effort.

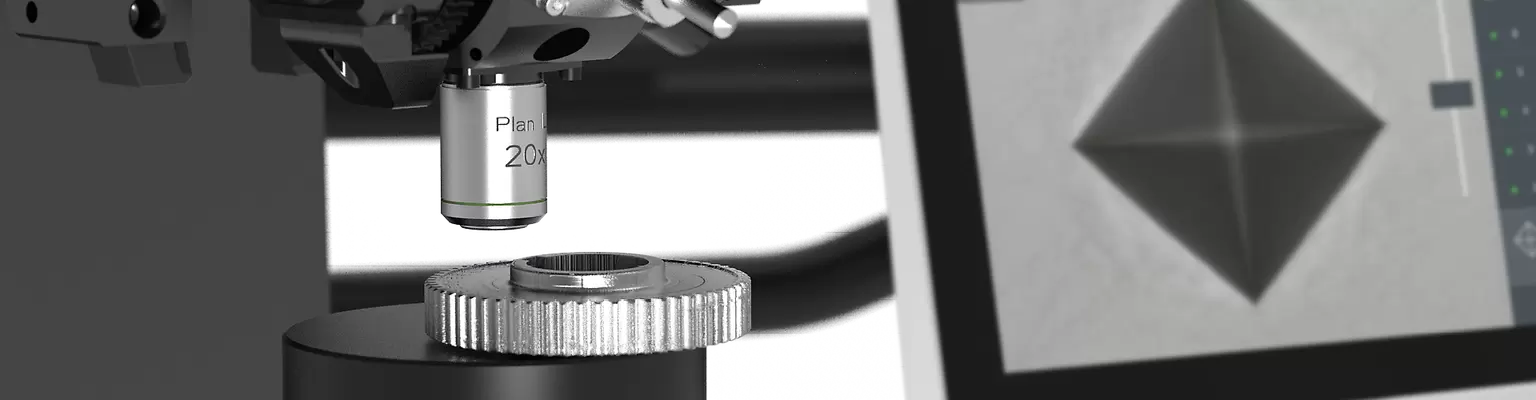

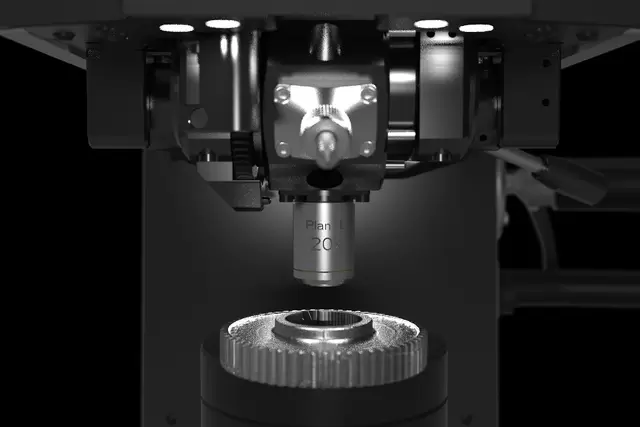

The proven concept with fixed test head and movable spindle, as well as its compactness give the Qness 200 CS its name, the precision-manufactured fivefold turret its speed.

With a test height of up to 250mm and a projection of 238mm, the Qness 200 is ideally suited for small to medium-sized parts.

Test methods and force application

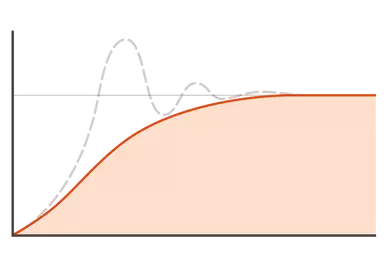

Fully automated test cycle

Electronic force application and closed-loop control

Integrated conversions: DIN EN ISO 18265, DIN EN ISO 50150, ASTM E-140

Highly accurate results in ultra-short time

Compact Design – Latest technology

- Test force ranges 0.5 kg to 187.5 kg

- Two machine versions to serve all applications and test piece sizes

- Direct depth measurement system with a resolution of 0.05 μm

- Robust, welded steel frame and covers made of sheet steel

Made in Austria

Unmatched in its class! We know how important a long-serving superior-quality device can be and guarantee excellent quality from our Qness 200 CS/CSA+ series. Developed and manufactured in Austria!

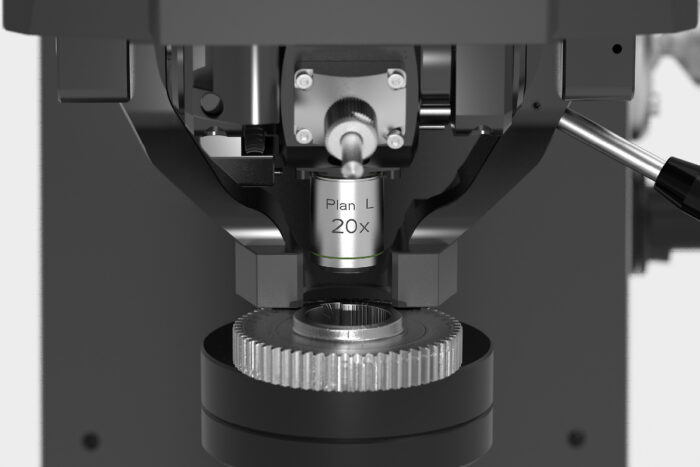

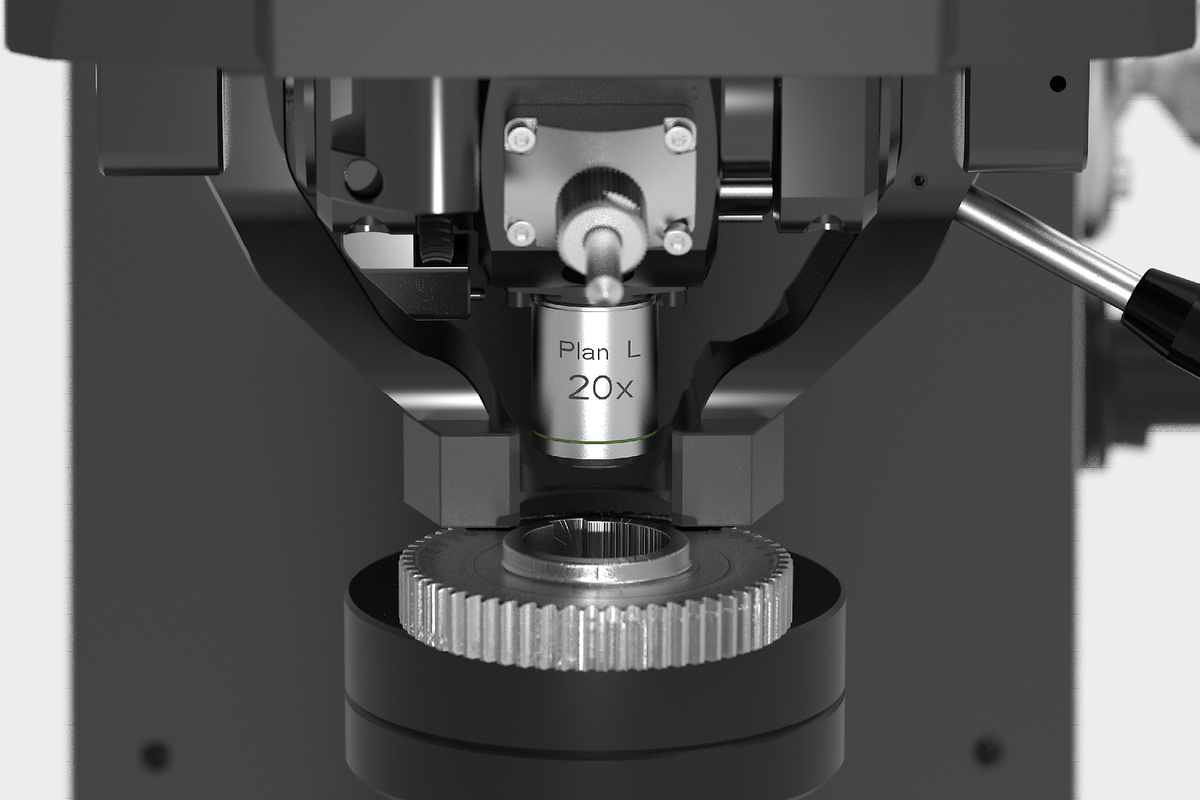

Xled Brinell Evaluation Lenses

XLED illumination modules revolutionize the analysis of Brinell indentations. Due to beading on commercially available lenses, soft Brinell indentations in particular can be subject to imprecise gauging results. In contrast, XLED lenses guarantee precise and repeatable measurements, regardless of material type and hardness, due to direct and wide-extension illumination.

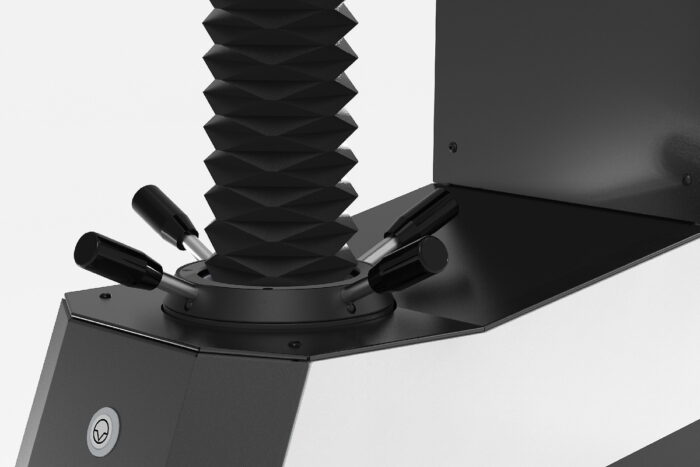

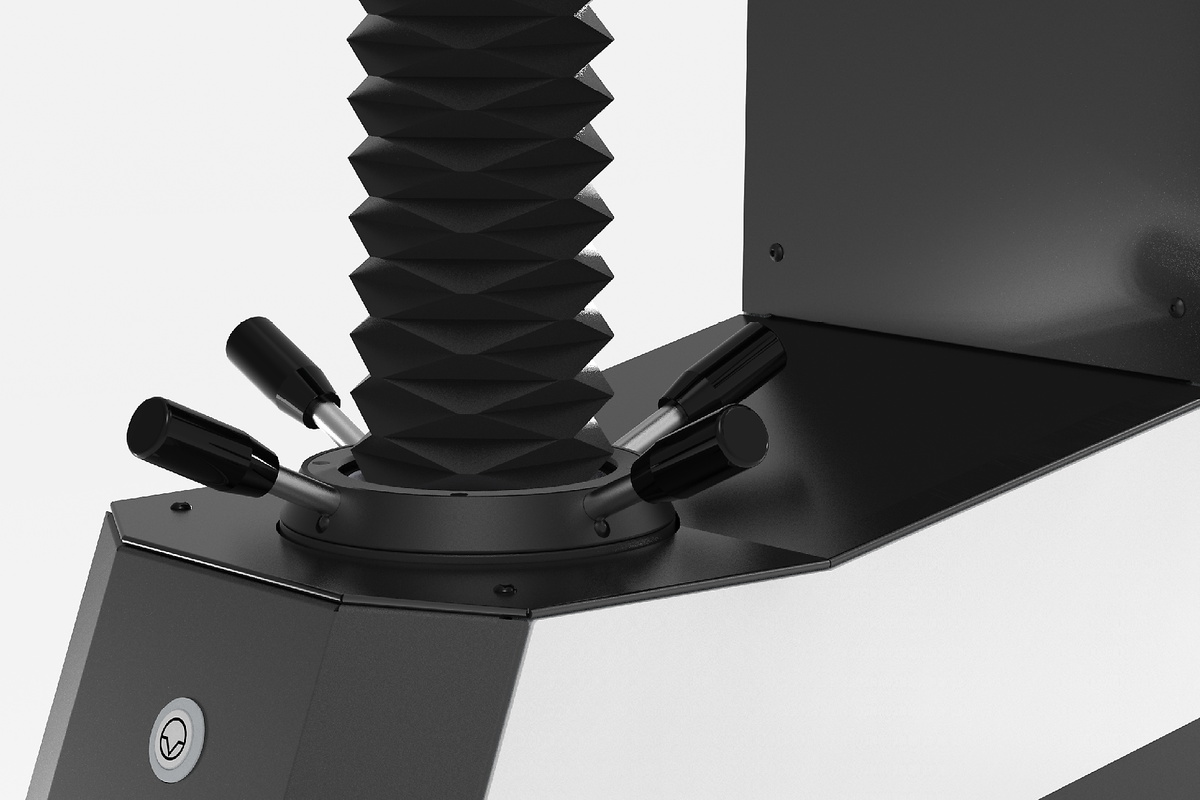

Swiveling Downholder

No long tool changeovers for inaccessible test positions. The downholder can be swiveled in and out via manual action. Furthermore, the clamping elements can be changed easily and adapted to suit the customer’s component.

Ethernet industrial color camera

High-quality CMOS 5-megapixel cameras with Ethernet data transfer define the current industrial standard. Unlike other camera systems, a far higher transmission stability is possible here. Additionally, the PC and hardness testing device can be set up remotely at great distances from each other. This is ideal in manufacturing environments in which the control infrastructure is installed in external switch cabinets.

Optimized test head design

A range of clamping and holding elements can be configured to suit tooling requirements. The optional transparent collision guard can protect tools on the device from damage while ensuring an unrestricted view of the test cell interior.

Test Table Height Adjustment

Height adjustment via stable, ultra-precise roller-bearing spindle guide. Solid, no-maintenance structure. All devices are available with a Ø 25 mm table mount (optional ¾” adapter available) facilitating the use of a wide range of test tables and devices.

Rapid Indenter Changing system

Uniquely simple, tool-free indenter changes due to indenter quick-release mechanism.

Faster Test Method Change-Over 5 position tool changer

Simply cover universal applications: the concept with horizontal rotary axis combines space for 5 tools in a uniquely compact design. Three-sided closed elements ensure secure workpiece clamping close to the test point, even with small components.

Fast, quiet and universally applicable

Freely adjustable operating display

The 12” ultra-flat, capacitive touch display can be raised, lowered and tilted smoothly via ball-and-socket joints for ergonomically optimized use.

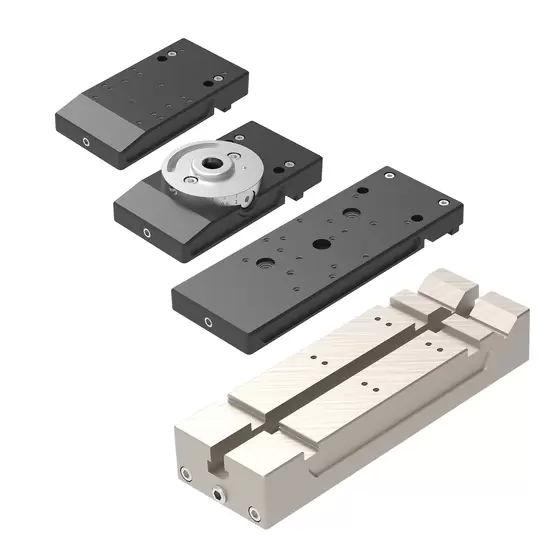

Wide Range of Test Tables and Prism Anvils

The wide range of available test anvils and prisms enable hardness testing to be conducted on unusually large or spherical items, and on test objects with an uneven test surface.

Basis for bi-directional data link-up

All Machines of the ECO series can, if required, be equipped with a desktop PC system. Customers can provide their own PC system and use it to control their hardness tester.

Workspace illumination

The bright, uniform LED workspace lighting enables safe positioning of the test part. The workspace lighting is designed to illuminate the test area without disturbing shadows.

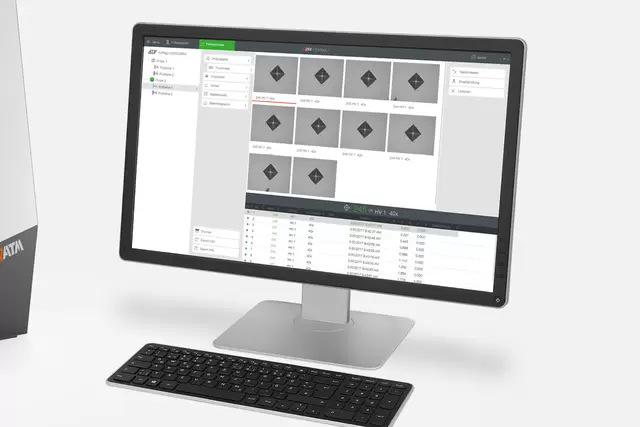

Qpix T2 full screen mode Clear focus on essentials

Result Overview

The most important information is centralized and displayed in a main screen, so that user-friendliness and, above all, the test results are in focus. Functions: measurement list, progress curve, statistics, distribution, live force/time progress

Multi-touch capacity for ultra-simple operation

Modern multi-touch operation for simple zooming and easy menu navigation.

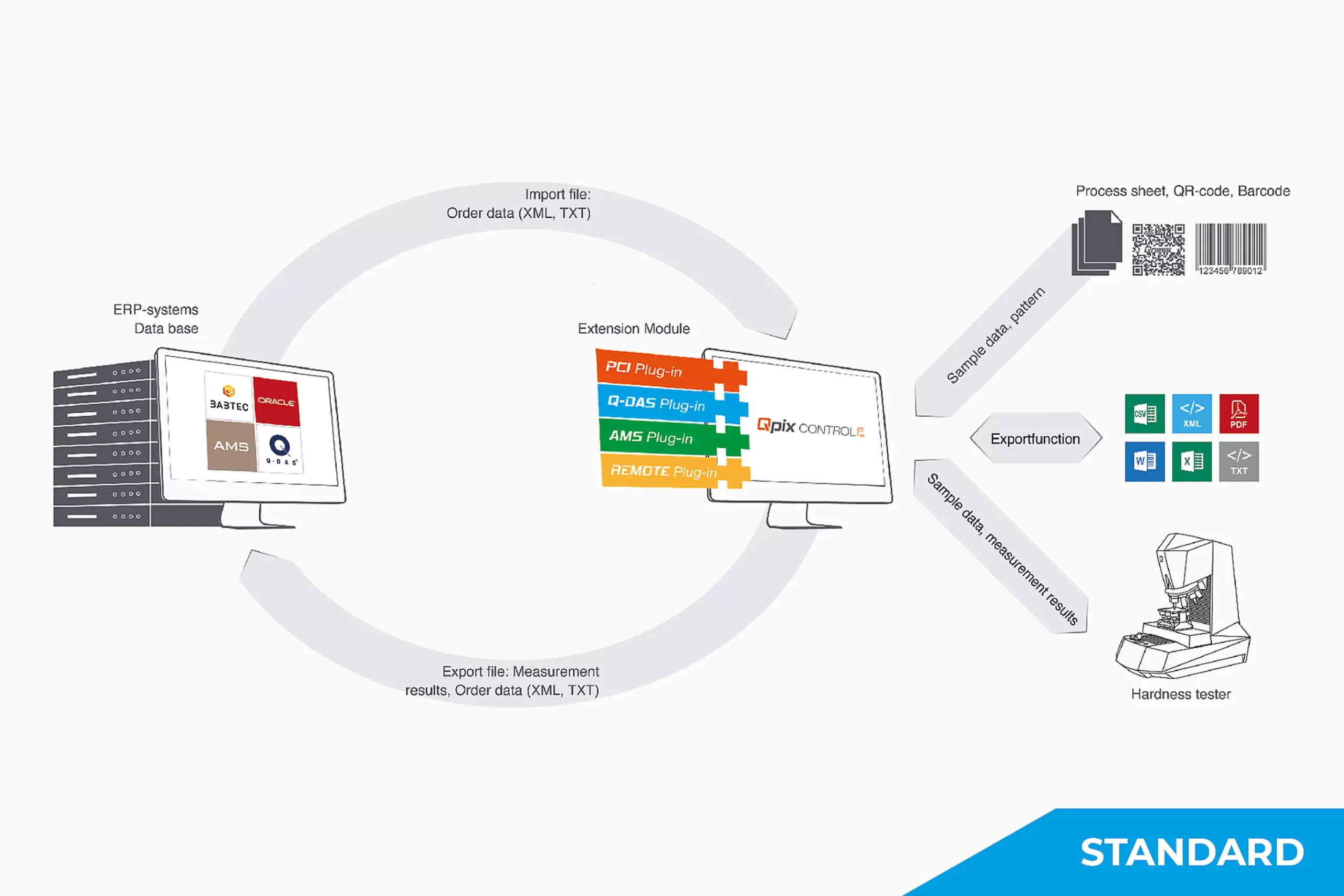

Industry 4.0 Qconnect for connected tomorrows

Qconnect is the interface in QATM Qpix Control2 software, providing customers with a full portfolio of inter-device connectivity – from serial production, open XML interfaces (bi-directional) and pre-specified plug-in solutions, such as the QDAS Plug-In+, through to customer-specific connectivity solutions implemented completely by QATM. We have a professional solution for every applicational requirement.

Available functionalities & formats:

REPORT, PRINT, PDF, XML IE, CSV, TXT, WORD, EXCEL, AUTO EXPORTER, MAIL, Q-DAS, AMS IE, IOT, LIMS, OPCUA, PCI IE (ERP, BABTEC, ORACLE, SAP)