The Qcut 500 A is the powerhouse of the large cut-off machine family. Equipped with a highly dynamic axis drive and automatic trave cut/chop cut functions, the system cuts large components with exceptional precision, minimal contact, and outstanding speed.

- Fast, powerful cuts: The highly dynamic axis drive allows rapid traverses of up to 80 mm/s and greatly reduces cutting time

- Versatile applications: Cutting of particularly long samples is easily possible thanks to side openings on both sides

- Multi-Position Process (MPP): Simultaneous positioning and automatic cutting of different components on the machine table

1. Ergonomic control panel

- Large 12.1“ industrial touchscreen with intuitive QATM software

- Quick setup, control of all axes with joystick

2. Robust machine body

- Sturdy powder-coated aluminum construction

- Integrable recirculating cooling unit

- Automatic central lubrication of the axes

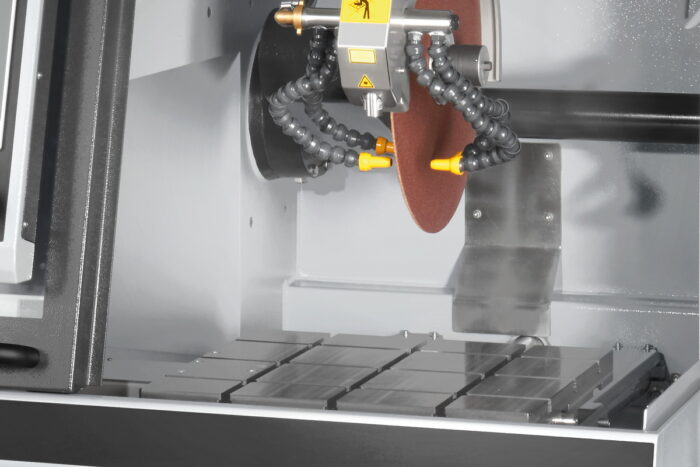

3. Large machine table

- Made of stainless steel with integrated longitudinal and cross T-slots

- Secure clamping of complex workpiece shapes using the T-slot table or Easy clamping system

- Dimensions: 550 x 500 mm (with Z-axis W x D), 700 x 500 mm (without Z-axis W x D)

- Load capacity: up to 400 kg

- Travel: X: 345 mm, Y: 200 mm, Z: 150mm

4. Large cutting chamber

- Large sliding door provides easy access and visibility

- Side swing door for convenient access to cutting chamber

- Side openings on the right and left for long samples

- Break-resistant LED interior lighting

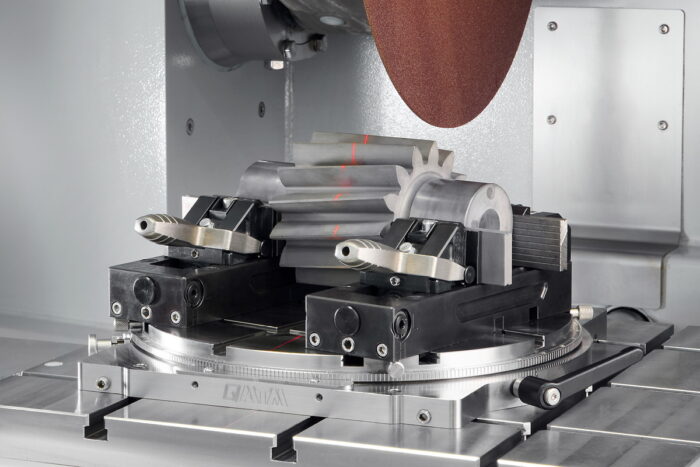

5. Optimized swivel arm

- Highly efficient cooling system

- Increased cutting capacity thanks to parallel guided cut-off wheel guard

- Laser alignment aid for easy workpiece positioning

Cut-off machine Qcut 500 A Features

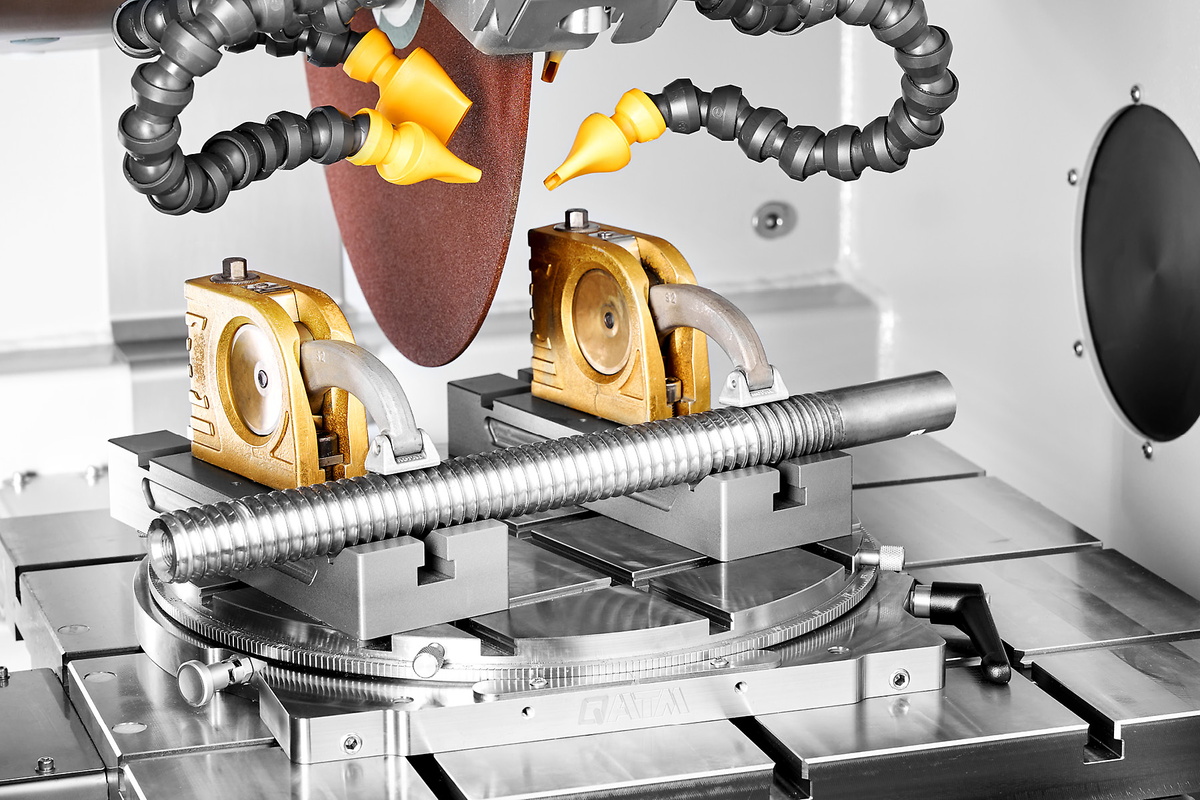

Stainless steel machine table

Spacious machine table enables precise work even under heavy loads.

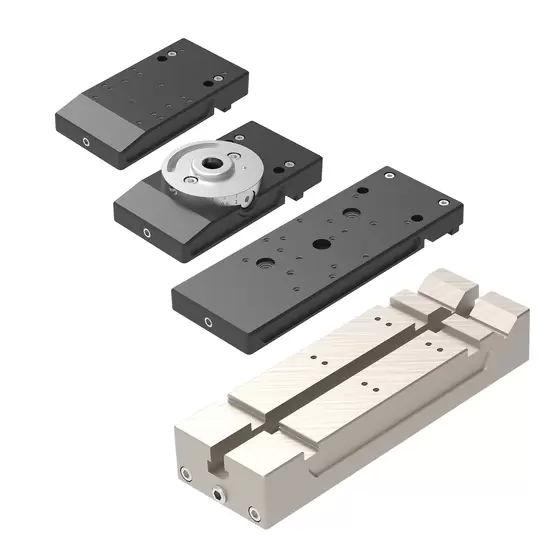

- Integrated T-slots for the Easy clamping system for quick mounting of clamping tools

- Efficient and reliable fixation of complex geometries using clamping devices

- Load capacity up to 120 kg (including clamping devices)

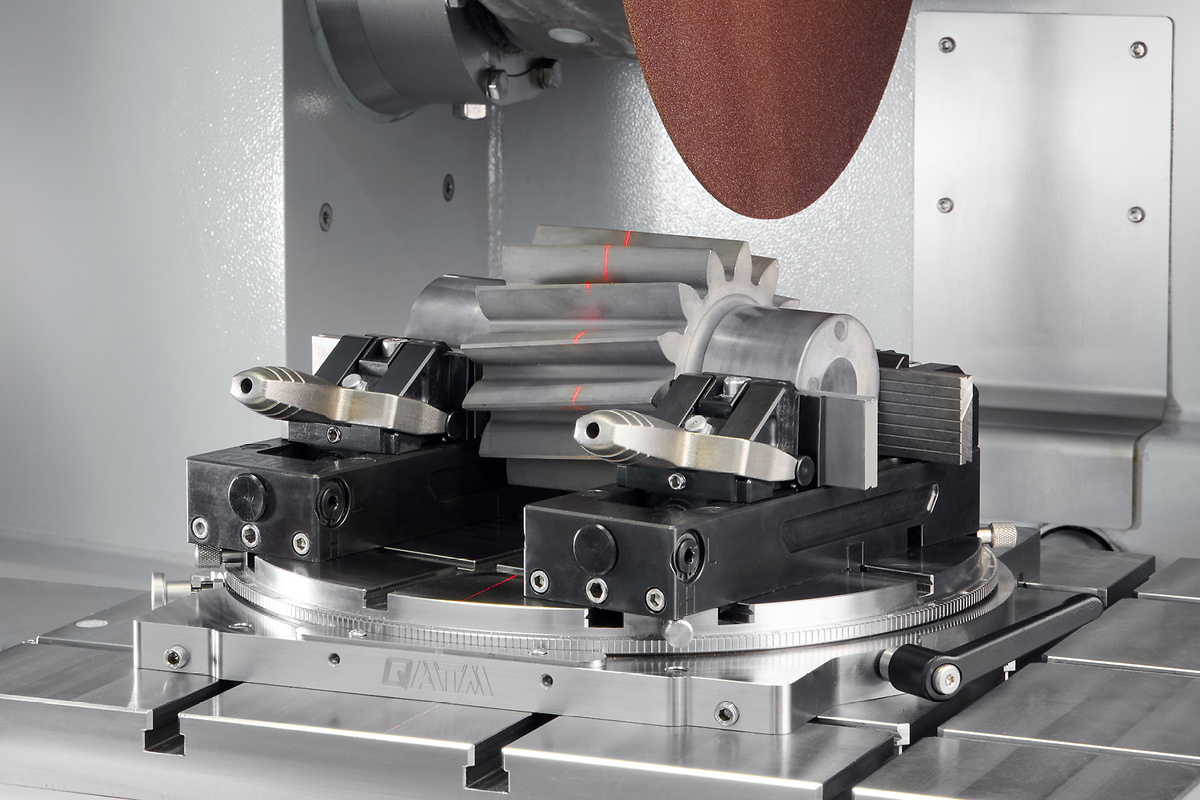

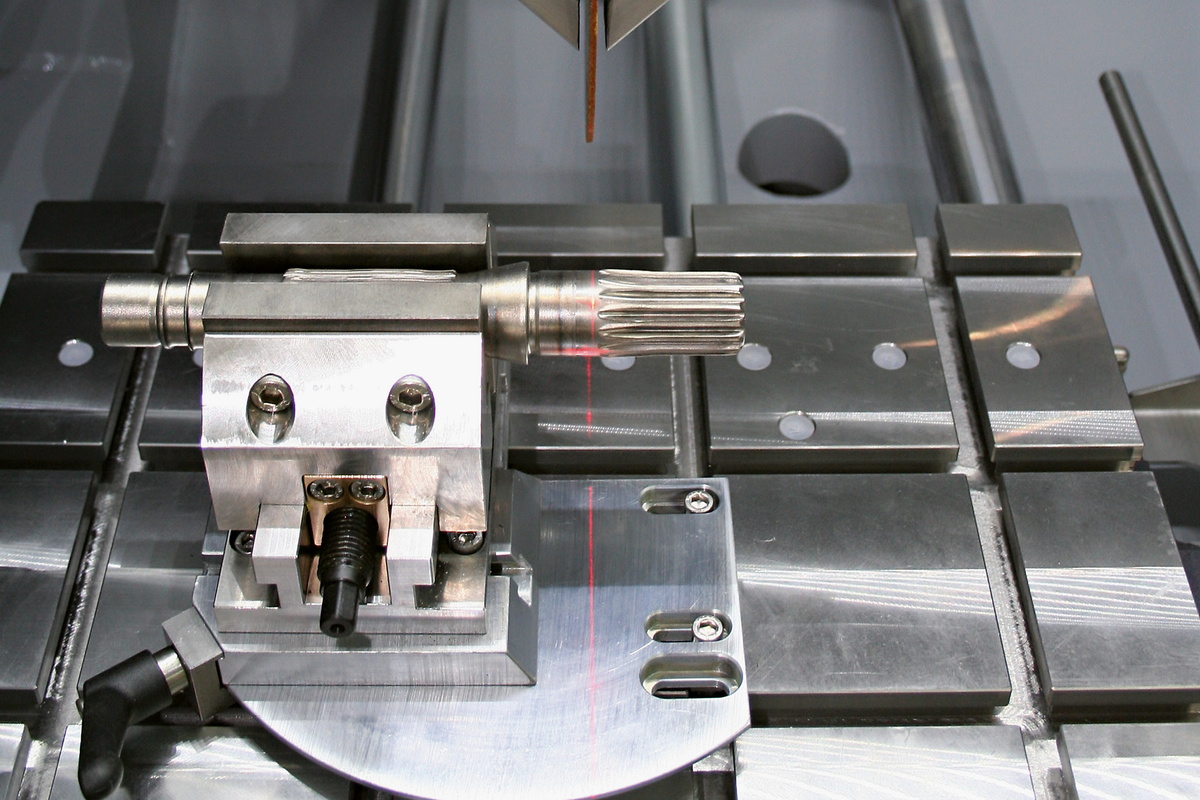

Laser alignment

Optional laser alignment projects the cutting line directly onto the workpiece, enabling precise positioning and exact cut placement.

- Easy positioning of workpieces

- Precise clamping without much effort

Robust machine with large cutting chamber

Robust, powder-coated aluminum machine body features a large sliding door with scratch-resistant laminated safety glass and convenient side access door.

- Machine body with integrable recirculating cooling unit and automatic central lubrication

- Large cutting chamber access with safety interlock — doors open only when cut-off wheel is stationary

- Side opening on the right for long samples

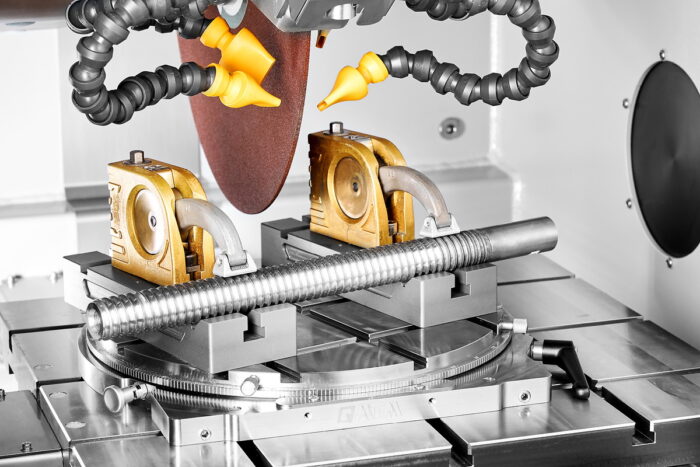

Precision cross feed

The table-integrated Z-axis maintains consistent cutting height while the automatic cross feed with serial cutting function delivers precise parallel cuts.

- Simple and intuitive serial cutting

- The multi-position process (MPP) allows more complex serial cutting to be carried out

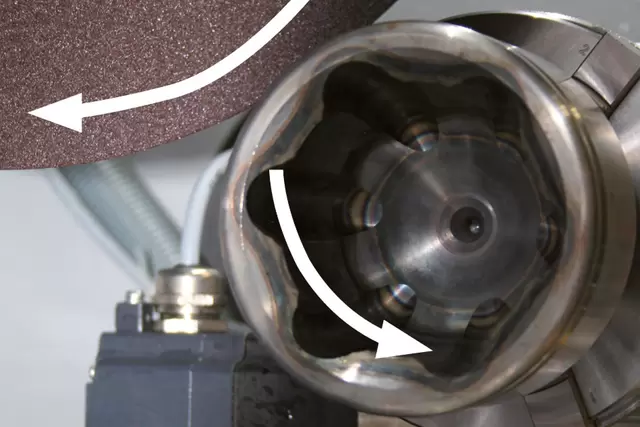

Rotation tool

The optional rotation tool features a vertical rotary feed parallel to the wheel with software-controlled angle input.

- More uniform cutting surfaces and cutting quality

- Cutting time is halved for rotationally symmetrical parts

- Protects against cut-off wheel run-out

Intuitive and easy operation

Large 10.1” industrial touchscreen with intuitive QATM user software and joystick.

- Easily manage process parameters and create customer-specific maintenance tasks (200 user programs can be saved)

- Parameters such as feed rate, travel distance, and cutting force can be changed during automatic operation

Pulsed cutting

For thick and difficult-to-cut materials, the adjustable automatic pulsed cutting provides gentle sectioning with optimal cooling of the cut interface.

- Enhanced cutting results for larger components

- Superior cooling of contact surfaces

Cutting force dependent feed control (X- and Y-Axis)

The feed rate automatically decreases when cutting force reaches a preset limit, protecting the machine, sample, and clamping tools from overloading while ensuring time savings through variable feed control.

- Time savings thanks to variable feed rate

Cut-off machine Qcut 500 A Accessories

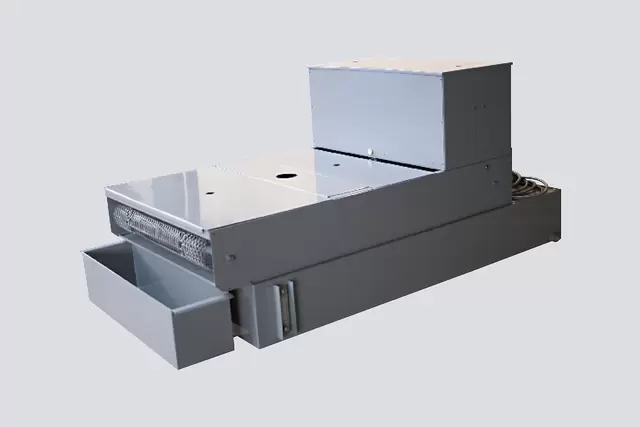

Recirculation cooling unit

Compact, integrable cooling system for standard applications.

- Can be integrated into the housing and extended

- Multi-chamber filtration

- Inlet sieve with filter bag (see consumables)

Belt filter system

Large cooling and filter system for continuous operation, e.g. in serial applications.

- Tank size: 285 l

- Filtering capacity: 100 l/min (referring emulsion)

- Pump capacity: 100 l/min

Centrifugal Separator

Work safety: Working environment with improved air quality.

- Removes coolant mist

- Purifies the air and increases visibility

- Exhaust power 452 or 500 m3/h depending on voltage