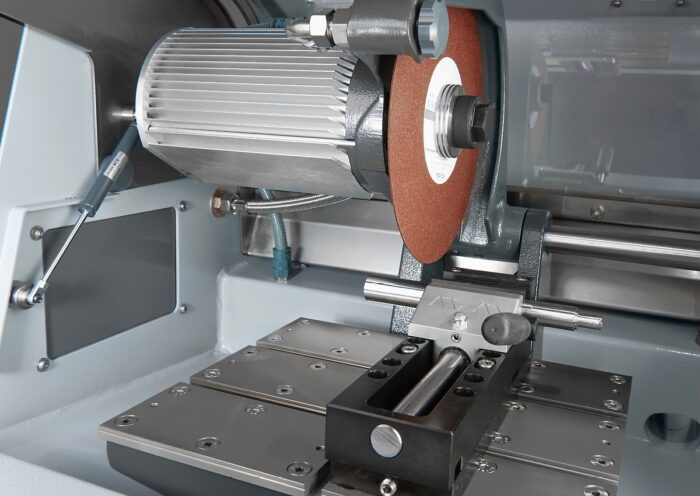

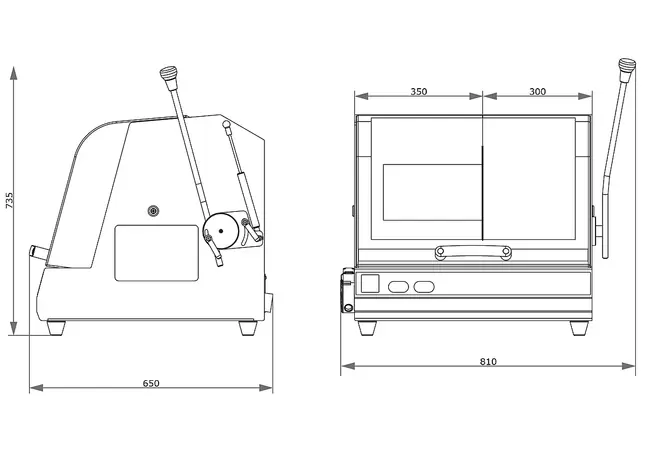

The Qcut 250 M is an especially user-friendly wet abrasive cutting machine with manual cut-off. Opening the machine folds away the hood to the inside so that the whole cutting chamber is easily accessible. The round window opens a wide field of view during the cutting process.

The cutting wheel cooling is integrated directly into the wheel guarding cover. The large, stainless table is equipped with replaceable wearing plates. Transverse grooves allow optimized alignment of clamping vices (e. g. clamping vice 80).

Product Advantages

- Manual vertical movement

- Large cutting chamber

- Opening on left- and righthand side for continuous long parts

- Large table with exchangeable wearing plates

- Hood covering complete width for optimal accessibility

- Easy operation

- Large range of different clamping tools and systems available

- Current safety standard with door interlocking system

- Solid aluminium case construction, powder coated

Features

Fine dynamic cut-off

The manual cutting movement of the Y-axis is executed precisely and jerk-free via lever. Length and angle of the lever are adjustable. Further, the cutting depth can easily be adjusted by using a limiter.

Illumination

Through the large rounded window, the cutting chamber is comfortably visible. For direct lighting, the Qcut 250 M can be equipped with a flexible LED light.

Safety

The integrated standstill monitoring allows opening only when the cutting wheel is not rotating.

Perfect cutting – Cut-off wheels from QATM

Cutting is more reliable, safe and efficient when processed with the right ingredients: knowledge, care and the right choice of consumables and instruments. The Qprep range includes specially developed cut-off wheels for a wide variety of materials and requirements.

- Low thermal influence on the specimen during the cutting process

- Wet abrasive cutting achieves very fine surface finishes after cutting

- Optimal cutting shortens the further preparation process

Fast, Powerful, Flexible – Qtool Clamping devices

Our innovative clamping devices are used to clamp workpieces securely and precisely to ensure exact cutting and grinding processes. There is a wide range of different clamping devices that have been developed for specific applications and workpiece sizes.

- Suitable for regular and irregularly shaped samples

- Fast, repeat-accurate clamping of regularly shaped samples

- Large range of different clamping tools and systems available