Features

- ULPA filters (as per IEST-RP-CC001.3 and HEPA (H14) filter as per EN 1822) with a typical efficiency of >99.995% at 0.1 to 0.3 microns, providing ISO Class 3 air cleanliness as per ISO 14644-1

- FDA-grade pressure-tight static seals

- Sentinel™ Gold microprocessor controller supervises all functions and monitors airflow and pressure in real-time

- Robust dual-wall construction. Unique Esco Dynamic Chamber™ plenum surrounds filter seals with negative pressure

- Safe-change cuff rings permit hypalon sleeve changes with zero risk of work zone or environment contamination

Principle

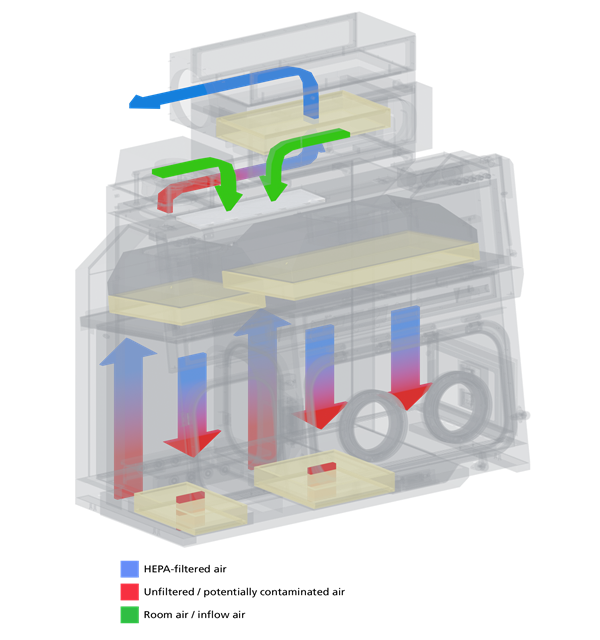

Total Exhaust

- Ambient air is pulled through the inlet pre-filter and main filter via the main fans at the top of the isolator. This creates positive pressure on the plenum which provides the downflow of air with a velocity of 0.40 m/s ± 20%.

- The pre-filter extends the life of the filters by trapping larger particulates that can easily clog the main filters

- This downflow supply then provides an ISO Class 5 environment and unidirectional airflow inside the isolator; thus, protecting the materials inside the main chamber and pass-through.

- Air from the work zone and pass-through is then quickly purged by the fans to keep the area clean. The purge is completely exhausted through HEPA filters as well; ensuring that only clean air is exhausted back to the environment.

Models

| Guide to Isolator Class III Models | |||||||||

| SCI-2G8-N3SL-III-EG | |||||||||

| Isolator Unit | Model | No. of gloves – Nominal Width | Electrical Requirements | Code | External Construction | ||||

| Streamline® Compounding Isolator (SCI) | SCI | 2G | 5 ft (1.6m) | 8 | 220-240 V AC, 50/60Hz, 1Ø | N3 | Process zone: -125 Pa | EG – Electrogalvanized Steel | |

| 3G | 6 ft (1.95m) | 9 | 110-120 V AC, 50/60Hz, 1Ø | Pass-through zone: -75 Pa | SS – Stainless Steel 304 | ||||

Upon ordering, input material of construction at the end of the model code: SCI-2G_-N3SL-III-SS or EG

- SS: Full SS 304 stainless steel exterior

- EG: Electrogalvanized steel with ISOCIDE™ coating

Accessories

Standard Accessories

- Electromagnetic interlocking doors to prevent cross-contamination

- Foot switch included to easily open the inner doors

- Single-piece or multi-piece stainless steel 316L work top

- Energy efficient LED lighting with higher durability and better quality

Electrical Outlets and Utility Fittings

- Electrical outlet, ground fault, North America

- Electrical outlet, Euro/Worldwide

Support Stands

- Fixed height, available 711 mm (28″) or 864 mm (34″) – With levelling feet, ± 38.1 mm (1.5″) (SAL) – With casters (SPC)

- Telescoping height stand for levelling feet (STL), nominal range 660 mm to 960 mm (26″to 37.8″)

- Telescoping height stand for casters (STC), nominal range 660 mm to 880 mm (26″ to 34.6″) – Adjustable in 25.4 mm (1″) increments

- Infinitely adjustable hydraulic stand with casters elevates to accommodate a sitting or a standing user’s work surface height (SHM)

Other Accessories

- External material of construction:

- Electrogalvanized steel with ISOCIDE™ powder coating

- Stainless steel 304

- Carbon Filter

- IV bar, with hooks

- UV lamp

- Manual Latches

- Manual Volumetric Damper

- Top Exhaust collar

- Side Exhaust Connection

- Anti-blowback valve

- Perforated shelf to increase work zone space

- Alarm package

- Adjustable foot rest

- Monitor System

- Mounted on the rear of the isolator

- Beside the front panel; equipped with a keyboard and mouse arm

- Glove Leak Tester

- Automated pressure hold testing (APHT)

- With Mobile Compressor

- Without Mobile Compressor

- CCTV integration

- On the side of the process chamber with acrylic viewing panel

- Back-up battery for the electromagnetic interlocks (contact Esco for more information)