The Qcut 250 A is a compact and flexible semi-automatic abrasive cut-off machine with a 254 mm / 10“ cut-off wheel for workpieces or samples up to Ø 95 mm. This machine combines the benefits and speed of a manual cut-off machine with the advantages of an automatic abrasive cutter.

The semi-automatic Qcut 250 A, equipped with a hand lever and automatic lever brake, can be operated with one hand and makes vertical cuts or the positioning of the cut-off wheel easier than before. The cutting table with T-slots is made of stainless steel and can be used either with a dynamic automatic drive (allows pulsed cut) or in manual mode, operated by a hand wheel (traverse cut). Together with the well-proven QATM technology of pulsed cutting, the Qcut 250 A provides excellent cutting results even with the most difficult materials. And having an automatic X-axis allows the Care-Cut (oscillation cut) during a chop cut for large pieces.

For more complex cutting tasks, the Qcut 250 A can be equipped with an optional automatic cross table to perform serial cuts. Axes are monitored by travel measuring during set up and operation.

Product Advantages

- Manual Y-axis with electromechanical lever brake

- Care-Cut: facilitates gentle cutting

- 7″ Touch-Screen user interface with intuitive QATM user software

- Automatic travel X-axis – manual travel via hand wheel

- Cutting-force dependent feed control (X-axis)

- Superior LED illumination of cutting chamber

- Parallel setting of wheel guard during cutting sequences increases cutting capacity

- Opening on both sides for long parts

Features

Fine dynamic cut-off

With the manual cutting movement, the cutting force is regulated through a set of gears. The cut is thereby yerk-free and more precise. The easy-to-use lever brake fixes the cutting disc in any position.

Horizontal movement

The manual horizontal or automatic movement allows cutting long parts longitudinally and easy positioning of the sample below the cut-off wheel. In pulsed cutting mode the sample material is cut particularly gently.

Intuitive control software

The new control software with integrated, extensive maintenance menu makes the operation simple and comfortable.

Automatic cross feed

The automatic Z-axis can be adjusted with 0.1 mm precision for parallel cuts.

Perfect cutting – Cut-off wheels from QATM

Cutting is more reliable, safe and efficient when processed with the right ingredients: knowledge, care and the right choice of consumables and instruments. The Qprep range includes specially developed cut-off wheels for a wide variety of materials and requirements.

- Low thermal influence on the specimen during the cutting process

- Wet abrasive cutting achieves very fine surface finishes after cutting

- Optimal cutting shortens the further preparation process

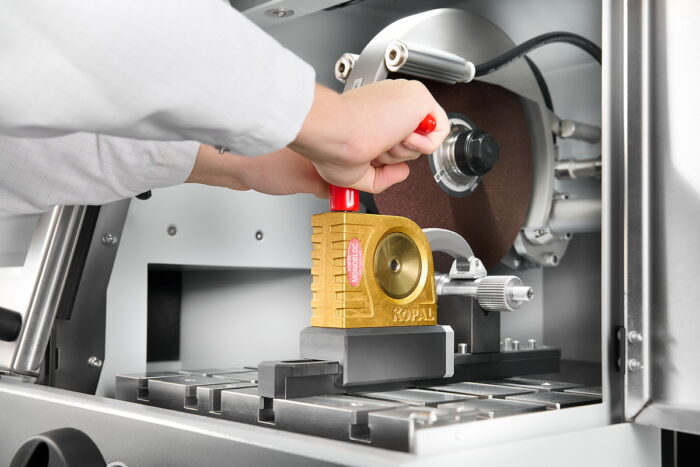

Fast, Powerful, Flexible – Qtool Clamping devices

Our innovative clamping devices are used to clamp workpieces securely and precisely to ensure exact cutting and grinding processes. There is a wide range of different clamping devices that have been developed for specific applications and workpiece sizes.

- Suitable for regular and irregularly shaped samples

- Fast, repeat-accurate clamping of regularly shaped samples

- Large range of different clamping tools and systems available