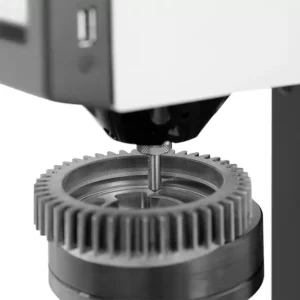

Simple and efficient rockwell hardness testing

The Qness 150 CSA+ incorporates the best of all proven concepts and practices: the versatility of an automatic hardness tester and the speed of our Rockwell testers.

A fully automatic XY slide will guarantee high precision hardness testing. It is ideal for fully automatic series and progression tests on parts with identical test heights. However, individual tests can be performed, too.

Product Advantages

- Large test force range (1kg – 250kg)

- Automatic 3-axis control

- Short cycle times

- Identical sample tests

- Robust, welded steel frame

- Infinitely adjustable test table height

Qness 150 CS/CSA ECO Pedestal

No suitable table in the testing area? No problem! The Qness 150 CS/CSA ECO matches perfectly with the machine’s optional pedestal. The superior-quality subframe is color-matched to the hardness testing device. The machine pedestal includes a spacious, lockable compartment in which to store accessories. Beechwood (40 mm thick) with a spindle bore.

Maximum QATM-Standard precision

QATM configures the Rockwell hardness tester Qness 150 CS and CSA+ with a direct, ultra-precise HEIDENHAIN depth-gauging system, positioned exactly on the axis of the indenter. This omits measurement inaccuracies caused by deformation in the system. Another unbeatable benefit: Indenting depth can be gauged directly – and can be easily calibrated in accordance with the latest Rockwell norms.

Revolutionary 3D operating concept

Intuitive, clearly organized and professional: Qpix Control2 next-generation hardness testing software, developed based on customer feedback and input for maximum user-friendliness. 3D imaging and a whole range of easily understood control elements and views included in the software. It sets new standards in hardness testing.