RoboDis II+ is the only simultaneously operating, fully automatic dissolution test system currently on the market. All stages of the dissolution processes are computer-controlled and are therefore carried out completely without user intervention.

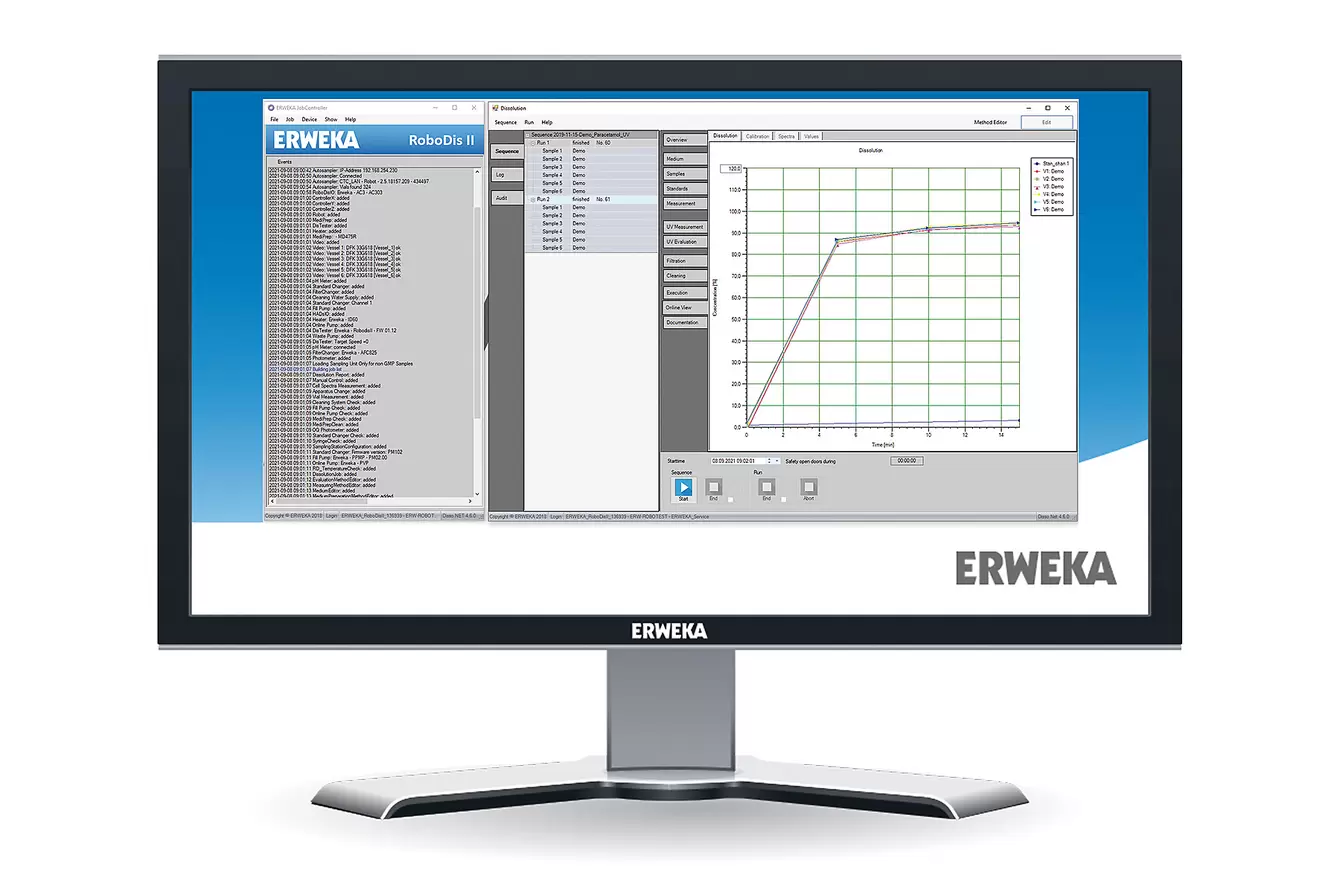

The key element of the fully automated system is the Disso.NET software developed by ERWEKA, which controls all system functions, including precise movement of the robot arm, control of the analyzers, data processing and full documentation.

In the standard configuration, the RoboDis II+ tests up to 10 batches according to USP methods 1 (basket) or 2 (paddle). The parallel sampling approach enables very short cycle times for recording detailed drug release profiles, which can be selected by the user. Integrated System Suitability Tests (SST) and video monitoring ensure a high level of reliability. Like all ERWEKA products, the RoboDis II+ is fully USP / EP / JP compliant.

Fully Automated Dissolution System RoboDis II+

Small Footprint, Great Results

Three complete semi-automatic dissolution testers including media preparation and vessel cleaning – that’s how much floor space can be saved with a RoboDis II+ 10-batch system that requires no more than 2×1 m of floor space. With the RoboDis II+, the entire dissolution process can be automated. This enables fully automated testing, including set-up, media preparation and the automatic cleaning process.

Advanced Resolution System With Numerous Functions Versatile Applications

Productivity Booster RoboDis II+ for Quality Control

- Planned productivity to suit your requirements with 10 or 40 batches

- Non-stop testing: high sample volumes – 40 batches

- Parallel action

- Robotic precision & fault monitoring

- Space-saving footprint

Flexible Specialist RoboDis II+ in R&D

- Multiple dosage forms

- Flexible filtering options

- pH change: half change and optional full change

- Various options for connecting to analytic devices

- Six reference standards

HPLC Injection & Autosampler Workflow

Innovative Robodis II+ Safety Systems Not Smarter, but More Reliable

RoboDis II+ performs routine tasks more precisely than any human operator – but without a human operator, all its powerful, fully automated functions would be of no value. It is the operator who defines the test methods, checks the plausibility of the results and interprets the obtained data. To enable the operator to focus on these tasks, the RoboDis II+ has been equipped with a range of safety functions.

RoboDis II+ Key Element Disso.NET

The RoboDis II+ is operated fully automatically via its integrated controller, which is equipped with the Disso.NET software. The software, specially developed by ERWEKA for this purpose, is the key element of the RoboDis II+ system: the desired dissolution test methods can be defined and started using a user-friendly editor. Disso.NET then controls all steps of the dissolution process from media preparation to analysis. The software also controls the precise movement of the robot arm and the connected analyzers. Disso.NET logs all test results and times, automatically creating an audit trail. Once the test is complete, the software generates comprehensive reports and allows all results to be exported. In addition, the software controls the System Suitability Tests (SST) and the video recording functions.

Human-Error Proof Real 24/7 Testing

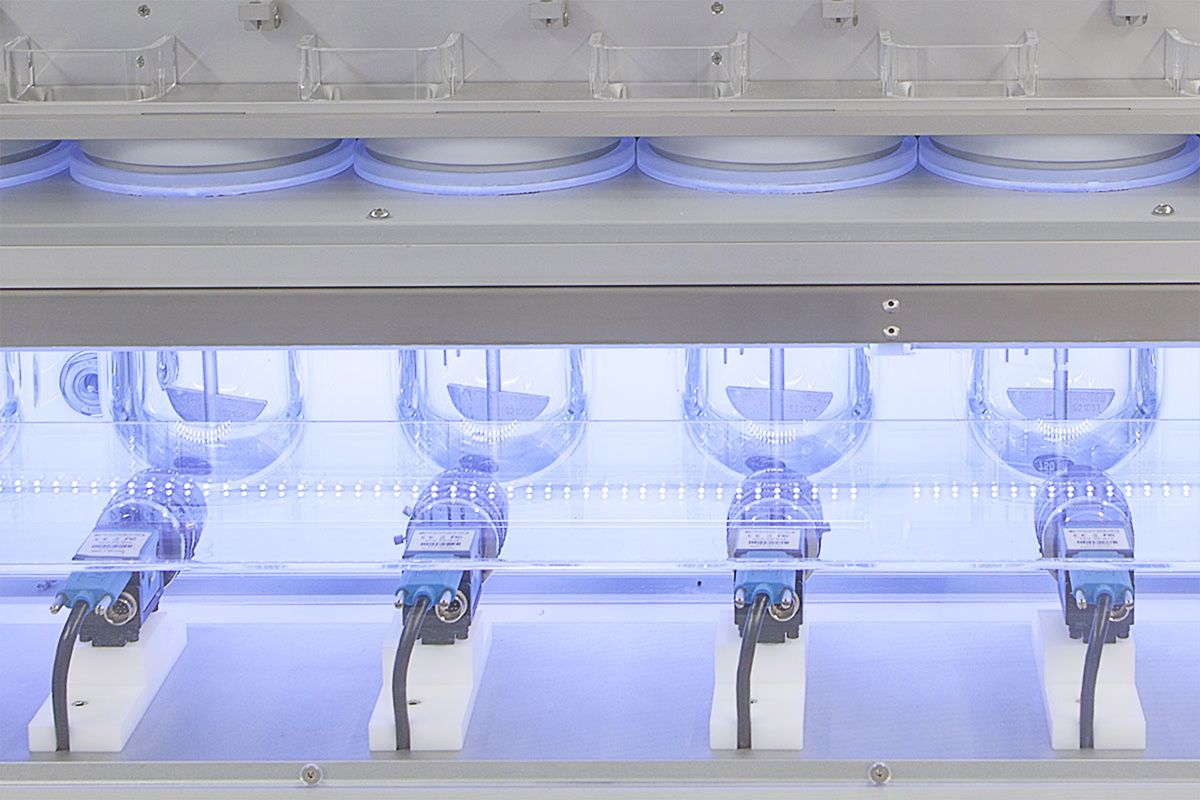

Thanks to the newly developed LED light strip, the water bath can also be illuminated at night, making 24-hour video recordings possible without the need for external lighting. The LED light bar is very energy efficient and provides the perfect brightness for the new gigabit Ethernet camera system. The RoboDis II+ supports up to six of these new cameras, which are simply connected to the controlling PC using the existing Ethernet network connection in the RoboDis II+.

Perfect for High Volume Testing Highly Productive: 40-Batch Solution

Our 40-batch magazine for the RoboDis II+ ensures fully automated dissolution test runs with up to 40 sample batches. In addition to the 40-batch sample holder, the RoboDis II+ also offers a 40-batch filter holder. In combination with the LED light bar, the RoboDis II+ is now able to continuously test samples 24 hours a day, 7 days a week.

Fully Automated Dissolution System RoboDis II+

Product Highlights

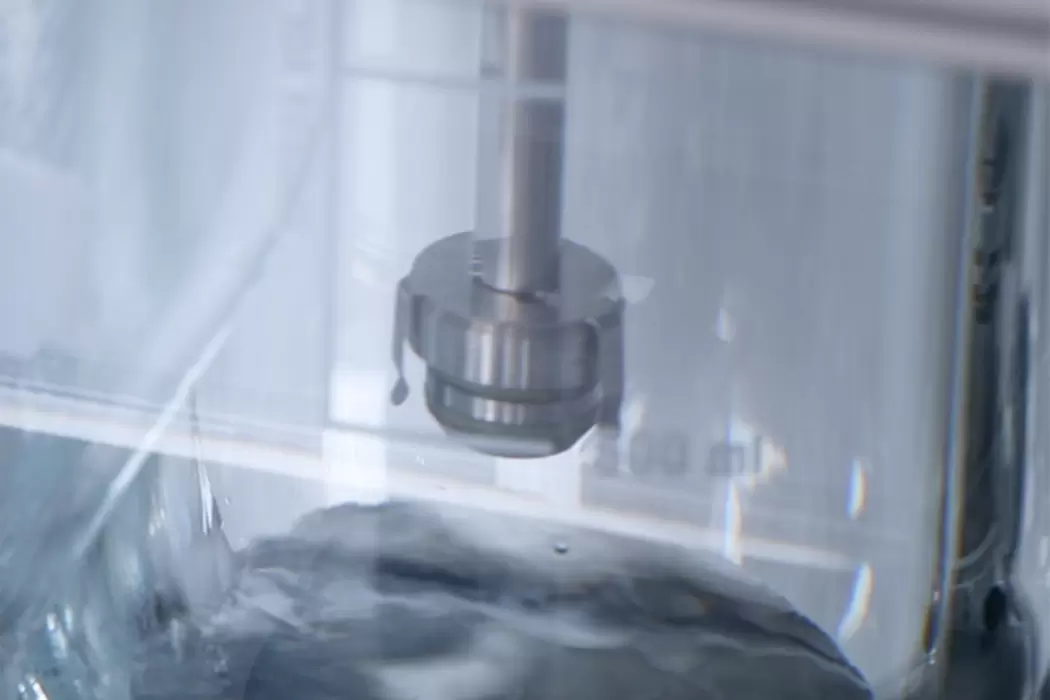

Robotic Arm

At the core of the RoboDis II+ testing process is our advanced pneumatic robotic arm. This arm assembles all samples, adds and removes filters and is even responsible for filling and cleaning the vessels, saving operators an enormous amount of time on these repetitive tasks.

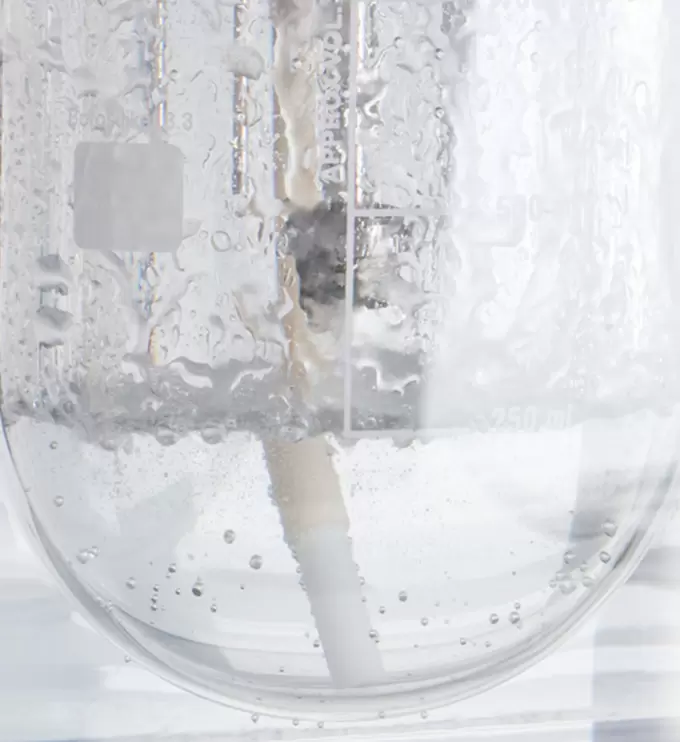

Seven Test Vessels

Seven USP-compliant test vessels in the RoboDis II+ system support testing in R&D and quality control. In quality control, for instance, six samples can be compared with a reference sample. Alternatively, seven different samples can be tested in parallel in R&D.

Video Recording

The RoboDis II+ is equipped with 6 video cameras and an LED light strip. The water bath can be easily illuminated and the new video capturing capabilities can be used without external lighting. In addition, video recording of the dissolution process is possible in time-lapse mode.

Baskets, Paddles & Sinkers

The RoboDis II+ supports the use of both paddles (USP 2) and baskets (USP 1), both of which can be exchanged by the user. It also supports the use of sinkers measuring up to 34 mm. The dropping and removal of sinkers is fully automatic using the sinker tool supplied.

Sample Magazine for 10, 20 or 40 Batches

In the version with 40 batches, the RoboDis II+ enables genuine 24/7 testing and is able to process 40 batches without human intervention.

pH Changes

The optional pH measurement permits pH changes according to USP method A (half change) and method B (full change).

Filter Magazine

Poroplast filters are fitted fully automatically by the robot arm for each test.

Online UV-Vis Analysis or HPLC

RobDis II+ supports integrated online UV-Vis or HPLC analytical devices. The samples are taken fully automatically and transferred to the analyzers.

Premium Service for a Premium Product 360° Service

Installation

One-week professional installation and commissioning of the RoboDis II+ by certified ERWEKA technicians

Qualification

Professional implementation of the necessary qualifications for the RoboDis II+

Preventive Maintenance

Preventive half-yearly maintenance services ensure a long service life for the RoboDis II+

Device Trainings

Profound user knowledge through hands-on courses and training

24h RoboDis Hotline

Personal advice and direct clarification of questions through a 24-hour RoboDis hotline

Fast Repair Service

Reliable, quick repair service by highly qualified staff or directly at the ERWEKA premises

Service Contracts

Customized service contracts to ensure the durability and high precision of the testing equipment and maintain control of operating costs for years to come

Highly-Qualified Customer Support

Powerful, global service network with highly qualified and experienced service employees

Fully Automated Dissolution System RoboDis II+

Key Features

Technical Data

| Weight | 760 kg, note floor load capacity |

| Dimensions Housing, Transport (H x W x D) | 1800 x 2020 (total) x 1020 (total) mm |

| Dimensions Housing, Installation (H x W x D) | 2800 x 2020 (total) x 1300 mm |

| Power supply: Type | Tri-phase four-conductor system (L1-L3/N/PE) |

| Operating voltage | 400 VAC, 50/60 Hz |

| Control voltage | 24 VDC |

| Power rating | approx. 5.2 kW |

| Fuse | 32 A |

| Water | Connections for cleaning and demineralized water max. 5 bar (0.5 Mpa) set to approx. 3-4 bar for MediPrep max. 60 °C Connection for 1/2-inch hose |

| Connection for waste water with low contamination level | Connection for 3/4-inch hose |

| Connection for waste water with high contamination level | Connection for 3/4-inch hose |

| Height of the waste water connections | Max. 20 cm above the ground |

| Connection for media tank | Norprense® hose ID 1/4-inch |

| Doors | Two-leaf, makrolon, transparent, safety lock |

| Robot Supplier | Festo |

| Model | RP (room portal) |

| Frame material | Aluminium |

| Operating range | 1420 mm x 540 mm x 600 mm (xyz) |

| Interfaces (control) | ModBus TCP/ EtherCAT |

| Interfaces (configuration) | Standard Ethernet LAN |

| Angle of rotation | 180° (electrical rotary drive) |

| Robotic tools | Filling and cleaning tools, pH probe |

| Number of testers | 1 |

| Test stations | 7 in a row |

| Test station connections | With toothed belt and gear wheel |

| Agitators (shaft and stirring elements) | Stainless steel 1.4571 (316Ti) |

| Stirring element | Paddle (standard), basket (optional) |

| Operation | DC motor with speed sensor, sequential agitator switch (stepper motor) |

| Vessel | Glass (borosilicate) |

| Evaporation | Less than 1% in 24 hours |

| Time measurement | Time in realtime, tolerance ± 1 sec. |

| Temperature measurement | PT 100 sensor |

| Temperature control | ± 0.1 °C |

| Temperature in the vessel | 37 °C ± 0.5 °C; temperature range +4 °C (RT) to 40 °C ± 0.5 °C |

| Stirring speed | 25 min ± 2 min up to 200 min ± 4 min |

| Water bath | Acrylic glass |

| Water bath volume | Approx. 30 l |

| SPS | CodeSys Version 3.5 |

| Other connections | PT 100 connection, heating connection and interface |

| Control/operation | Controller, monitor, keyboard, mouse, WIN software |

| Software | ERWEKA Disso.NET software, video software |

| Heating system | Flow-through, type ERWEKA DH 1520 |

| Heating capacity | 1500 W |

| Flow-through speed | 6 l/min |

| Interface | RS 232 |

| Automatic production/degassing/heating | MediPrep (ERWEKA) |

| Production | Made from up to 6 concentrates + de-ionised water or pre-mixed medium; Vmax MediPrep: 8000 ml |

| Degassing | Vacuum > 190 mbar absolute |

| Heating | Flow-through heating 1500 W, max 40 °C |

| Dosing | Dosing via filling pump |

| Scale | SST with load cell |

| Pump type | Piston pump, ceramic head |

| Pump Interface | RS-232 |

| Vessel filling | 250 ml – 1000 ml +- 1% (volumetric filling) |

| Magazines, basket | Two, each with 6 x 10 rows – USP Method 1 (only for 40-batch) |

| Magazines, tablet holder | Tablet size max. ⌀ 35 mm |

| HPLC device | max. 2 HPLC systems |

| Automatic filter changer (opt.) | AFC (ERWEKA) |

| Flow-through cuvette (opt.) | 1-10 mm |

| Cleaning: Suction pump | CP 7+ diaphragm pumps |

| Cleaning: Flow-through | Approx. 1000 ml/min |

| Cleaning: Hoses | Norprene® |

| Protection type | I/EN 61140 |

| Protection class | IP 21/IEC 529 |

| Ambient temperature in operation | +10 °C to +30 °C (Ambient temperature at least 5 °C lower than test temperature) |

| Storage and transport temperature | +5 °C to +40 °C |

| Relative humidity | 25 to 80 % non-condensing |

![llproductsdissolution-robodis-ii-robodis-ii[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/llproductsdissolution-robodis-ii-robodis-ii1-700x700.webp)

![pic-dt-robodis-ii-basket-adaption700[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-basket-adaption7001-700x467.jpg)

![pic-dt-robodis-ii-handling-inline-filter700[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-handling-inline-filter7001-700x467.jpg)

![pic-dt-robodis-ii-40batch-filter[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-40batch-filter1-700x467.jpg)

![pic-dt-robodis-ii-sinker-handling-krzer[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-sinker-handling-krzer1-700x467.jpg)

![pic-dt-robodis-ii-40batch-closeup[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-40batch-closeup1-700x467.jpg)

![pic-dt-robodis-ii-robo-led[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-robo-led1-700x467.jpg)

![pic-dt-robodis-ii-sst-cap-11[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-sst-cap-111-700x467.jpg)

![pic-dt-robodis-ii-ph-meter582[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-ph-meter5821-700x467.jpg)

![pic-dt-robodis-ii-mg-0836[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-mg-08361-700x467.jpg)

![pic-dt-robodis-ii-analysis[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-analysis1-700x467.jpg)

![llproductsdissolution-robodis-ii-robodis-ii[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/llproductsdissolution-robodis-ii-robodis-ii1-100x100.webp)

![pic-dt-robodis-ii-basket-adaption700[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-basket-adaption7001-100x100.jpg)

![pic-dt-robodis-ii-handling-inline-filter700[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-handling-inline-filter7001-100x100.jpg)

![pic-dt-robodis-ii-40batch-filter[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-40batch-filter1-100x100.jpg)

![pic-dt-robodis-ii-sinker-handling-krzer[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-sinker-handling-krzer1-100x100.jpg)

![pic-dt-robodis-ii-40batch-closeup[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-40batch-closeup1-100x100.jpg)

![pic-dt-robodis-ii-robo-led[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-robo-led1-100x100.jpg)

![pic-dt-robodis-ii-sst-cap-11[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-sst-cap-111-100x100.jpg)

![pic-dt-robodis-ii-ph-meter582[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-ph-meter5821-100x100.jpg)

![pic-dt-robodis-ii-mg-0836[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-mg-08361-100x100.jpg)

![pic-dt-robodis-ii-analysis[1] Fully Automated Dissolution System RoboDis II+](https://smarteq-sa.com/storage/2024/11/pic-dt-robodis-ii-analysis1-100x100.jpg)

![llproductsdissolution-onoffline-system-hplc[1] Dissolution HPLC On-/Offline System](https://smarteq-sa.com/storage/2024/11/llproductsdissolution-onoffline-system-hplc1-600x600.webp)

![pic-dissolution-offline-system-pvp-vs[1] Digital Dissolution Offline System](https://smarteq-sa.com/storage/2024/11/pic-dissolution-offline-system-pvp-vs1-600x400.jpg)

![llproductsdissolution-onoffline-system-uv-vis[1] Dissolution On-/ Offline System With UV-Vis](https://smarteq-sa.com/storage/2024/11/llproductsdissolution-onoffline-system-uv-vis1-600x600.webp)

![llproductsdissolution-online-system[1] Dissolution Online System UV-Vis](https://smarteq-sa.com/storage/2024/11/llproductsdissolution-online-system1-600x600.webp)